Segmented dotting and embossing welding strip, photovoltaic assembly and manufacturing method

A segmented, ribbon technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of reducing the power of battery components, reducing the absorption of light from the reflective surface of the ribbon, and the rise and fall of sawtooth segments and smooth segments. It is difficult to identify the starting position and other problems, so as to achieve the effect of improving absorption, maximizing power and high-efficiency welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] In order to achieve the purpose of the present invention, in some embodiments of a segmented dot embossed welding ribbon and its photovoltaic module and preparation method,

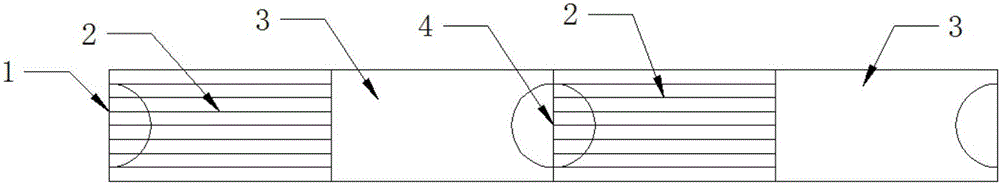

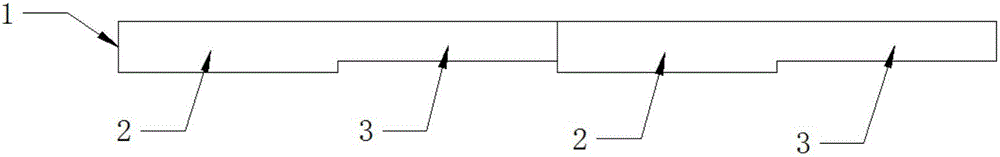

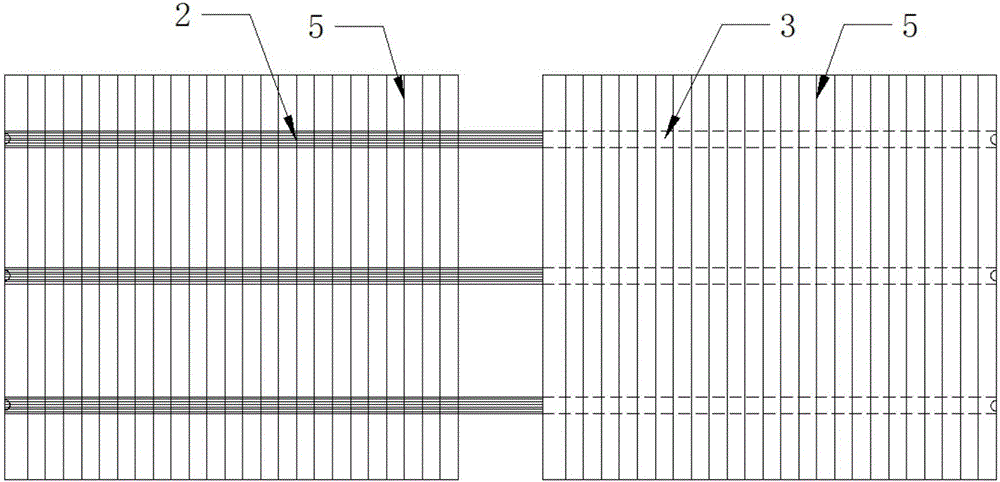

[0044] like Figure 1-4 As shown, the segmented embossed welding ribbon is provided with a plurality of serrated surfaces 2 and a plurality of smooth surfaces 3 on the surface of the welded ribbon 1, and the smooth surfaces 3 and the serrated surfaces 2 are arranged alternately. A circular concave point 4 is provided at the starting end of the serrated surface 2 , half of the circular concave point 4 is set at the starting end of the serrated surface 2 , and half is set at the ending end of the smooth surface 3 . The dimples 4 can also be in other shapes, and there is no specific requirement that the diameter of the dimples range between 0.1-1.3 mm. The racks of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com