F11.5 mm machinery passive type athermal lens

A passive, lens technology, applied in the direction of optical radiation measurement, instruments, measuring devices, etc., can solve the problems of image quality degradation, system focal length change, large temperature coefficient, etc., and achieve excellent image quality, good image quality, and high transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

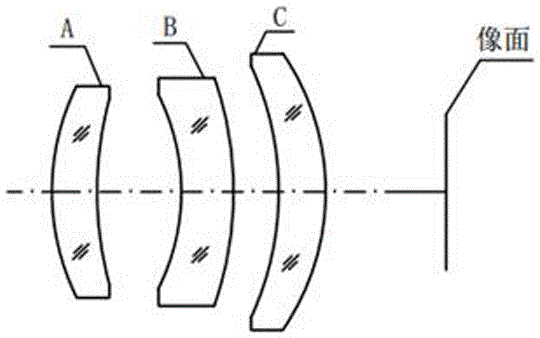

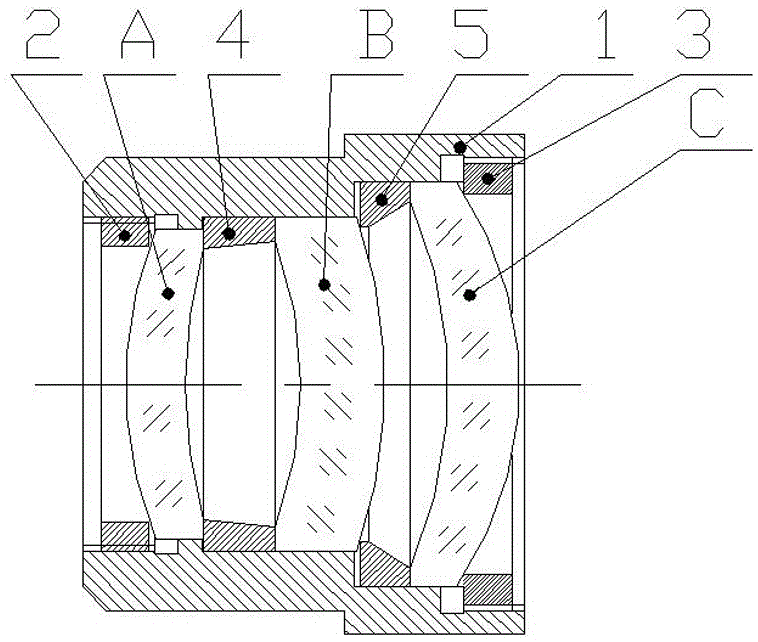

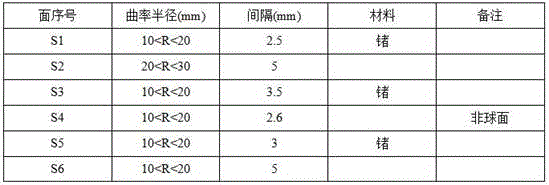

[0022] like Figure 1~2 As shown, a f11.5mm mechanically passive athermalized lens includes a positive lens A, a positive lens B, and a positive lens C arranged in sequence along the incident direction of light from left to right.

[0023] In the embodiment of the present invention, the air gap between the positive lens A and the positive lens B is 5 mm, and the air gap between the positive lens B and the positive lens C is 2.6 mm.

[0024] In the embodiment of the present invention, the positive lens A, the positive lens B, and the positive lens C are sequentially installed in the main lens barrel 1, the positive lens A is compressed by the A-plate pressure ring 2, and the positive lens C is pressed by the C The film pressing ring 3 is pressed tightly, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com