High-pressure-difference gas target device suitable for superhigh-intensity deuterium tritium fusion neutron source

A technology of fusion neutron and target device, which is applied in the direction of neutron source, etc., can solve the problems of melt-through, excessive heat flux density of target point, and massive release of tritium from neutron source damage, so as to reduce the cost of use and avoid the problem of heat bearing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

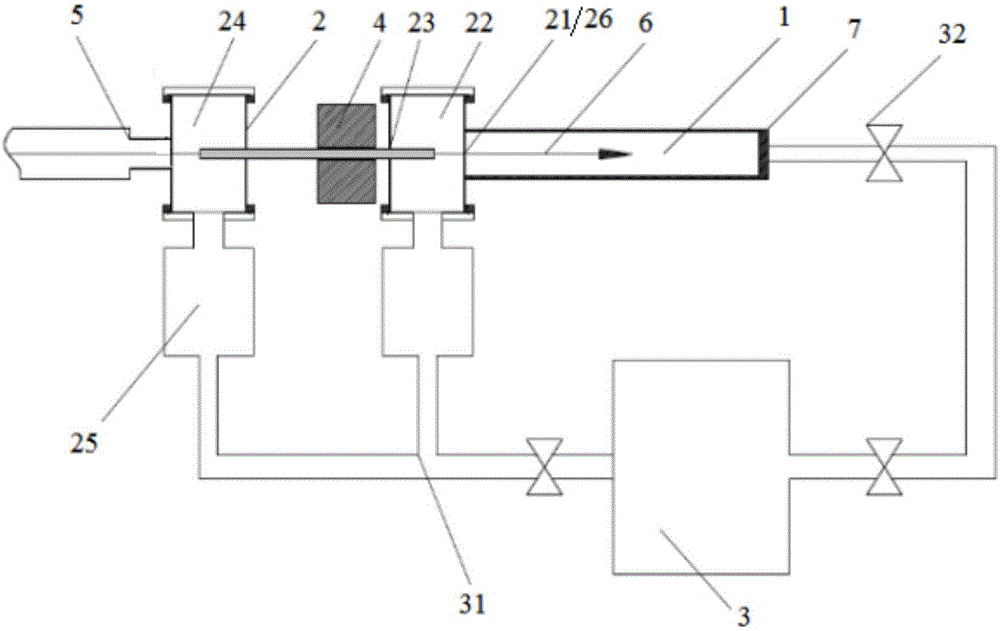

[0035] The invention can be used at the end of a strong current deuterium-tritium fusion neutron source to generate a strong current fusion neutron. The tritium gas or deuterium gas in the reaction gas chamber and the accelerator deuterium beam undergo fusion reaction. A major design feature of the structure of this device is that while achieving high-current and intense beam transmission, the end of the accelerator is realized through a vacuum differential system. -5 Pa to gaseous target reaction gas chamber 10 3 A total of 8 orders of pressure spanning of Pa, long-distance and low-loss transmission of high-strength deuterium beams in small-diameter pipes, and on-line purification, recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com