Multiphase alternating-current motor, inverter, electric driving component and electric actuator

A technology of AC motors and electric devices, applied in the direction of AC motor control, motors, electrical components, etc., can solve the problems of increasing the difficulty and cost of production and maintenance, and achieve the requirements of avoiding manpower and financial resources and reducing performance consistency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

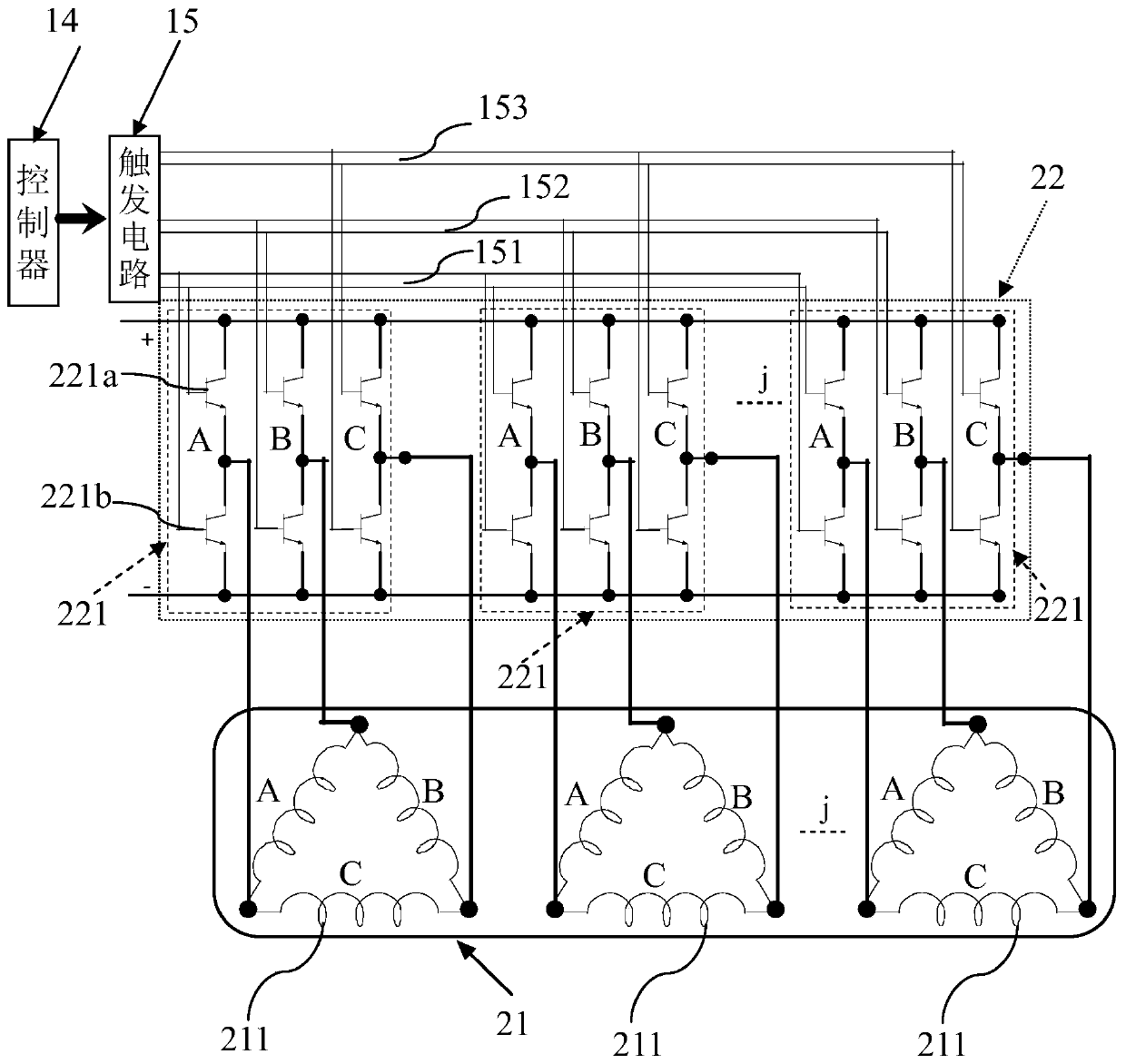

[0036] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

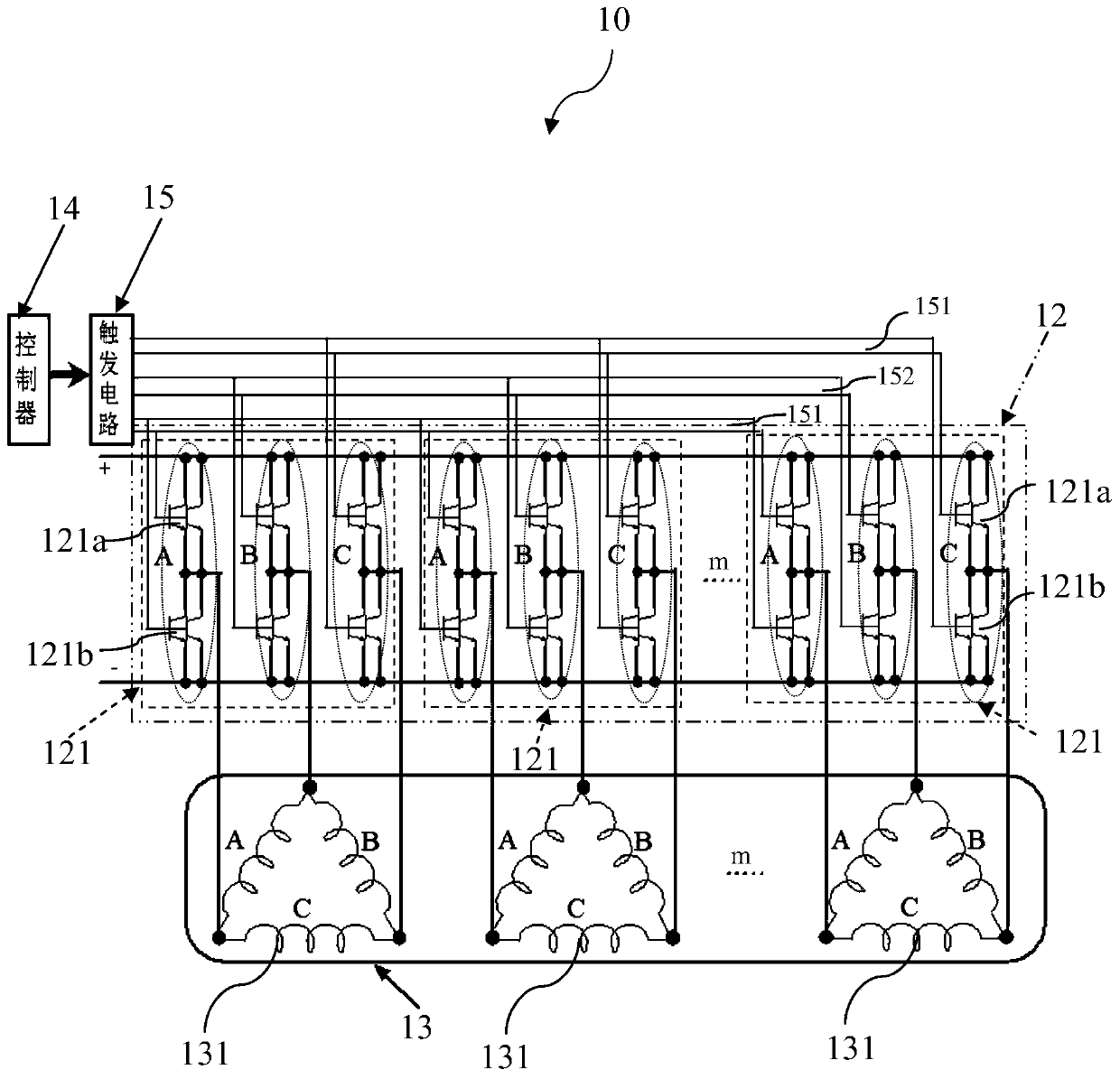

[0037] figure 1 It is a schematic diagram of the circuit structure of the electric drive assembly in this embodiment.

[0038] The electric driving assembly 10 is arranged in electric devices such as electric tools, quadcopters, electric vehicles, electric ships, industrial electric forklifts, and electric military equipment, and is used to drive the electric devices. like figure 1 As shown, the electric drive assembly 10 includes a DC power supply, an inverter 12 , a multi-phase AC motor 13 , a controller 14 and a trigger circuit 15 .

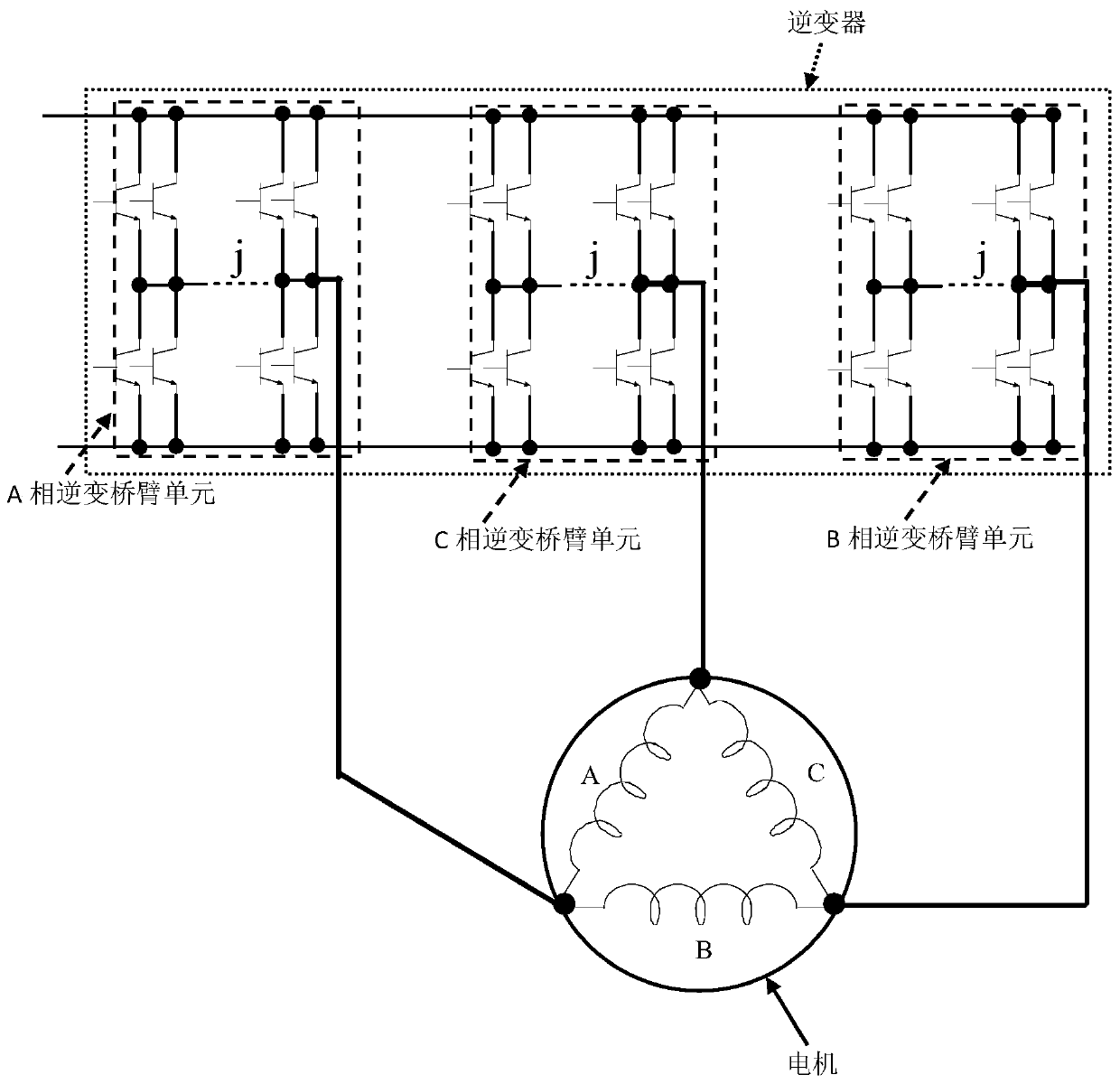

[0039] The DC power supply provides DC power to the inverter 12 ; the inverter 12 converts the DC power into AC power and supplies it to the multi-phase AC motor 13 according to the control signal sent by the controller 14 through the trigger circuit 15 . In this embodiment, the DC power source is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com