Telescopic sleeve hydraulic cylinder unloading device of mining dump vehicle

A mining dump truck and unloading device technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of oil cylinder bottom falling off, unable to use limit device, high pressure, etc., to achieve the effect of stroke limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

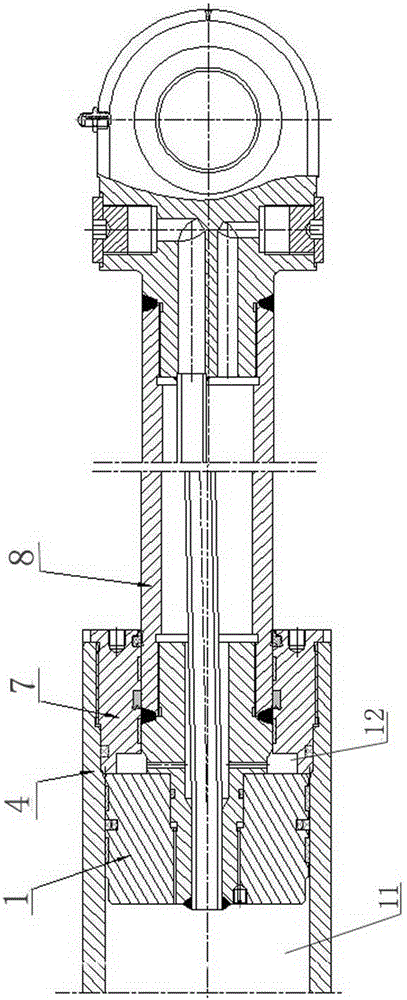

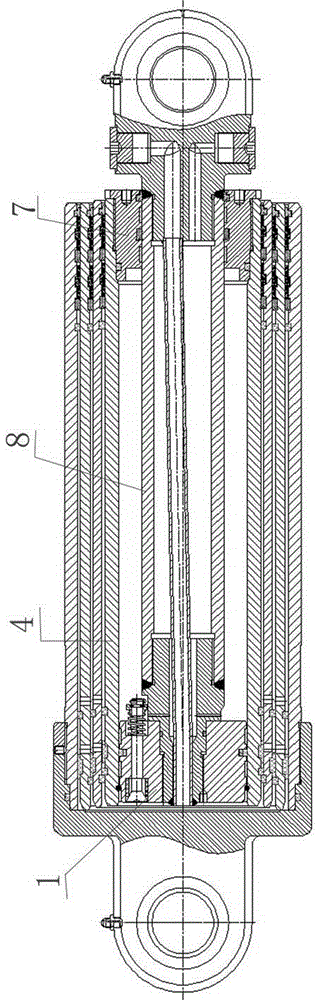

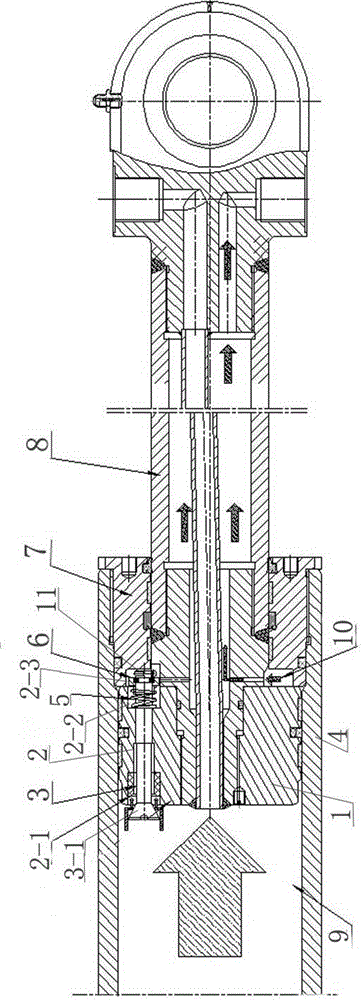

[0019] The present invention as figure 2 , image 3 shown.

[0020] A telescopic sleeve hydraulic cylinder unloading device for a mining dump truck, comprising a hydraulic cylinder piston 1, a final cylinder barrel 4, a guide sleeve 7, and a final piston rod 8, and an unloading device is installed on the hydraulic cylinder piston 1, Wherein the unloading device is arranged along the movement direction of the hydraulic cylinder piston 1 .

[0021] The unloading device is provided with a through hole 2 on the hydraulic cylinder piston 1 along the moving direction of the hydraulic cylinder piston 1, and a guide pin 3 is arranged in the through hole 2, and the tail end of the guide pin 3 is a dovetail cone 3- 1. The guide pin shaft 3 passes through the through hole 2 and is covered with a spring 5. The spring 5 is provided with a spring seat 6 outside the spring seat 6, and the guide pin shaft 3 is fixed by a nut 11 outside the spring seat 6.

[0022] The through hole 2 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com