Spiral mill type ditching straw deep-burying chopper

A technology of spiral milling cutter and straw, which is applied in the direction of harvesters, agricultural machinery and implements, shovels, etc., can solve the problems of deep burial of straw, soil moisture, and seeds that cannot germinate normally, so as to prevent burning, reduce consumption, The effect of enhancing soil organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

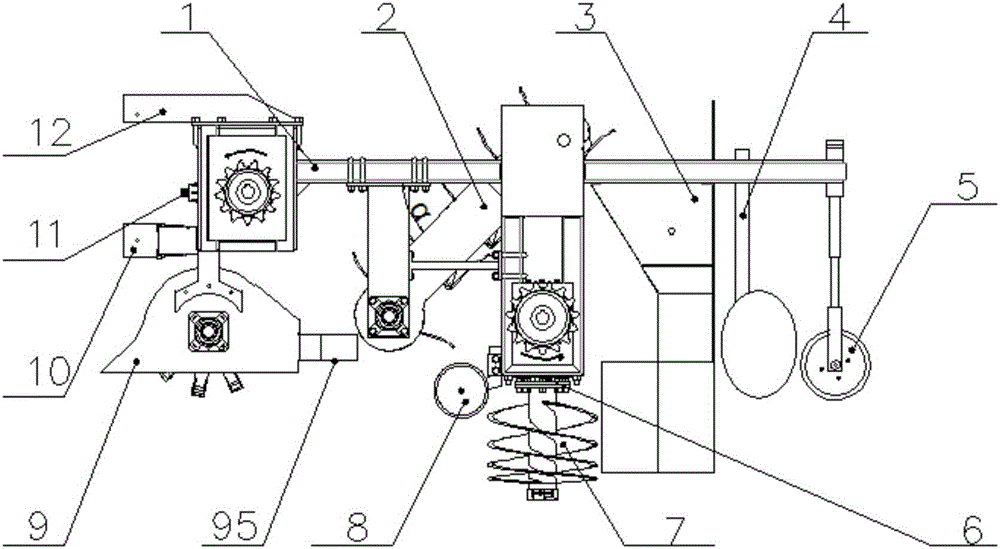

[0046] Example: such as figure 1 As shown, a spiral milling cutter type straw deep burying machine of the present invention includes a frame 1, a front transmission box 11, a rear transmission box 6, a transmission device, and is installed on the frame 1 from the working front end to the rear end. The stubble removal device 9, the conveying device 2, the disc ditching device 8, the spiral milling cutter ditching device 7, the blanking device 3 and the soil covering device 4 are arranged in sequence;

[0047] The working front end of the frame 1 is respectively connected to the upper suspension 12, the lower suspension 10 and the front transmission box 11, and is connected to the power machine through the upper suspension 12 and the lower suspension 10;

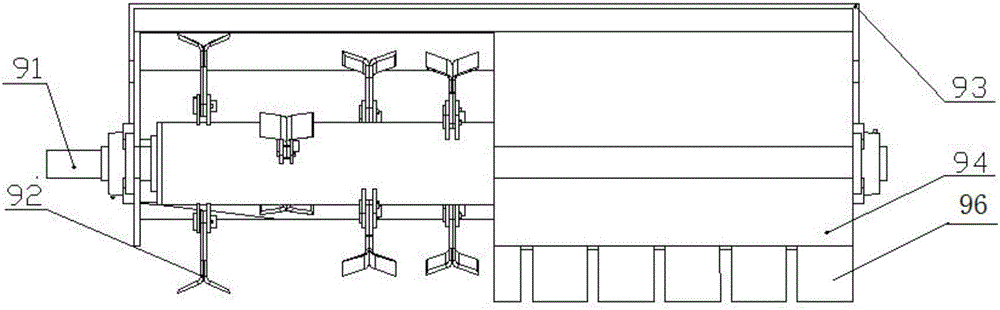

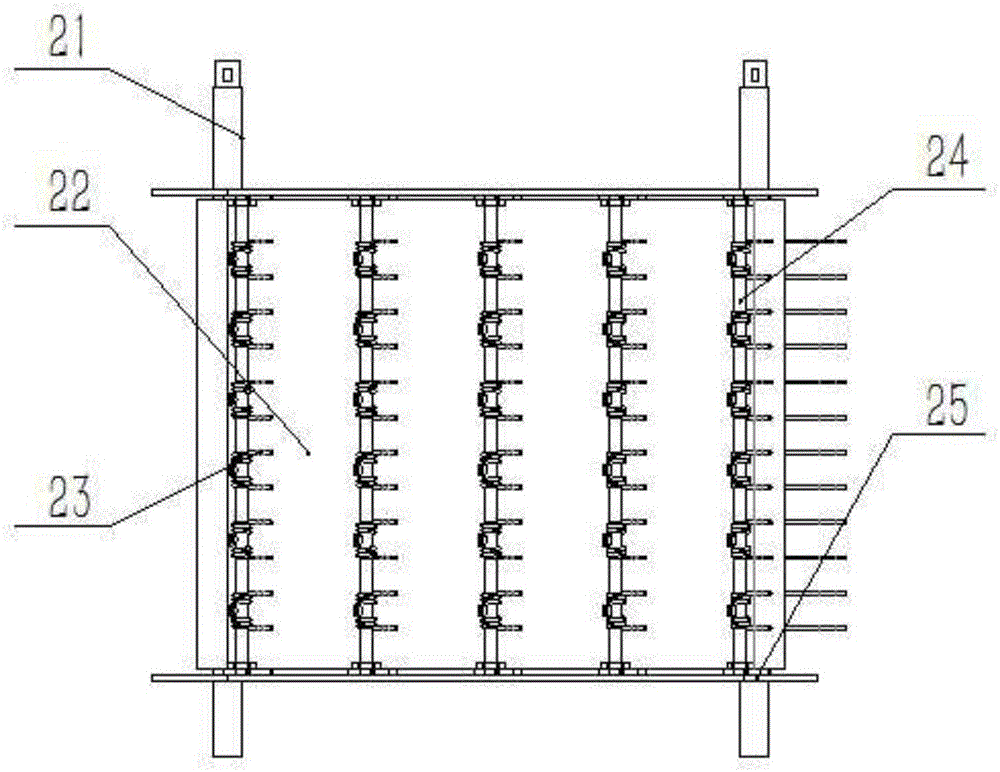

[0048] Such as figure 1 , figure 2 As shown, the stubble removal device 9 is connected to the front end of the frame 1 through its upper fixing frame, the stubble removal shaft 91 is connected to the power output shaft of t...

Embodiment 2

[0063] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the inclination angle α at which the conveying device 2 described in this embodiment is installed on the frame 1 is 40°.

Embodiment 3

[0064] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the inclination angle α at which the conveying device 2 described in this embodiment is installed on the frame 1 is 60°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com