Rotation-type pulse detonation engine

A pulse detonation and engine technology, applied in mechanical equipment, continuous injection devices, etc., can solve the problems of hindered development of large aircraft, delayed development and construction, and unknown fate, and achieve simple structure, low cost, and good environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

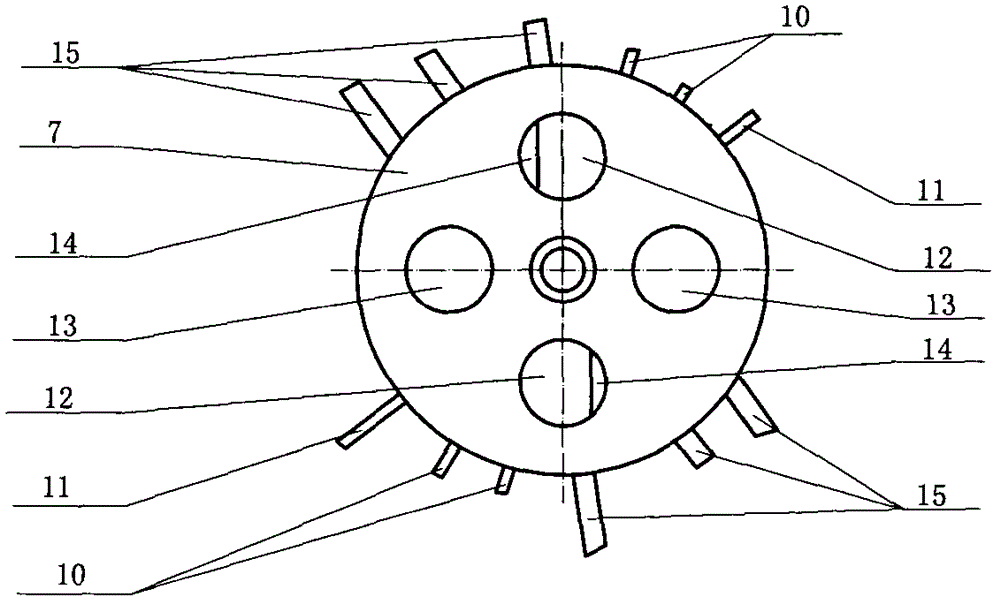

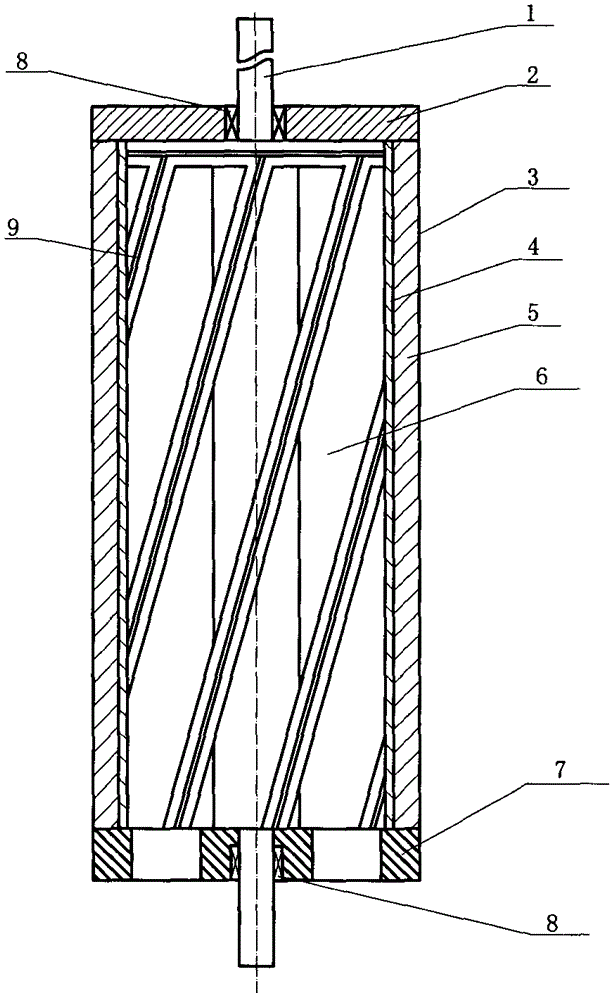

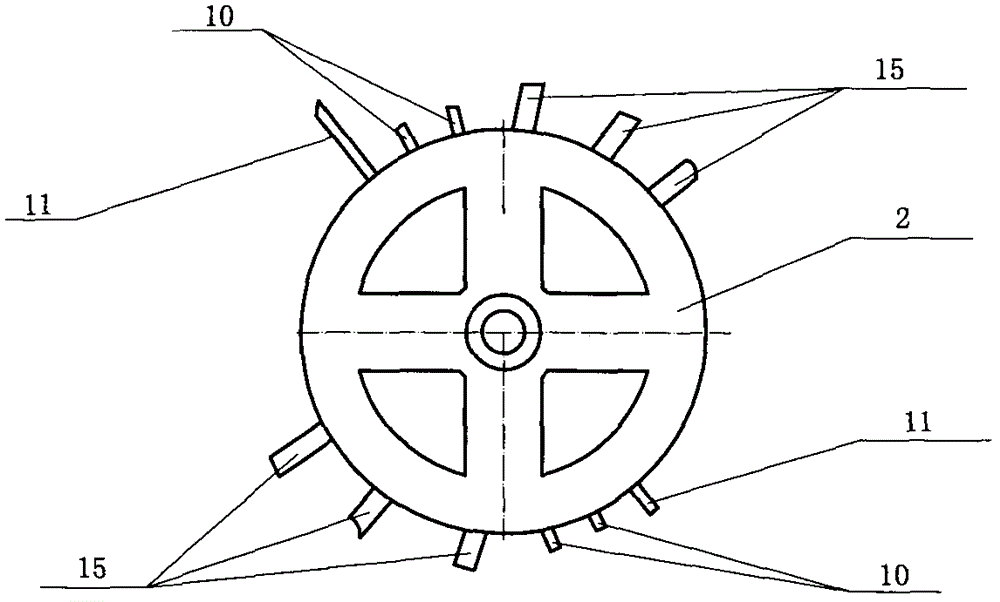

[0033] to attach figure 1 - attached Figure 14 For example:

[0034] The cyclic operation period of the present invention is subdivided into five processes: air intake, exhaust, fuel injection, ignition, detonation, and injection.

[0035] The present invention is mainly composed of output shaft 1, cylinder 3, rotor 6, bearing fixed disk 2 and sealing disk 7.

[0036] The cylinder 3, the rotor 6 and the sealing disk 7 form a plurality of fan-shaped detonation chambers. When the detonation chambers are transferred to the air inlet 15, the detonation chambers are transferred to the exhaust port 12 at the same time. , the detonation chamber takes in air, and at the same time, the intake air pushes the waste gas in the detonation chamber to be discharged from the exhaust port 12; after the air intake is completed, the detonation chamber has been transferred to the fuel injection port 10 for fuel injection ; After fuel injection, the detonation chamber has just been transferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com