Electric drives and electric equipment

A technology for electric drive and electric equipment, which is used in motor control, AC motor control, estimation/correction of motor parameters, etc. Guarantee, poor current sharing effect, etc., to avoid the waste of human and financial resources, break monopoly and blockade, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0030] The electric driving device 10 is installed in electric equipment such as electric tools, quadcopters, electric vehicles, electric boats, industrial electric forklifts, and electric military equipment, and is used to drive the electric equipment.

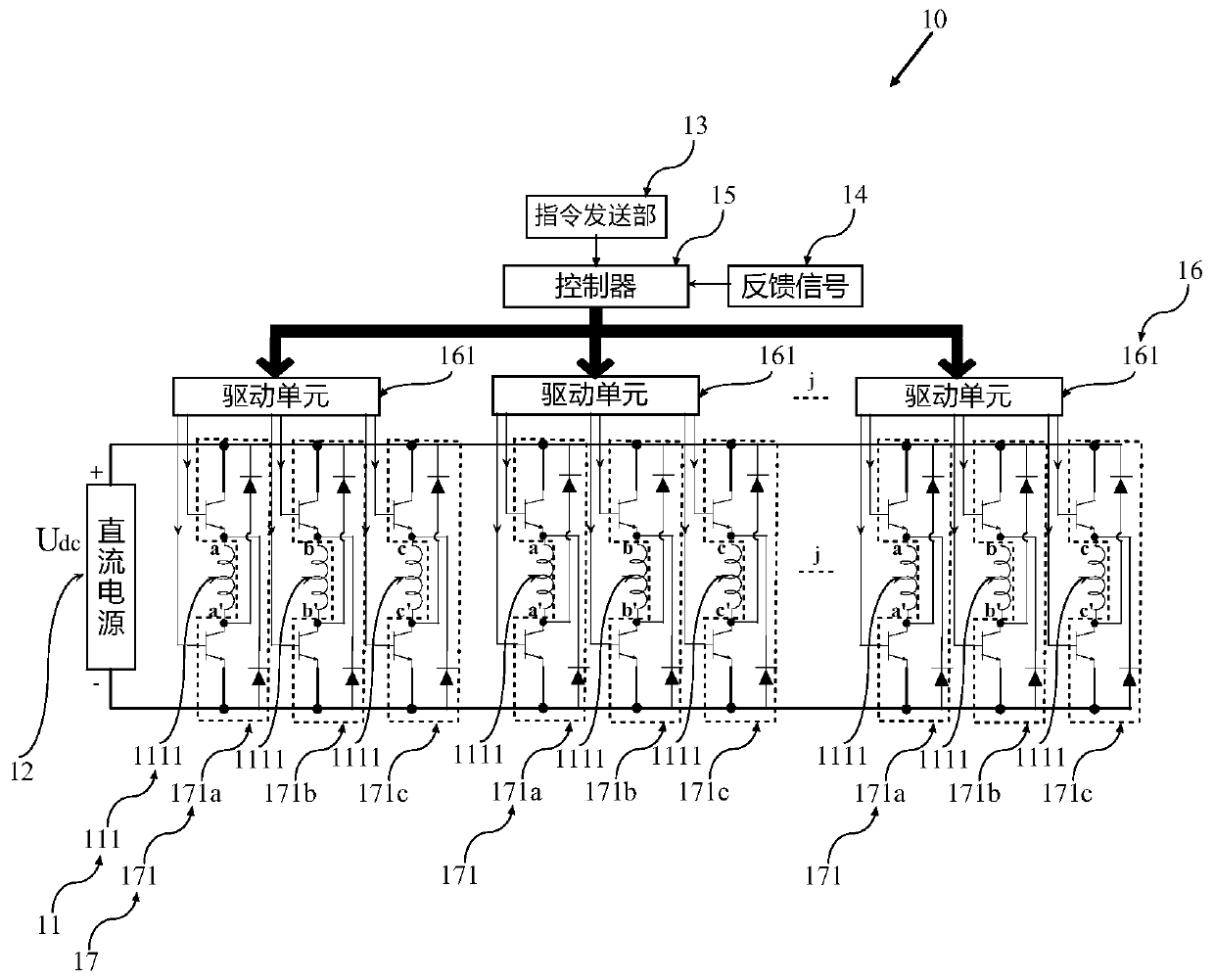

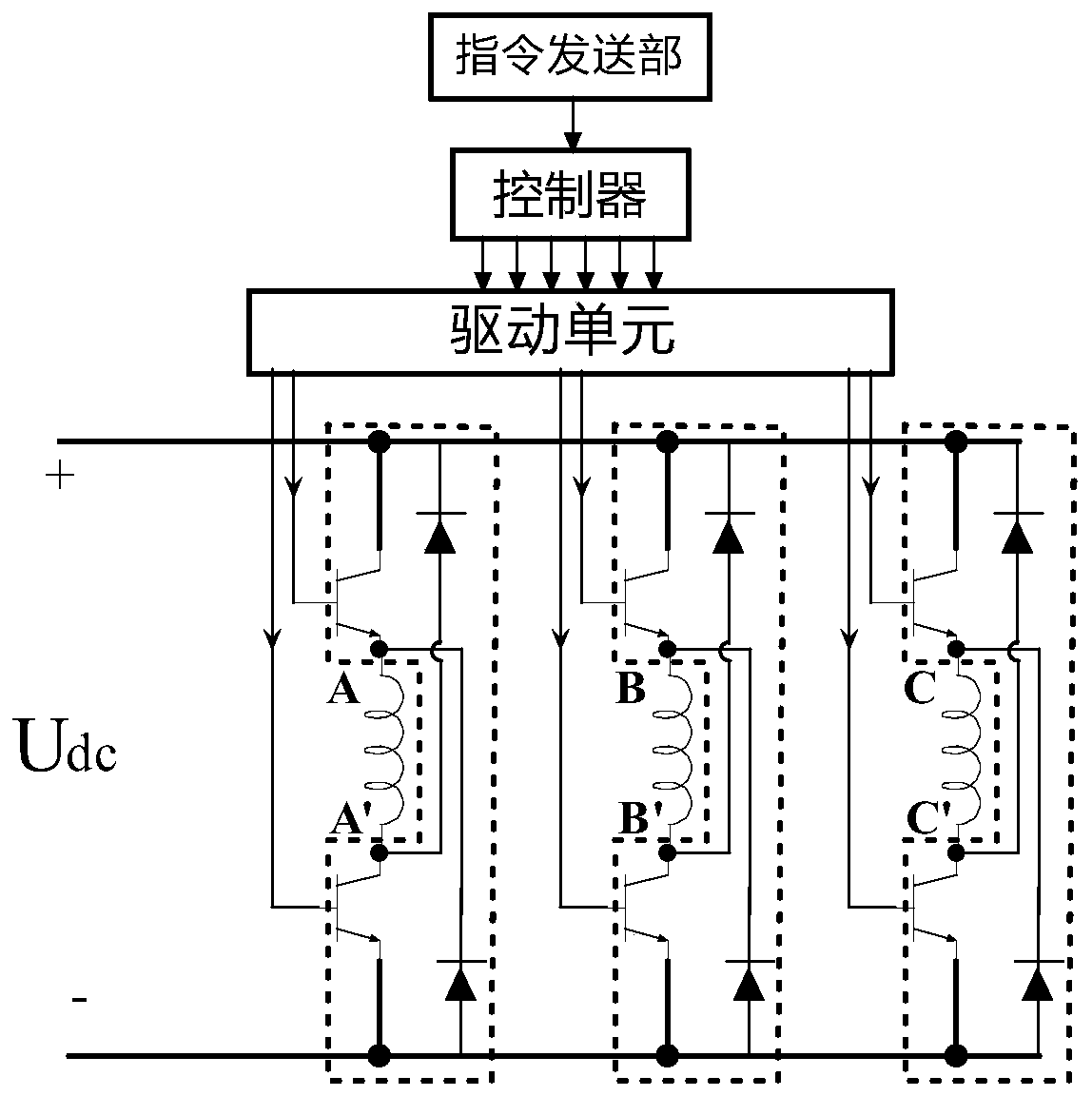

[0031] figure 1 is a schematic diagram of the circuit structure of the electric drive device in this embodiment.

[0032] like figure 1 As shown, the electric driving device 10 includes a switched reluctance motor 11 , a DC power supply 12 , a command sending unit 13 , a feedback signal 14 , a controller 15 , a driver 16 and a power converter 17 .

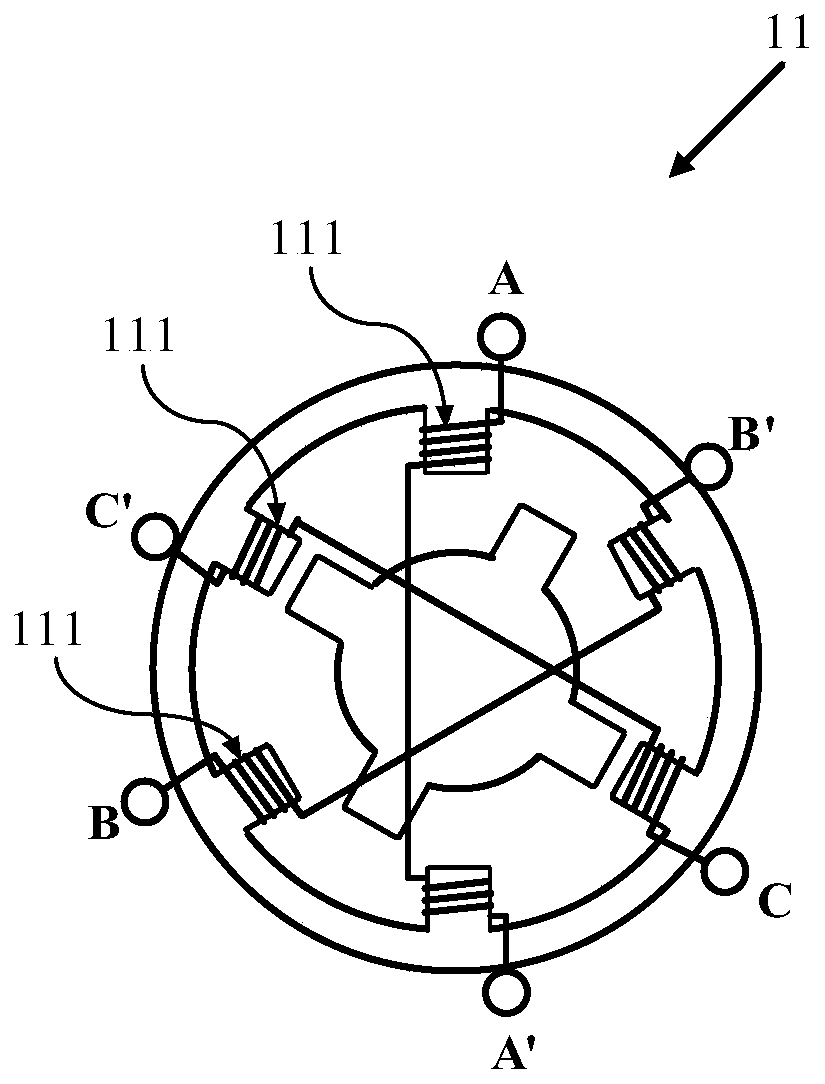

[0033] The switched reluctance motor 11 has a set of motor windings, the number of phases of the motor windings is k, a rated line voltage and a rated line current. The motor winding has j mutually independent polyphase winding units 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com