Clamp for tensile strength test of material

A technique for tensile strength and testing, which is applied in the field of fixtures for holding specimens, and can solve the problems of unavoidable failure of the tensile test at the end of the specimen, unsatisfactory axial tension of the specimen, and extrusion failure of the end. , to increase the tensile test success rate, increase the test success rate, and achieve the effect of axial tensile failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

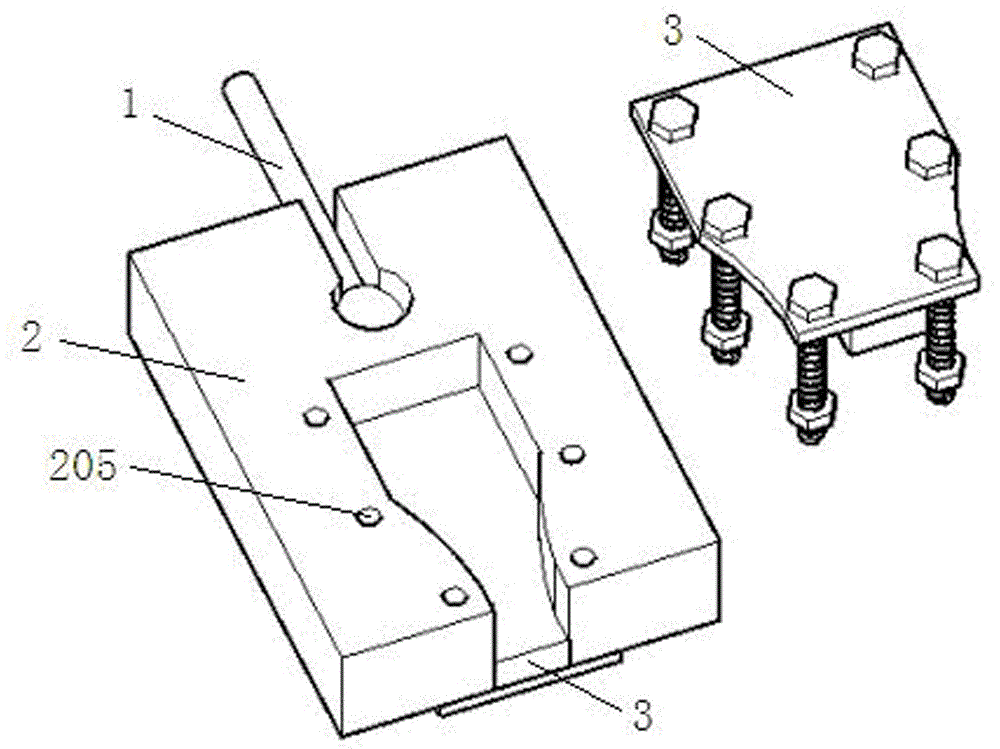

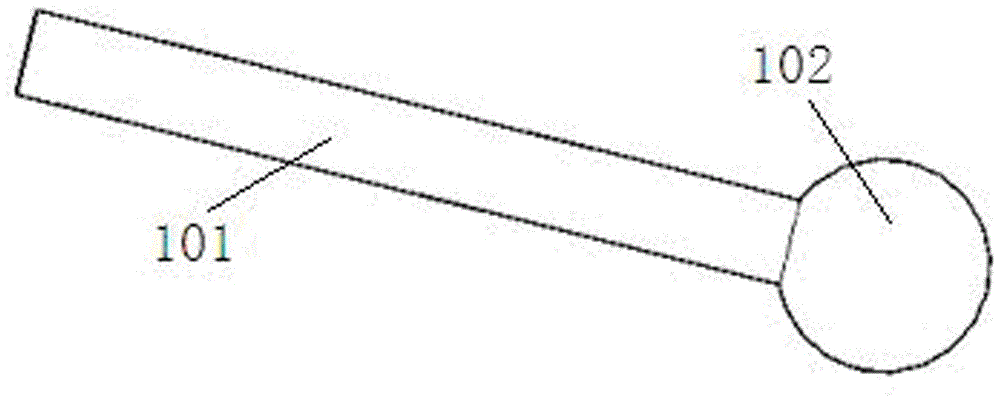

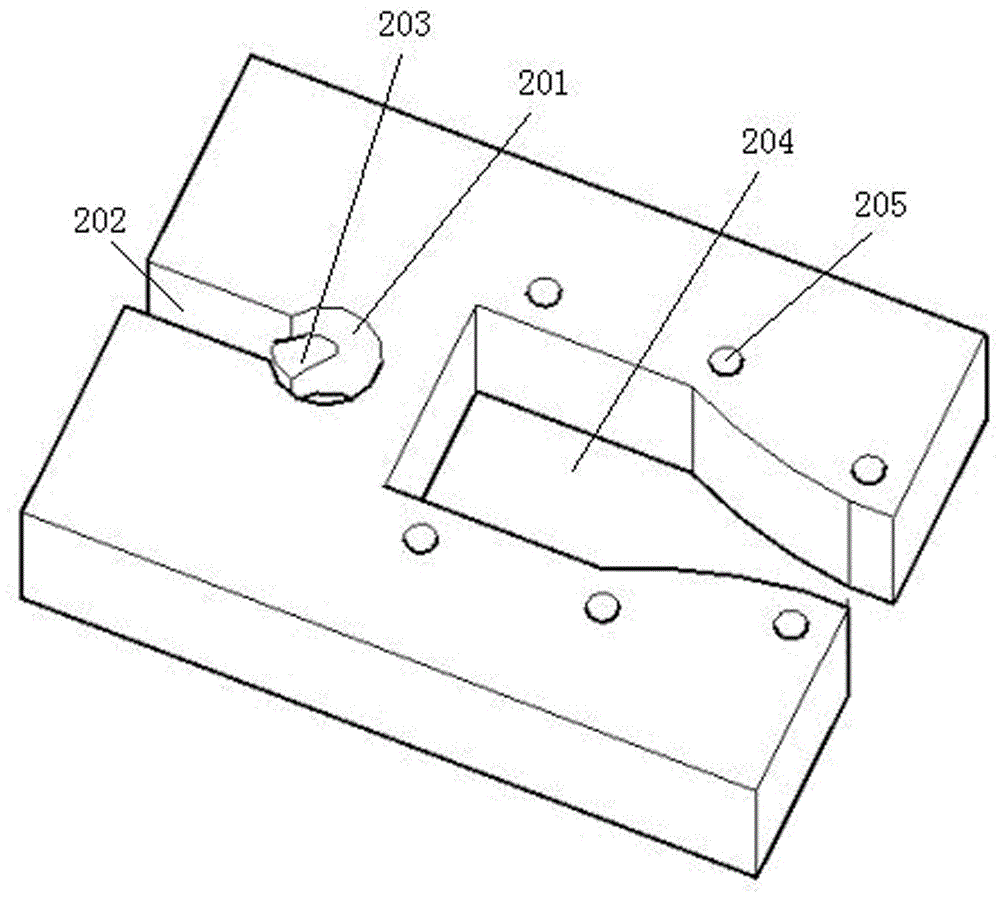

[0023] see figure 1 , This embodiment includes a pull rod 1 , a chuck 2 and a pressing device 3 . see figure 2 , the tie rod 1 includes a circular rod 101 , one end of the rod 101 is connected to the test device, and the other end of the rod 101 is affixed to a spherical end 102 . see image 3 , chuck 2 is a block component, from image 3 It can be seen from the figure that one side of the chuck 2 is provided with an open slot matching the shape of the pull rod 1, the open slot includes a cylindrical slot 201 with a diameter slightly larger than that of the spherical end 102, and the cylindrical slot 201 communicates with a bar-shaped open slot 202 , the width of the strip-shaped opening groove 202 is slightly larger than the diameter of the rod 101; a spherical groove 203 for fixing the spherical end 102 is provided at the middle positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com