Electric drives and electric equipment

A technology of electric drive and electric equipment, applied in the direction of motor control, excitation or armature current control, electrical components, etc., can solve problems such as chopper failure, electric equipment failure, safety accidents, etc., to avoid human and financial consumption , the effect of reducing the requirements for performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments illustrate the DC electric drive device and electric equipment of the present invention in detail with reference to the accompanying drawings.

[0027] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0028] The electric driving device 10 is installed in electric equipment such as electric tools, quadcopters, electric vehicles, electric boats, industrial electric forklifts, and electric military equipment, and is used to drive the electric equipment.

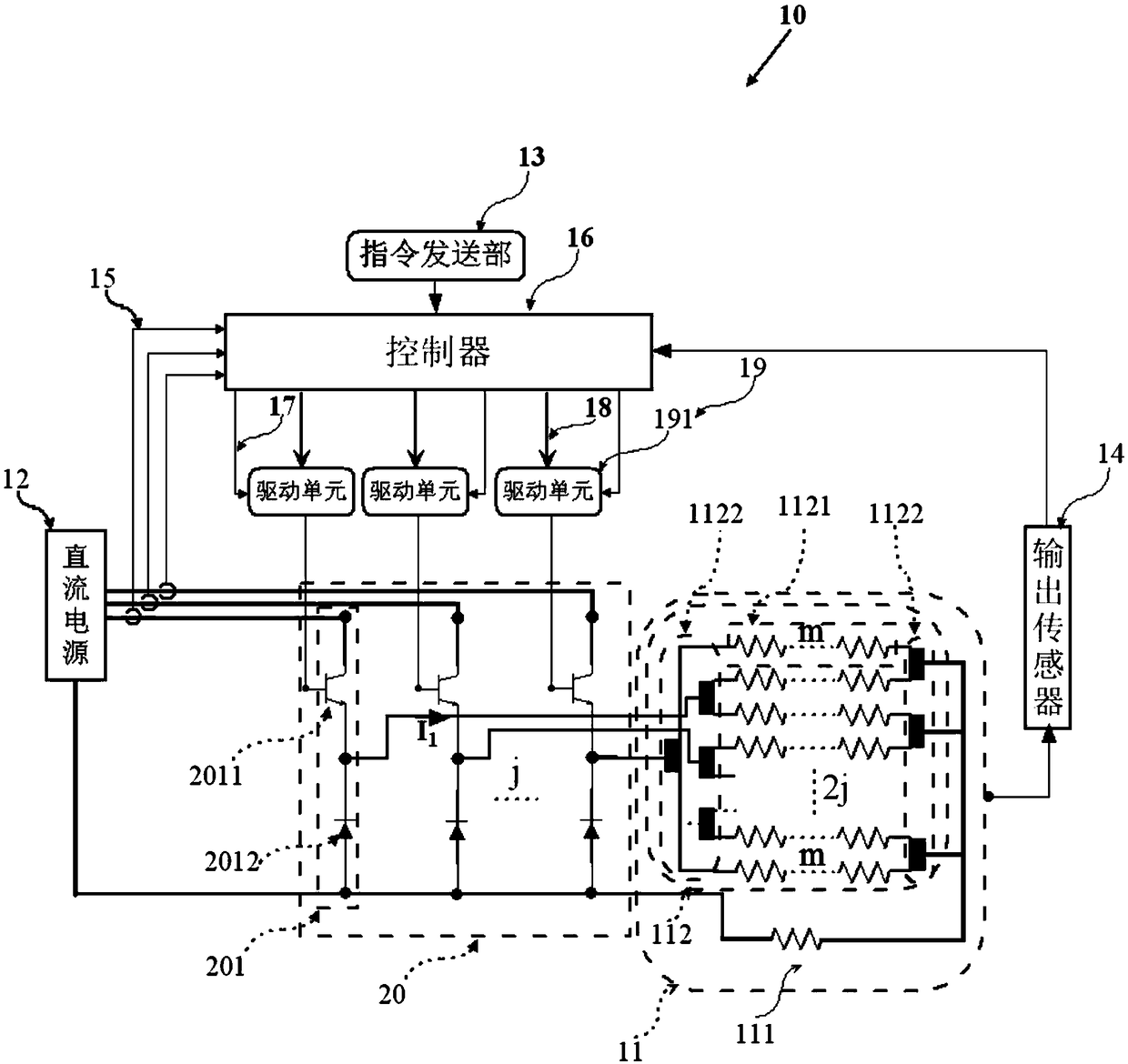

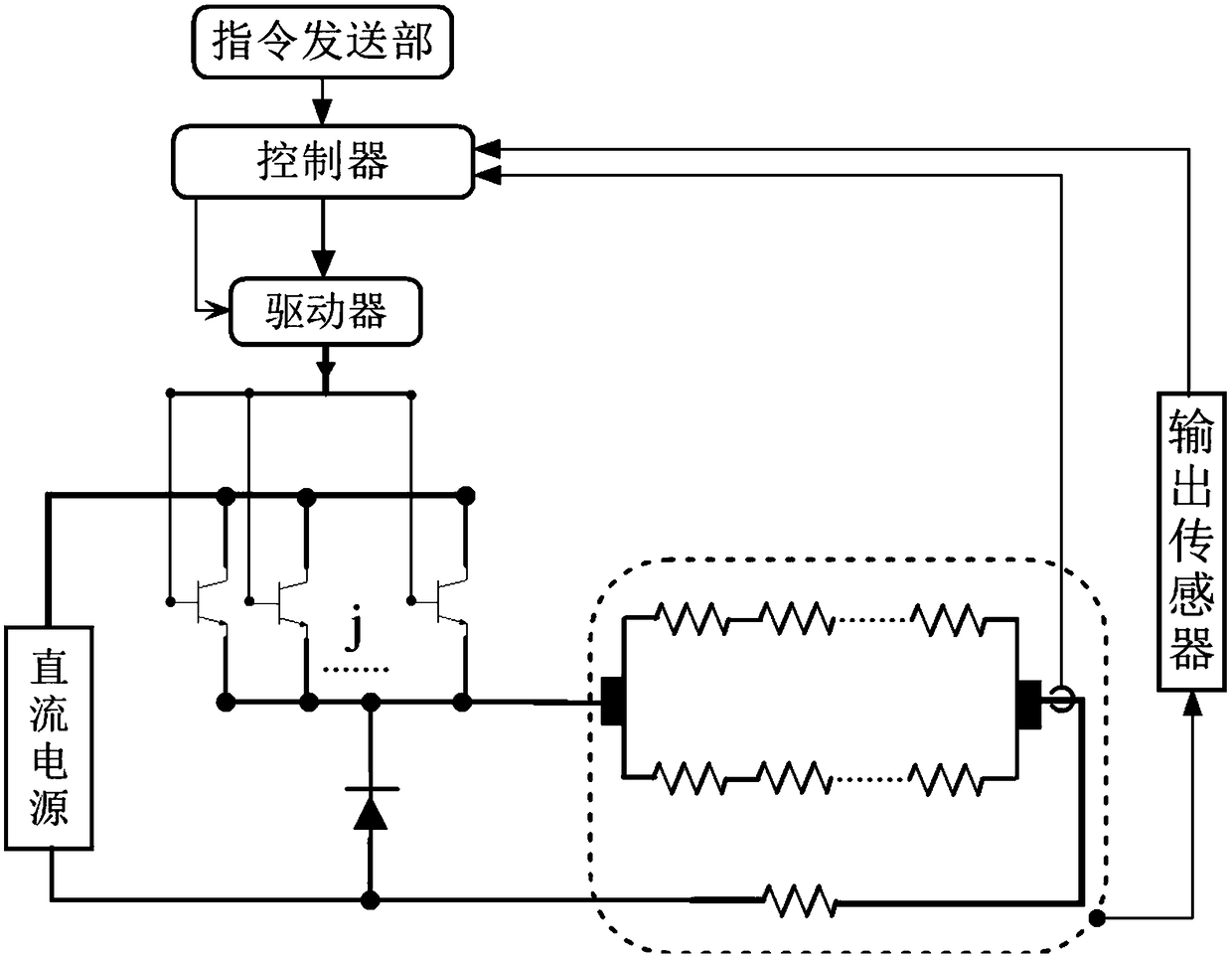

[0029] figure 1 It is a schematic diagram of the circuit structure of the DC electric drive device in this embodiment.

[0030] Such as figure 1 As shown, the electric driving device 10 includes a DC motor 11 , a DC power supply 12 , a command sending unit 13 , an output sensor 14 , a current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com