Hybrid linear lever multi-degree-of-freedom controllable lifting type fruit picker

A degree of freedom, lifting technology, applied in the mechanical field, can solve the problems of large rotational inertia of the multi-link mechanical arm working device, high requirements on the machining accuracy of the hydraulic system, and high maintenance costs, and achieves compact structure, large load capacity, and high maintenance. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

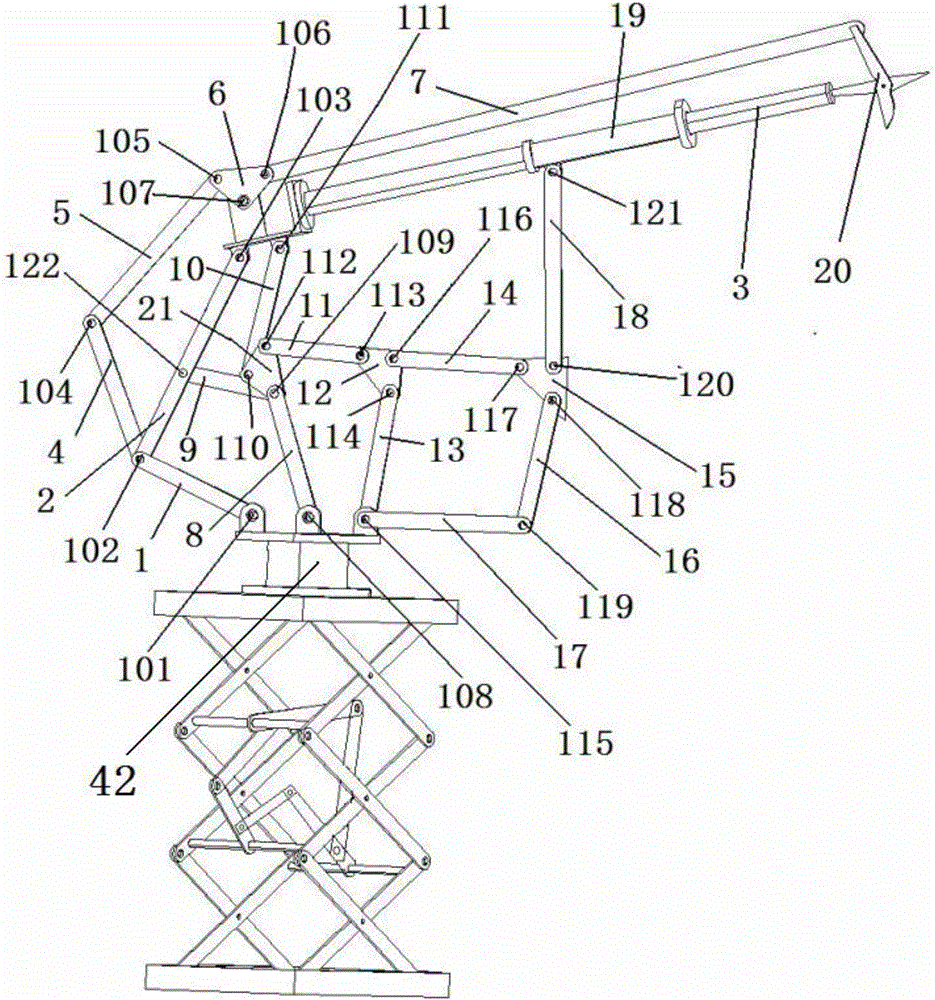

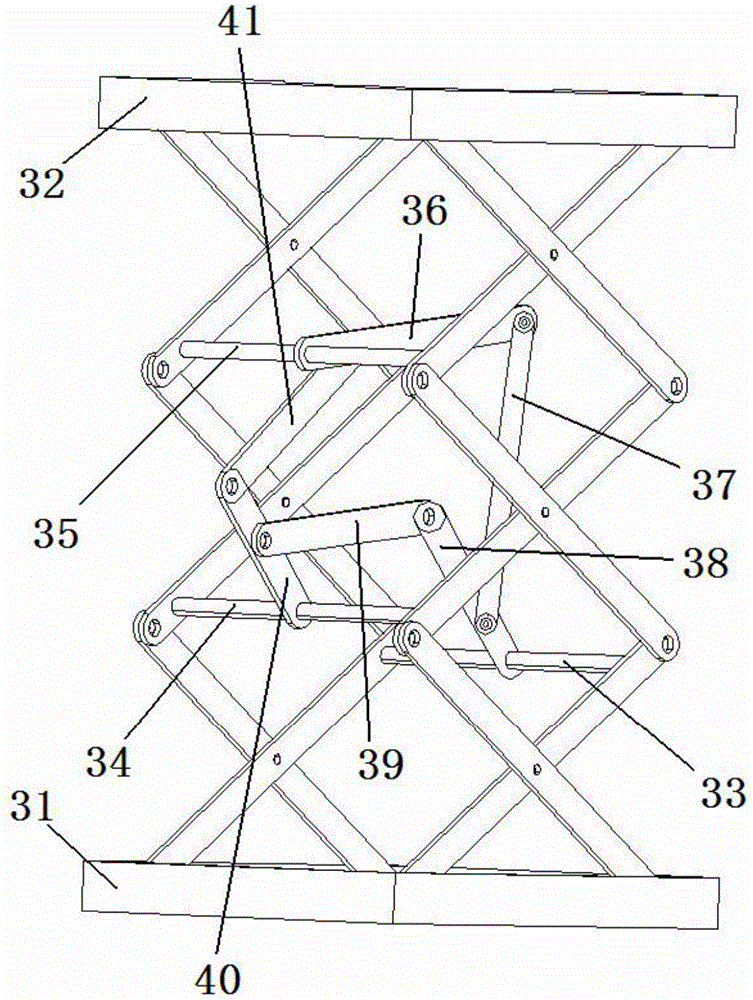

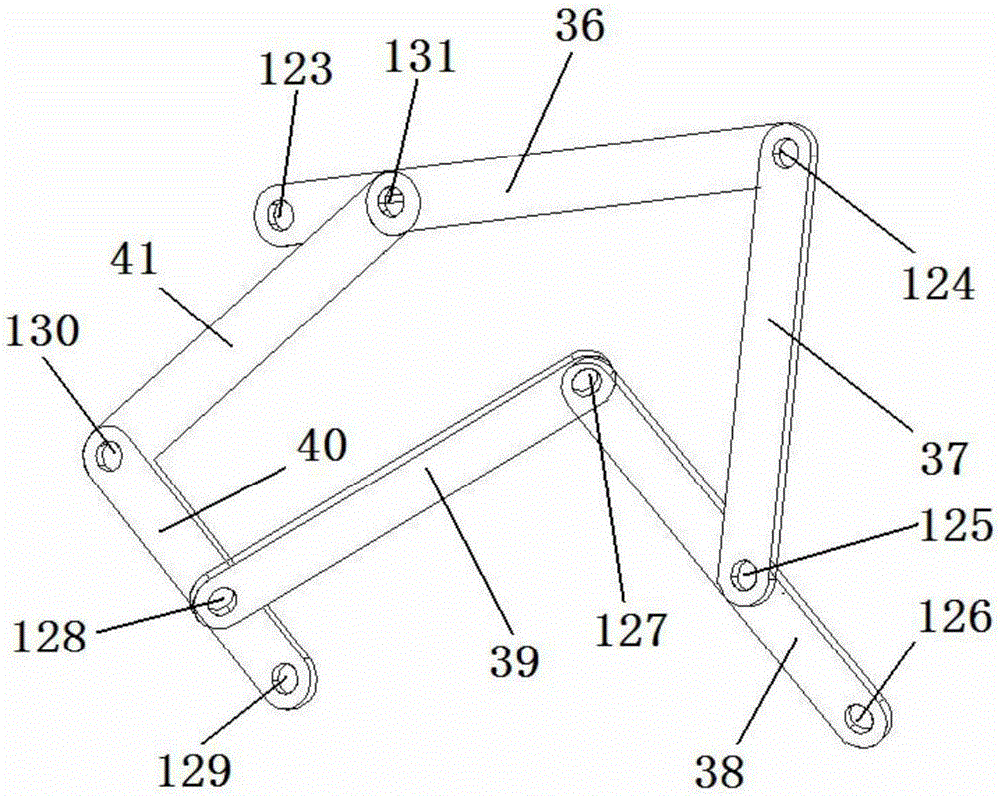

[0021] A hybrid linear lever multi-degree-of-freedom controllable lifting fruit picker, comprising a multi-link mechanical arm and a scissor-type hydraulic lifting platform,

[0022] The multi-link manipulator includes a frame 42, an execution terminal 20, a link 1, a link 2, a link 3, a link 4, a link 5, a link 7, a link 8, and a link 8. , connecting rod nine 9, connecting rod ten 10, connecting rod eleven 11, connecting rod thirteen 13, connecting rod fourteen 14, connecting rod sixteen 16, connecting rod seventeen 17, connecting rod eighteen 18 and sliding sleeve 19 ,

[0023] One end of the connecting rod 1 is connected to the frame 42 through the rotating pair 101, the other end of the connecting rod 1 is connected with one end of the connecting rod 2 through the rotating pair 2 102, and the other end of the connecting rod 2 is connected with the connecting rod through the rotating pair 3 103. One end of connecting rod 33 is connected to the execution terminal 20, the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com