Upper portion flange supporting mechanism used for ethylene cracking furnace decoking

A technology of ethylene cracking furnace and supporting mechanism, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve problems such as bending and sinking displacement furnace tubes, and achieve the advantages of avoiding bending, prolonging service life, convenient operation and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

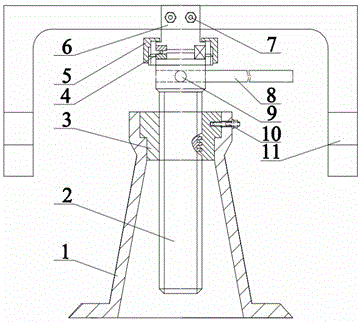

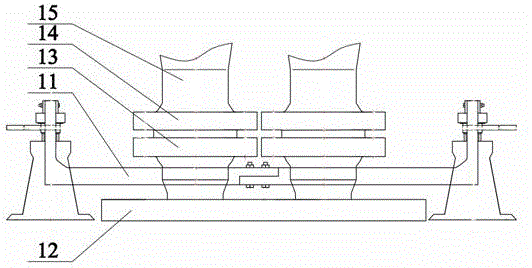

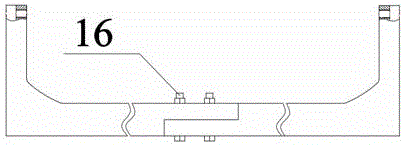

[0026] Such as figure 1 , 2 As shown, an upper flange support mechanism for coke cleaning of an ethylene cracking furnace includes two lifting bodies, and the lifting bodies include a base 1 , a nut 3 , a screw 2 , a holder cup 6 , a thrust bearing 4 and a moving arm 11 . The base 1 is provided with a cavity, the nut 3 is fixed on the top of the cavity of the base 1, the lower part of the screw rod 2 is inserted in the cavity of the base 1, and is connected with the nut 3 by threads, and the upper diameter of the screw rod 2 is A handle jack 9 is opened in the direction, and a handle 8 is inserted into the handle jack 9, and the handle 8 is located above the base. By applying a thrust to the handle 8, a bending moment is generated to make the screw 2 rotate relative to the base 1. The screw rod 2 is movably connected with the support cup 6 through the thrust bearing 4, the thrust bearing 4 is arranged above the screw rod 2, the fixed ring of the thrust bearing 2 is fixedly co...

Embodiment 2

[0029] In order to ensure that the whole device is more stable during the working process, the lifting body also includes a limit sleeve 5 , which is sleeved on the outside of the thrust bearing 4 and screwed to the top of the screw rod 2 . The screw rod 2 and the holder cup 6 are further fixed by the limit sleeve 5, which well limits the horizontal and vertical displacement of the holder cup 6 relative to the screw rod 2, and ensures that the whole device is more stable during the working process.

[0030] In order to ensure that the nut 3 is relatively fixed to the base 1, the top of the inner wall of the base 1 is a stepped structure, the outer wall of the nut 3 is a stepped structure, and the step on the top of the inner wall of the base 1 is matched with the step of the outer wall of the nut 3, and the base 1 and the outer wall of the nut 3 are matched. Correspondingly, the nut 3 is provided with a threaded hole, and the base 1 and the nut 3 are fixedly connected by the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com