Parallel automobile engine air intake system

A technology of automobile engine and air intake system, which is applied to engine components, machines/engines, charging systems, etc., can solve problems such as low engine efficiency and exhaust pollution, and achieve the goal of reducing pollution, increasing air intake, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

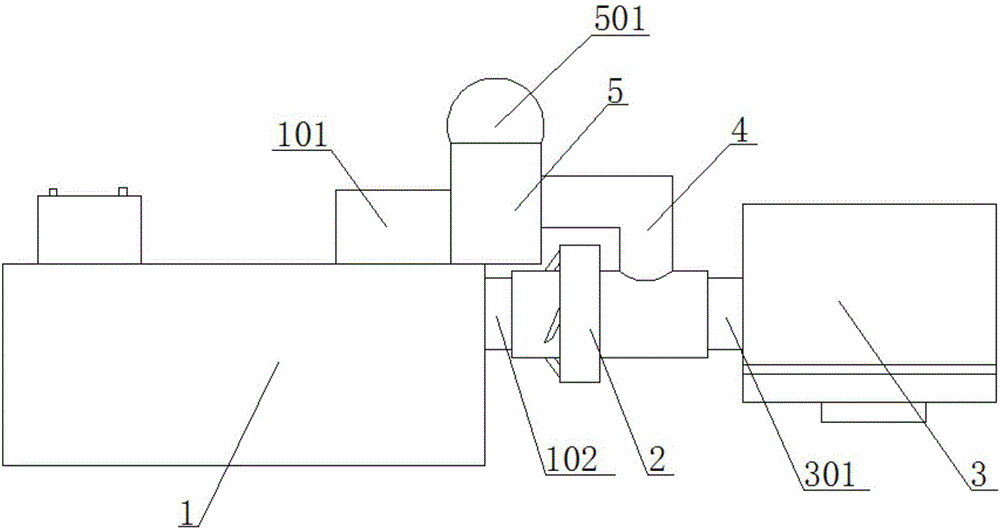

[0033] Such as figure 1 , the present invention proposes a parallel automobile engine air intake system, including an engine 1, an air intake pipe 2 and an air filter 3, and also includes a body, which is included on the air intake pipe 2 of an existing naturally aspirated engine or the air filter A bypass air inlet is opened on the shell of the air outlet 301 side of the cleaner 3 to connect the outlet of the air supercharger 5; the inlet of the above air supercharger 5 is connected with a second air filter 501 to form a natural air intake The main body of the system and the supercharged intake system work in parallel; the operating state of the above-mentioned air supercharger 5 is controlled by the operating state of the above-mentioned engine 1 .

[0034] Since the air supercharger 5 takes in air through the second air filter 501 installed by itself, it avoids the defect of insufficient air intake caused by sharing an air filter with the original natural air intake system....

Embodiment 2

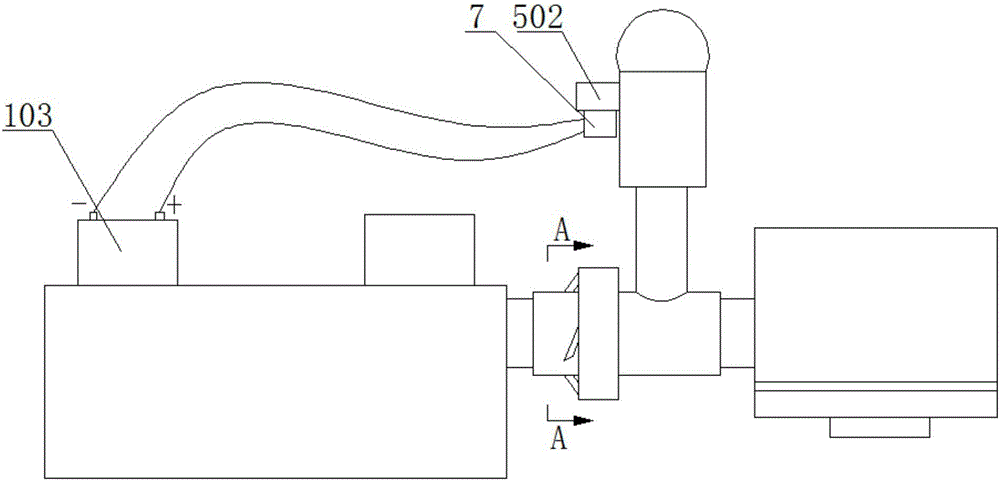

[0040] Such as figure 2 The above-mentioned air supercharger 5 is driven by electricity, and the above-mentioned air supercharger 5 is arranged at one end of the water tank of the engine.

[0041] At this time, the air input by the engine air inlet 102 flows through the radiator of the engine 1 and then enters the engine 1 . This structure can not only dissipate heat from the water tank, but also increase the intake air temperature.

[0042] The motor 502 of the above-mentioned air supercharger 5 is connected to the storage battery 103 through a special-purpose controller 7, and the throttle sensor or the throttle mechanism displacement sensor or the engine speed sensor is connected to the special-purpose controller 7 to control the motor 502 of the above-mentioned air supercharger 5 speed.

[0043] The air booster 5 is driven by a motor 502 , which is electrically connected to the battery 103 ; a controller 7 is connected in series between the motor 502 and the battery 103...

Embodiment 3

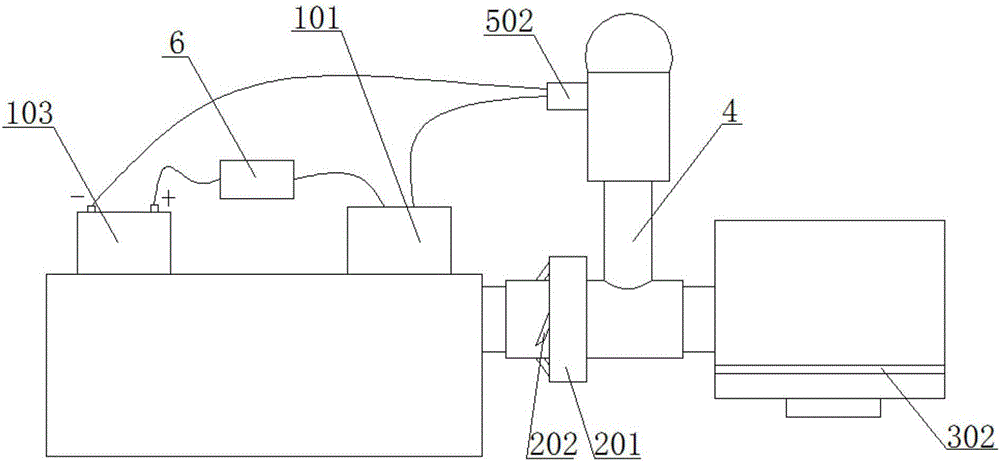

[0049] Such as image 3 , the output end of the generator 101 of the above-mentioned engine 1 is divided into two paths, one path is directly connected to the motor 502 of the above-mentioned air supercharger 5, and the other path is connected to the engine battery 103 through the isolator 6.

[0050] Above-mentioned air supercharger 5 is driven by motor 502, and the output terminal of generator 101 is electrically connected with the positive pole of motor 502 and storage battery 103 respectively, and isolator 6 is also connected in series between generator 101 and storage battery 103; The motor 502 is electrically connected. The above-mentioned isolator 6 is a one-way conductive isolator.

[0051] This structure adopts the way that the generator 101 directly supplies power to the motor 502 , and controls the start-stop and speed of the air supercharger 5 through the current and voltage changes of the generator 101 .

[0052] This structure enables the generator 101 to not o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com