Heating pipe automatic processing device

An automatic processing and heating tube technology, applied in the direction of electric heating device, ohmic resistance heating, heating element shape, etc., can solve the problem of broken resistance wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the technical solution of the present invention will be described in detail through specific examples.

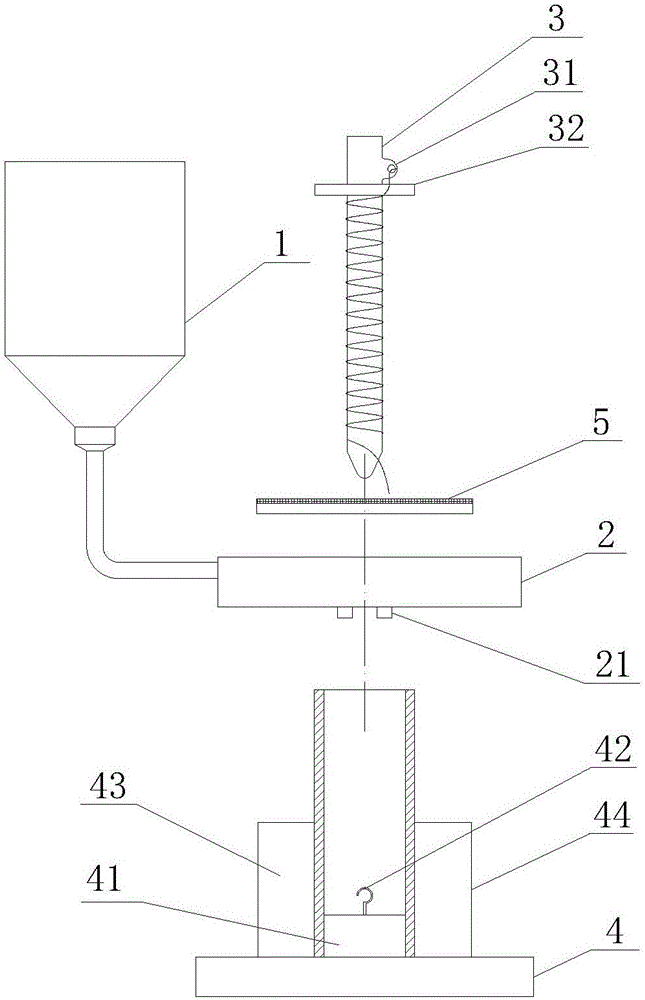

[0025] like figure 1 as shown, figure 1 It is a structural schematic diagram of a heating tube automatic processing device proposed by the present invention.

[0026] refer to figure 1 , an automatic heating tube processing device proposed by the embodiment of the present invention, comprising: a frame and a powder adding container 1 installed on the frame, a powder injection box 2, a lead bar 3, a support seat 4, a first driving mechanism, a second The second driving mechanism and the third driving mechanism, wherein:

[0027] The powder filling container 1 is used to inject filler powder into the powder injection box 2; the powder injection box 2 is provided with a guide hole through both ends, and the inside of the powder injection box 2 is provided with a ring cavity arranged in a ring around the guide hole. The lower end of 2 is provided with a powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com