Construction method for mounting front-end capillary tube heat exchanger of subway tunnel heat pump

A technology of capillary tube and heat exchanger, which is applied in the field of installation and construction method of capillary tube heat exchanger at the front end of subway tunnel heat pump, which can solve problems such as lack of construction experience and capillary tube construction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, functions and effects realized by the present invention easy to understand, the present invention is further elaborated below.

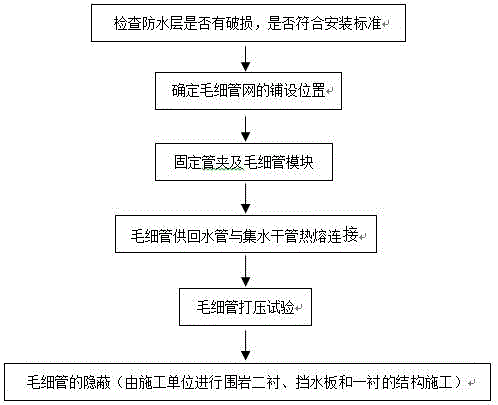

[0020] The installation and construction method of the capillary heat exchanger at the front end of the subway tunnel heat pump includes the following steps:

[0021] (1) Requirements before installation and construction of heat exchanger

[0022] The construction of the subway waterproof layer has been completed and meets the quality acceptance standards for waterproof construction.

[0023] (2) Capillary heat exchanger installation

[0024] Preparations before installation:

[0025] 1. Before the equipment is installed, draw the installation reference line and positioning reference mark on the waterproof layer according to the requirements of the design drawings and technical documents.

[0026] 2. Check the position of the nozzle of the equipment again, and make a mark for installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com