Thread stand of waistband extension machine

A waist-pulling machine and thread stand technology, which is applied to sewing machine components, bobbin insertion rod components, textiles and papermaking, etc., can solve the problems of time-consuming, labor-intensive, inconvenient operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

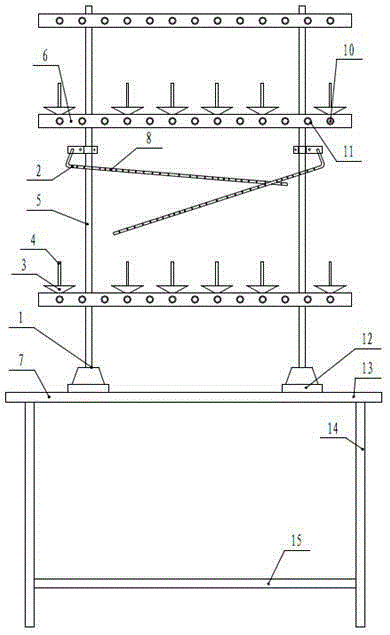

[0015] Such as Figure 1~2 Shown, a kind of wire frame of waist-drawing machine comprises frame 1, has the thread take-up lever 2 of thread take-up hole 8 and is provided with the thread lever 4 of tray 3, and described frame 1 comprises support bar 5 and is fixedly connected in A plurality of placement platforms 6 on the support rod 5, the support rod 5 is fixedly connected to the support table 7, the support table 7 is installed on the right side of the waist pulling machine, and the thread take-up rod 2 is rotatably connected to the On the support rod 5, the wire rod 4 is connected to the placement table 6.

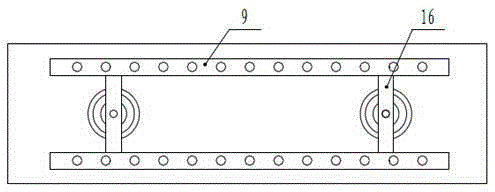

[0016] Preferably, the above-mentioned placing table adopts two pieces of angle steel 9 to be placed front and back, fixedly connected by the left and right beams 10 in the middle, and the holes for installing the support rods 5 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com