Particle arching characteristic test device and test method thereof

A characteristic test and particle technology, which is applied in the direction of measuring device, monitoring particle agglomeration, particle and settlement analysis, etc., can solve the problems that it is difficult to consider the influence of soil arching effect, etc., and achieve the effect of strong repeatability, easy operation and reliable result data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

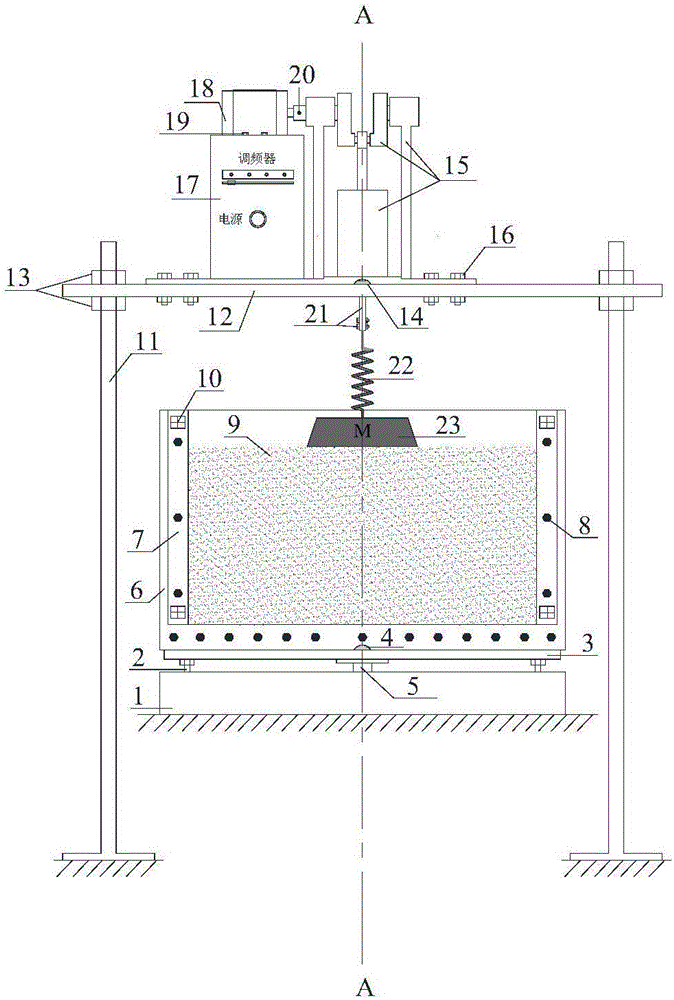

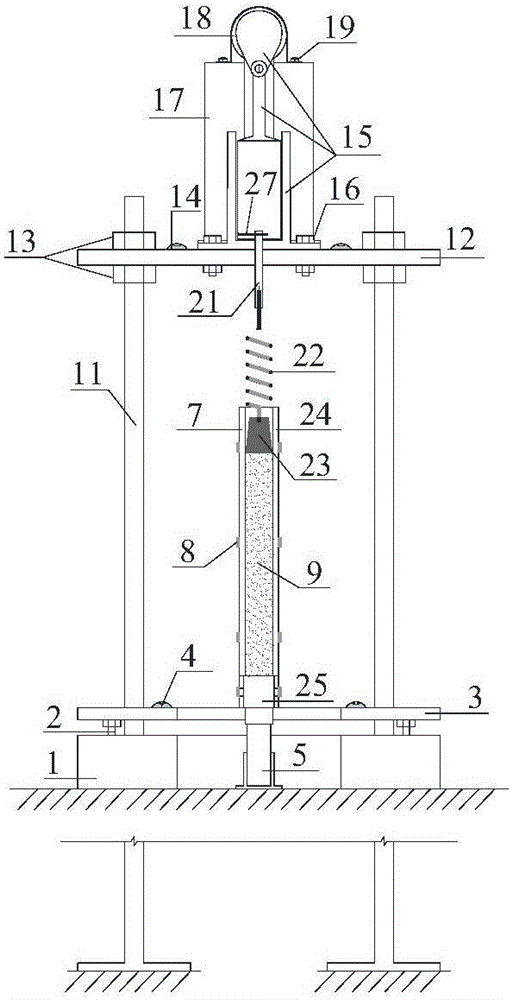

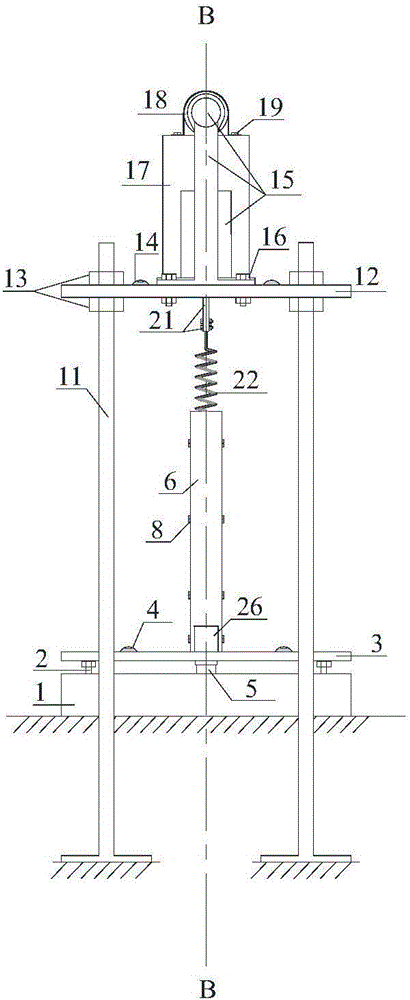

[0035] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0036] combine Figure 1 to Figure 6 As shown, the test device of the present invention includes a test platform mechanism, a model box mechanism, a particle sample and a loading mechanism. Apply a vertical dynamic load. Among them, specifically:

[0037] The test platform mechanism includes a base platform 1, bolts and nuts 2, a test top platform 3, a level bubble 4 and a stroke controller 5; the top platform 3 is connected to the base platform 1 through bolts and nuts 2, and the height of the adjustment nut 2 is adjustable. Seat platform; Stroke controller 5 is placed at the opening in the middle of the test platform mechanism.

[0038] The model box mechanism includes a U-shaped middle partition 6, a front perspective panel 7, and a rear perspective panel 24; the rear perspective panel 24 is connected with the U-shaped side frame middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com