Hydro-pneumatic spring

A technology of oil-pneumatic springs and oil cylinders, which is applied in the direction of springs, spring/shock absorbers, gas-hydraulic shock absorbers, etc., can solve the problems of large impact, large suspension stiffness, and low vibration energy absorption, and achieve high cross-country speed, The effect of good ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

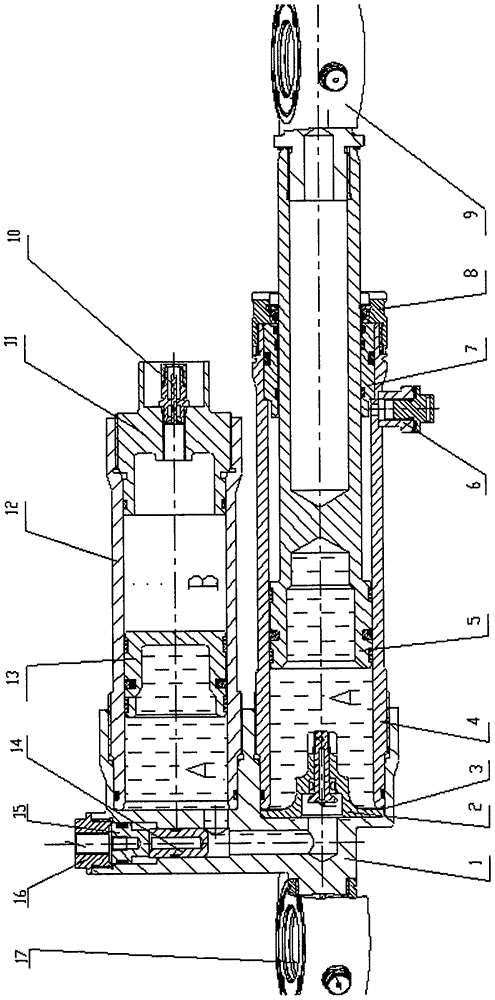

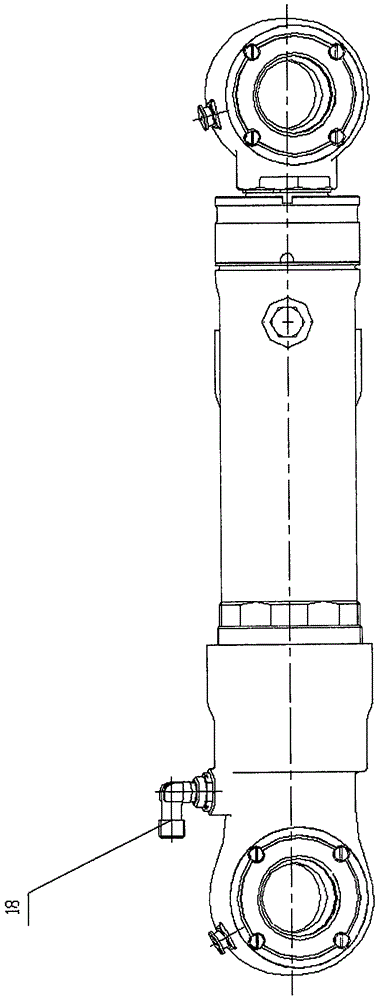

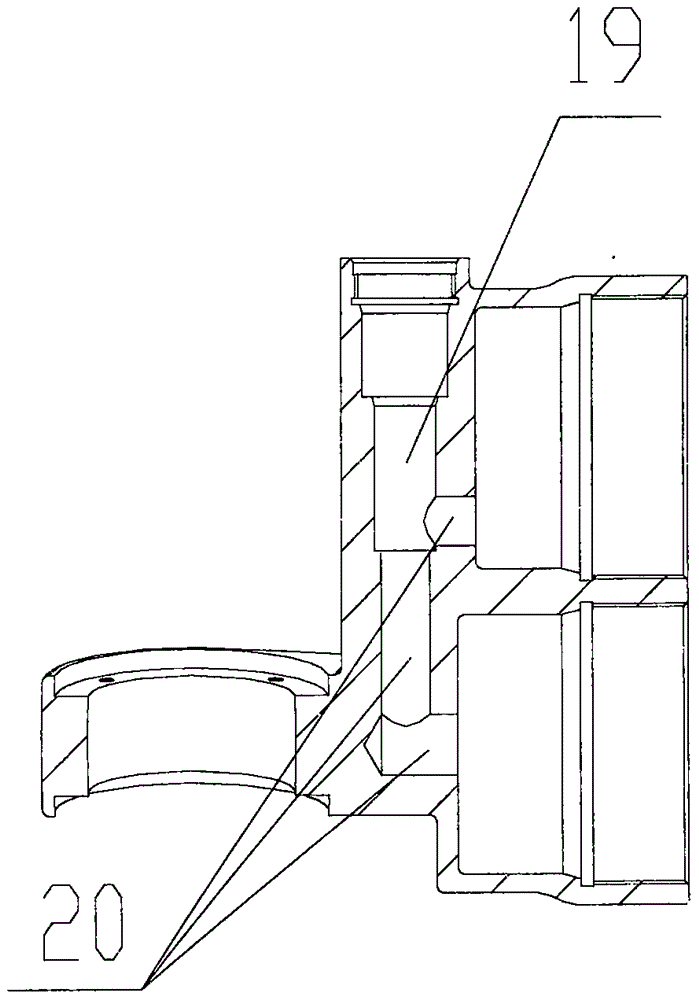

[0019] like figure 1 , 2 , 3, and 4 show a double-tube oil-gas spring, which includes a connecting body 1, a damping valve 2, an adjustment pad 3, an oil cylinder 4, a main piston 5, an oil cylinder interface 6, a guide sleeve 7, a sealing cover 8, a lower Pin lug 9, inflation valve 10, air chamber cover 11, cylinder 12, floating piston 13, locking valve 14, small piston 15, locking interface 16 and joint bearing 17, and nitrogen is used as the elastic medium.

[0020] Joint body 1, lower pin lug 9 are equipped with joint bearing 17, link to each other with car body attached seat by joint bearing 17. The joint bearing 17 can effectively eliminate the lateral force on the spring caused by installation errors. The oil cylinder 4 is connected with the connecting body 1 through threads, and the main piston 5 adopts two combined sealing forms to cooperate with the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com