Hydraulic solid wedge deflection tool

A deflector, a solid technology, applied in directional drilling, drilling equipment and methods, earthwork drilling and production, etc., can solve the problems of reducing operating efficiency, wellbore scrapping, failure to reach the predetermined position, etc., to improve work reliability, The effect of avoiding mis-setting accidents and eliminating potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

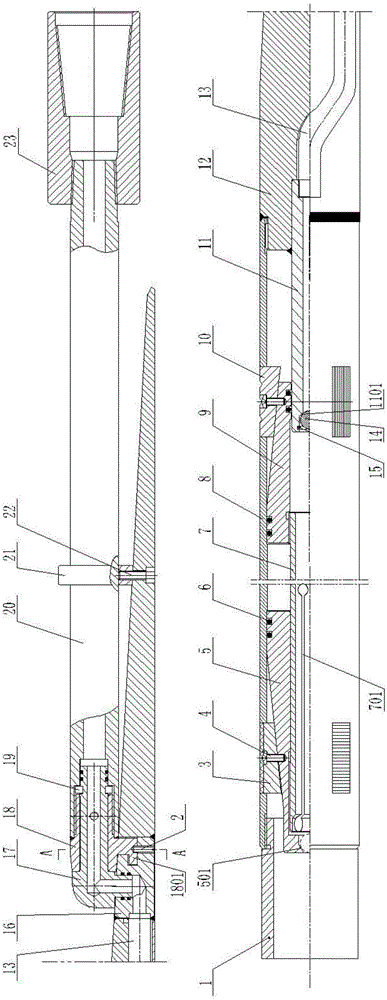

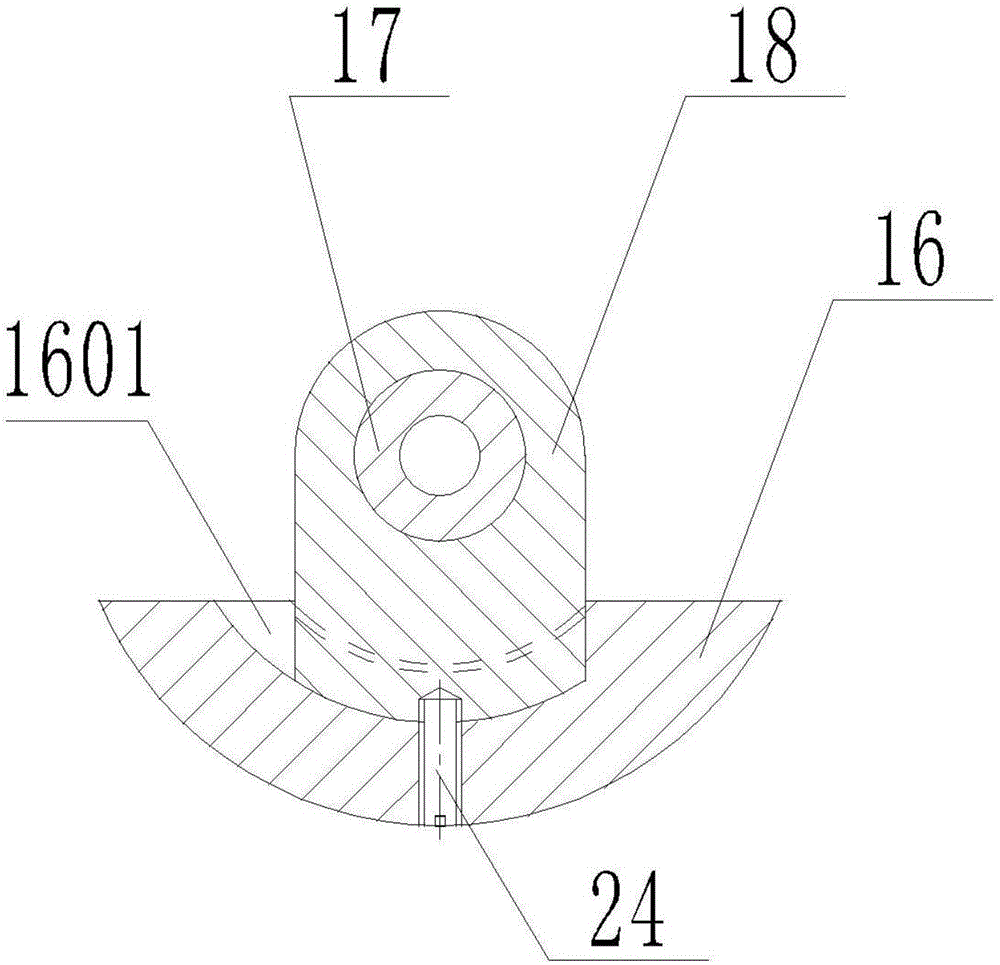

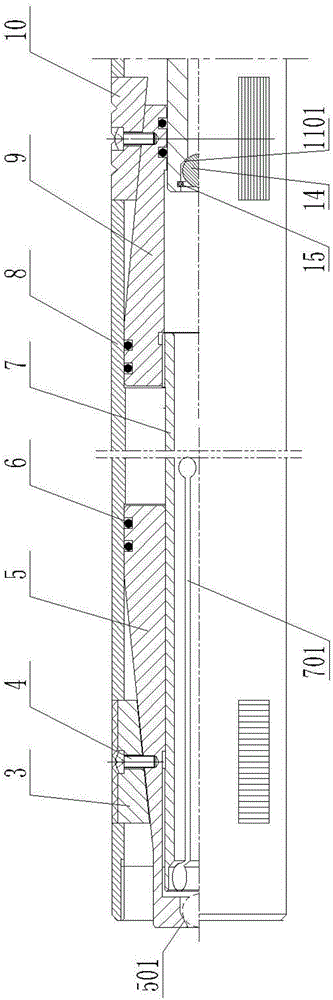

[0025] Such as Figure 1-Figure 3 As shown, the present invention relates to a hydraulic solid whip guide, including a tubular feeder 20, the upper end of the feeder 20 is screwed with an upper joint 23, and the lower end of the feeder 20 is sequentially connected with a whipstock angle iron 12 and the setting and anchoring device. A catheter 13 connecting the inner hole of the feeder 20 and the inner cavity of the setting and anchoring device is provided in the inclined iron 12 of the whip guide. At the lower end of the feeder 20, a hook body 18 is screwed and welded and fixed, and an elbow body 17 is inserted into the hook body 18. The upper end of the elbow body 17 penetrates the central hole of the hook body 18 and is sealed and inserted into the feeder 20. In the central hole of the elbow body 17, an annular groove is provided on the upper part of the outer edge of the elbow body 17, and a split snap ring 19 is provided in the annular groove between the upper end of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com