Connection structure of frame steel beams and composite floor slab

A technology for superimposing floor slabs and connecting structures, which is applied to slabs, building components, building structures, etc., can solve problems such as increasing manpower, material resources, and financial resources, difficulty in making and installing steel columns, and increasing construction costs. Flexibility, high machining accuracy, and the effect of reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below with reference to accompanying drawing and embodiment:

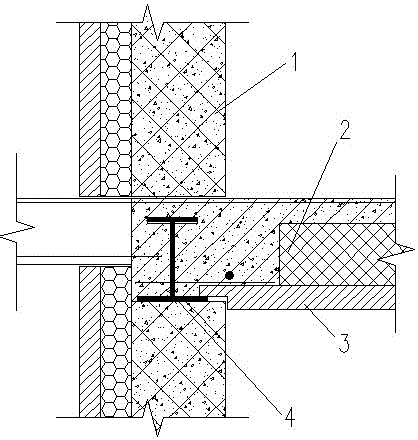

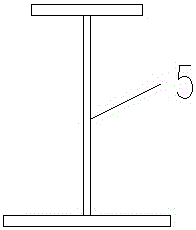

[0027] attached Figure 1-3 It can be seen that a connection structure between a frame steel beam and a laminated floor includes a connection structure between a middle frame steel beam and a laminated floor and a connection structure between a side frame steel beam and a laminated floor, and is characterized in that:

[0028] The upper and lower flange plates of the middle frame steel beam are parallel to each other; the width of the lower flange plate of the middle frame steel beam is 25-30mm wider than the edge of the upper flange plate of the middle frame steel beam;

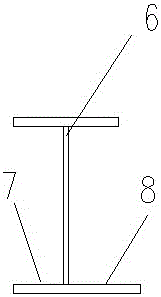

[0029] The upper and lower flanges of the side frame steel beams are parallel to each other;

[0030] The outer sides of the upper and lower flange panels of the side frame steel beams are flush; to facilitate the installation of exterior wall panels;

[0031] The width of the lower flange pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com