Air cleaner for engine

An air filter and engine technology, applied in the field of vehicle air purification, can solve problems such as exhaust pollution and low engine efficiency, and achieve the effects of reducing pollution, reducing energy consumption, and increasing air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

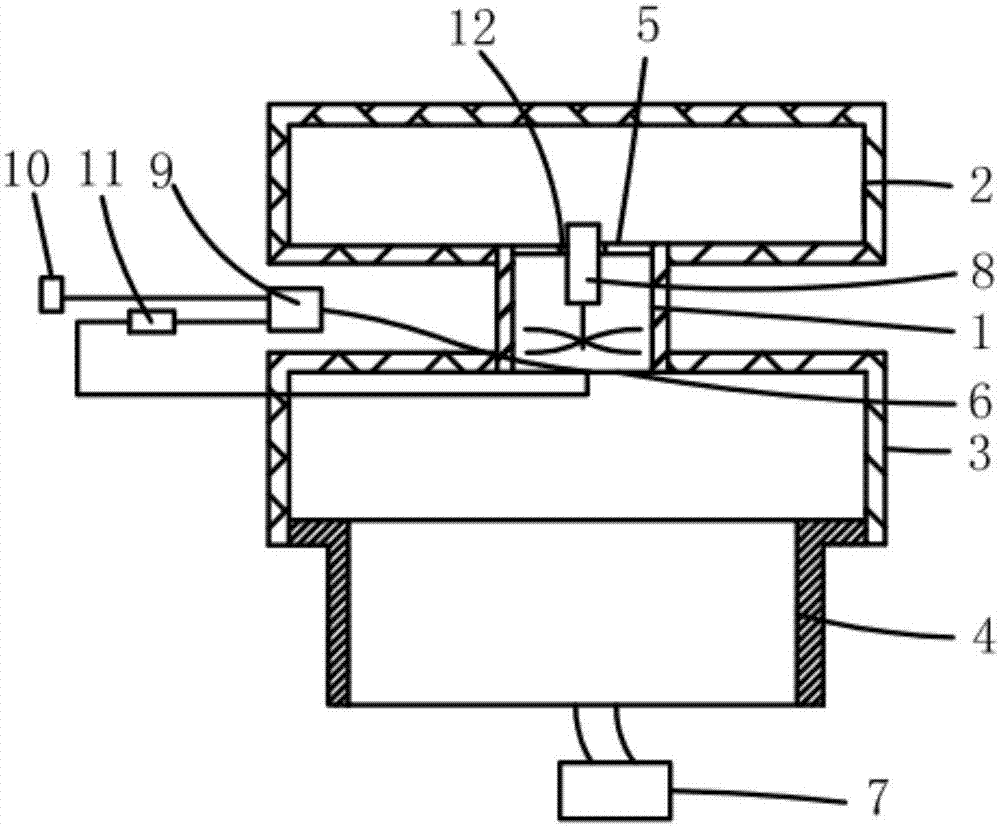

[0036] like figure 1 As shown, a kind of engine air filter comprises a blower 1, a main air filter 2, a secondary air filter 3 and an air outlet 4, and the shell of the blower 1 is provided with an air inlet 5 and an air outlet 6 , the blower is a centrifugal fan,

[0037] The main air filter 2 is directly connected to the shell of the blower 1, the main air filter 2 communicates with the air inlet 5, the secondary air filter 3 is directly connected to the shell of the blower 1, and the secondary air filter 2 communicates with the air outlet 6,

[0038] The inside of the main air filter 2 and the auxiliary air filter 3 are communicated through the blower 1, the air outlet 4 is located on the auxiliary air filter 3, and the air outlet 4 is connected to the engine 7;

[0039] The motor 8 of the blower 1 is controlled by a motor controller 9, and the motor controller 9 is arranged outside the air filter;

[0040] The motor 8 of the blower 1 is connected to the generator 10 thro...

Embodiment 2

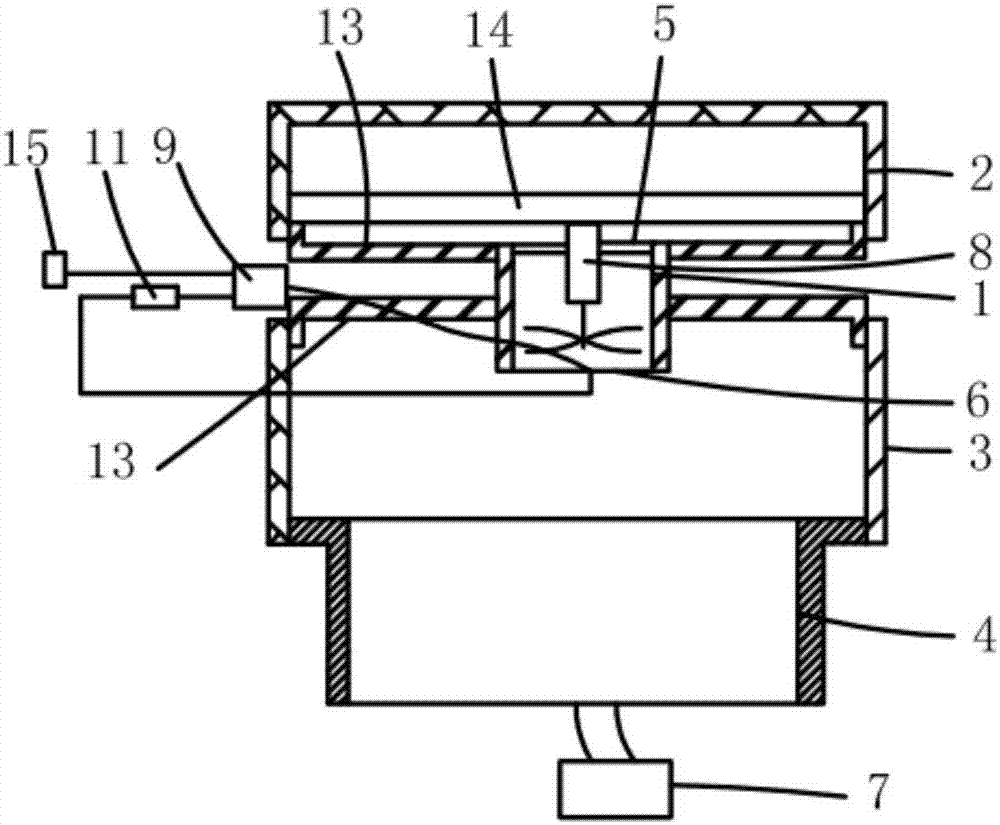

[0045] like figure 2 As shown, a kind of engine air filter comprises a blower 1, a main air filter 2, a secondary air filter 3 and an air outlet 4, and the shell of the blower 1 is provided with an air inlet 5 and an air outlet 6 , Blower 1 is an axial flow fan,

[0046] The main air filter 2 is connected to the shell of the blower 1 through a main body 13, the main air filter 2 communicates with the air inlet 5, the secondary air filter 3 is connected to the shell of the blower 1 through a main body 13, and the secondary air filter 3 Connected with air outlet 6,

[0047] The inside of the main air filter 2 and the auxiliary air filter 3 are connected through the blower 1, the air outlet 4 is located on the auxiliary air filter 3, and the air outlet 4 is connected to the engine 7;

[0048] Also includes a cooling water tank 14, the cooling water tank 14 is arranged between the main air filter screen 2 and the air inlet 5;

[0049] The motor 8 of the blower 1 is controlled by...

Embodiment 3

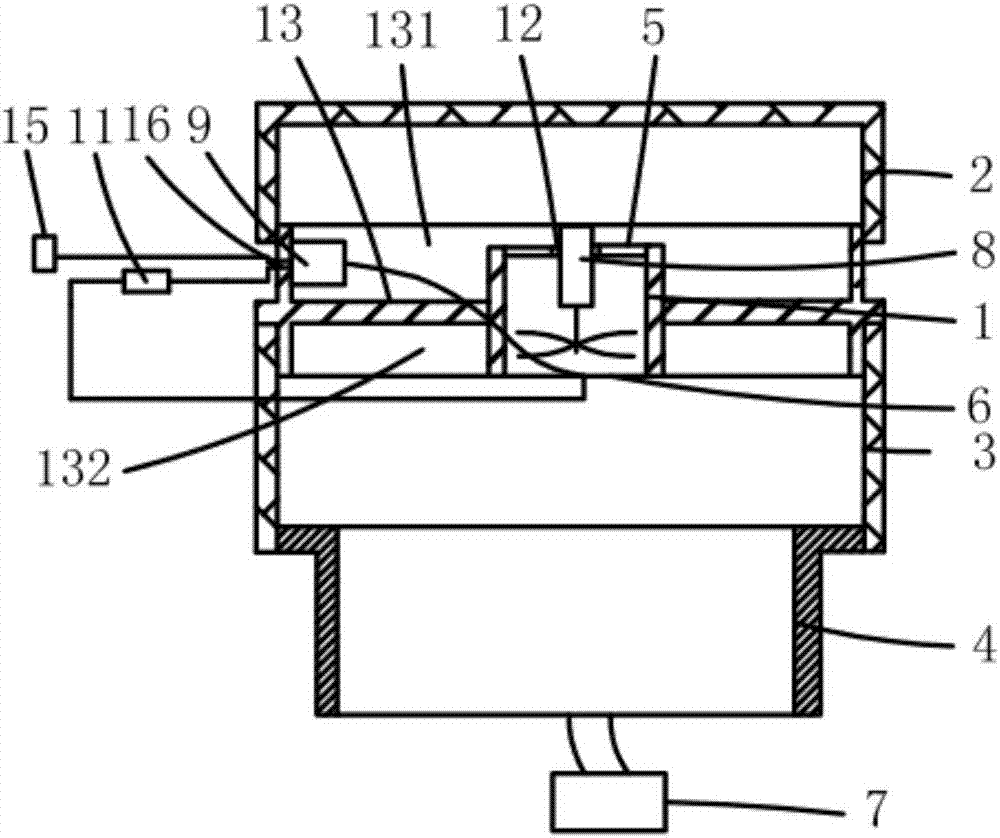

[0054] like image 3 As shown, a kind of engine air filter comprises a blower 1, a main air filter 2, a secondary air filter 3 and an air outlet 4, and the shell of the blower 1 is provided with an air inlet 5 and an air outlet 6 , blower 1 is a turbocharger,

[0055] The main air filter 2 and the auxiliary air filter 3 are connected to the shell of the blower 1 through the same main body 13, the main air filter 2 is connected to the main body 13 through a main body air inlet chamber 131, the main air filter 2 and the air inlet The tuyere 5 is connected, the secondary air filter 3 is connected to the main body 13 through a main body air outlet chamber 132, the secondary air filter 3 is connected with the air outlet 6,

[0056] The inside of the main air filter 2 and the auxiliary air filter 3 are communicated through the blower 1, the air outlet 4 is located on the air outlet chamber 131 of the main body, and the air outlet 4 is connected to the engine 7;

[0057] The motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com