Mascara cream and preparation method thereof

A technique of mascara and parts by weight, which is applied in the field of cosmetics, can solve the problems of difficulty in moisturizing makeup and easy moisturizing of mascara, and achieves the effect of good waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: a kind of mascara is prepared through the following steps:

[0067] S1, fully mixing deionized water, polyvinylpyrrolidone, polyvinyl alcohol, butylene glycol, and hydroxyethyl cellulose in corresponding parts by weight, and heating to 80-85°C to form a water phase;

[0068] S2, the dextrin isostearate, carnauba wax, beeswax, stearic acid, PEG-40 stearate, cyclomethicone, surfactant of corresponding parts by weight are heated to 80-85°C, an oil phase is formed, wherein the surfactant is glyceryl stearate and PEG-100 stearate, and the ratio of the two parts by weight is 2:1;

[0069] S3, uniformly mix CI77499 in corresponding parts by weight with the oil phase obtained in step S2, and keep warm at 80-85°C to form a black oil phase;

[0070] S4, adding the black oil phase obtained in step S3 to the water phase obtained in step S1, homogenizing to form a water-oil mixture;

[0071] S5, defoaming the water-oil mixture obtained in step S4, and lowering the te...

Embodiment 2

[0074] Embodiment 2: a kind of mascara, the difference with embodiment 1 is, in step S6, add the preservative of corresponding weight parts, mix evenly, this preservative comprises the ratio of parts by weight of 1:1:1:2 Bis(hydroxymethyl)imidazolidinyl urea, iodopropynyl butylcarbamate, methylparaben, propylene glycol.

Embodiment 3

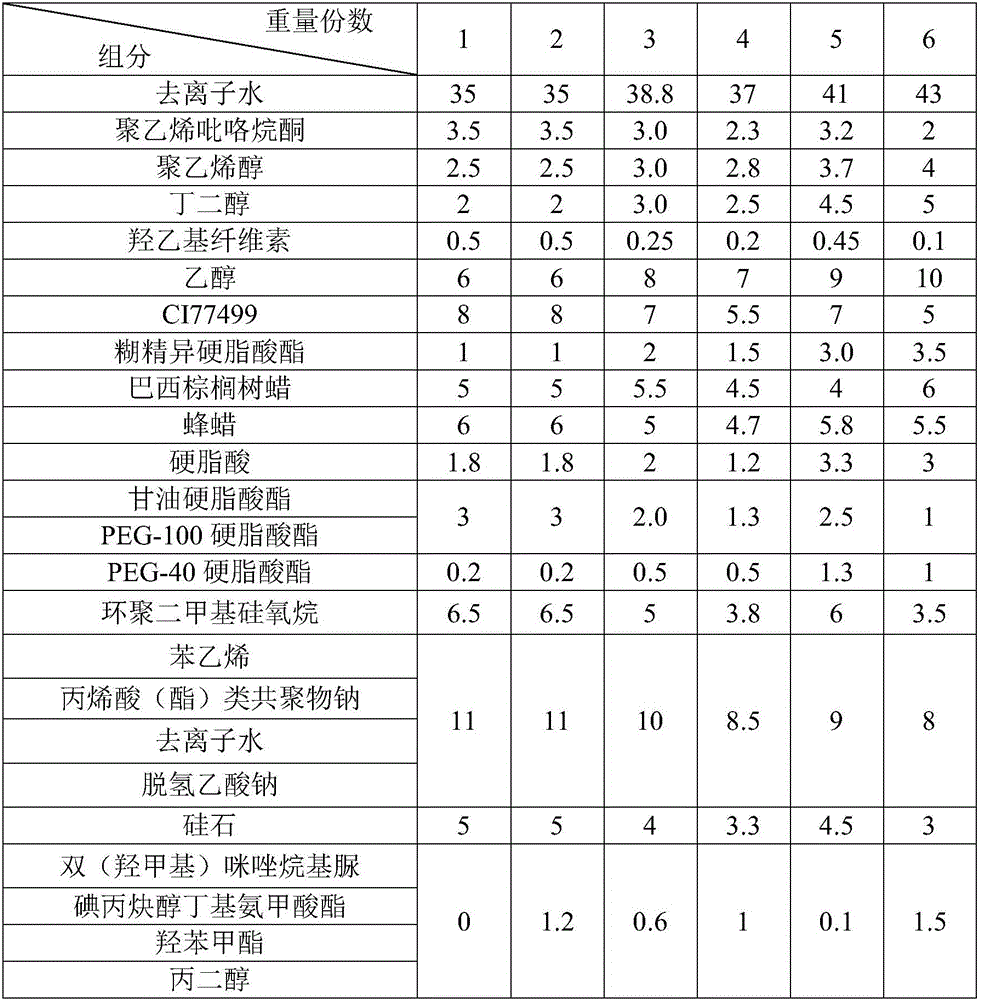

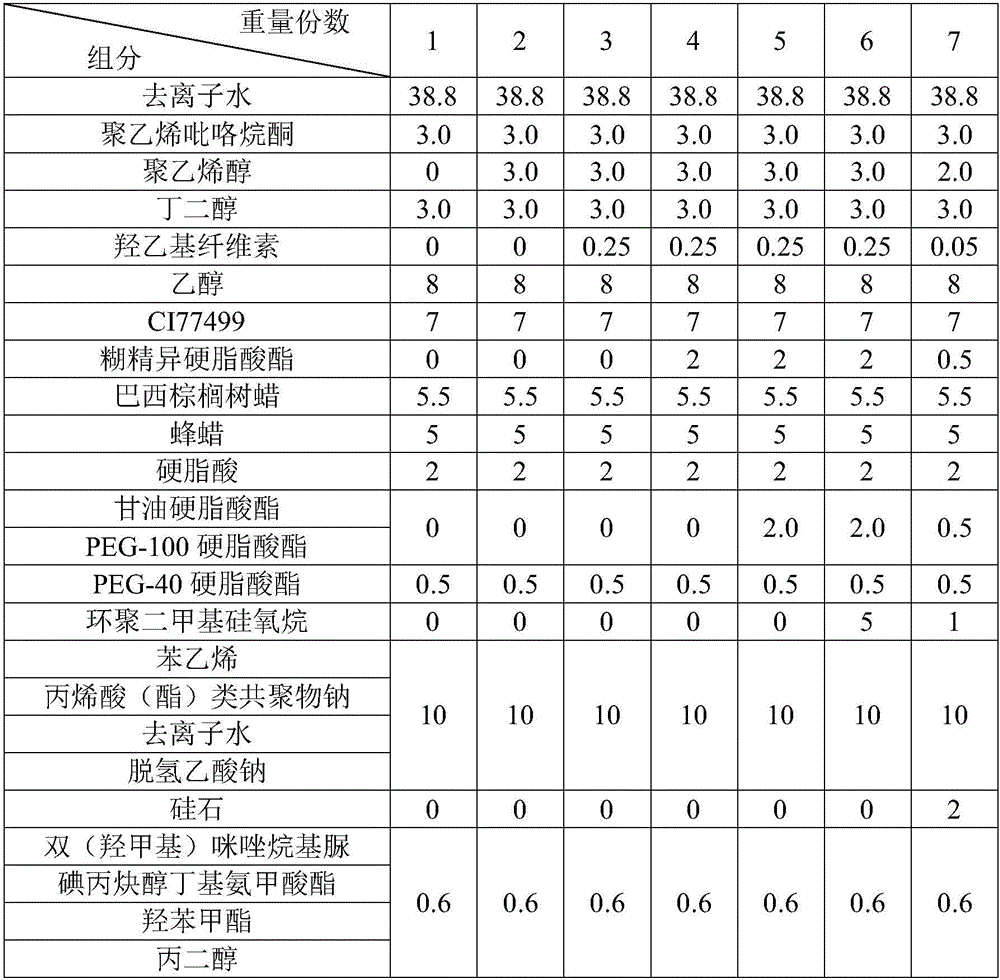

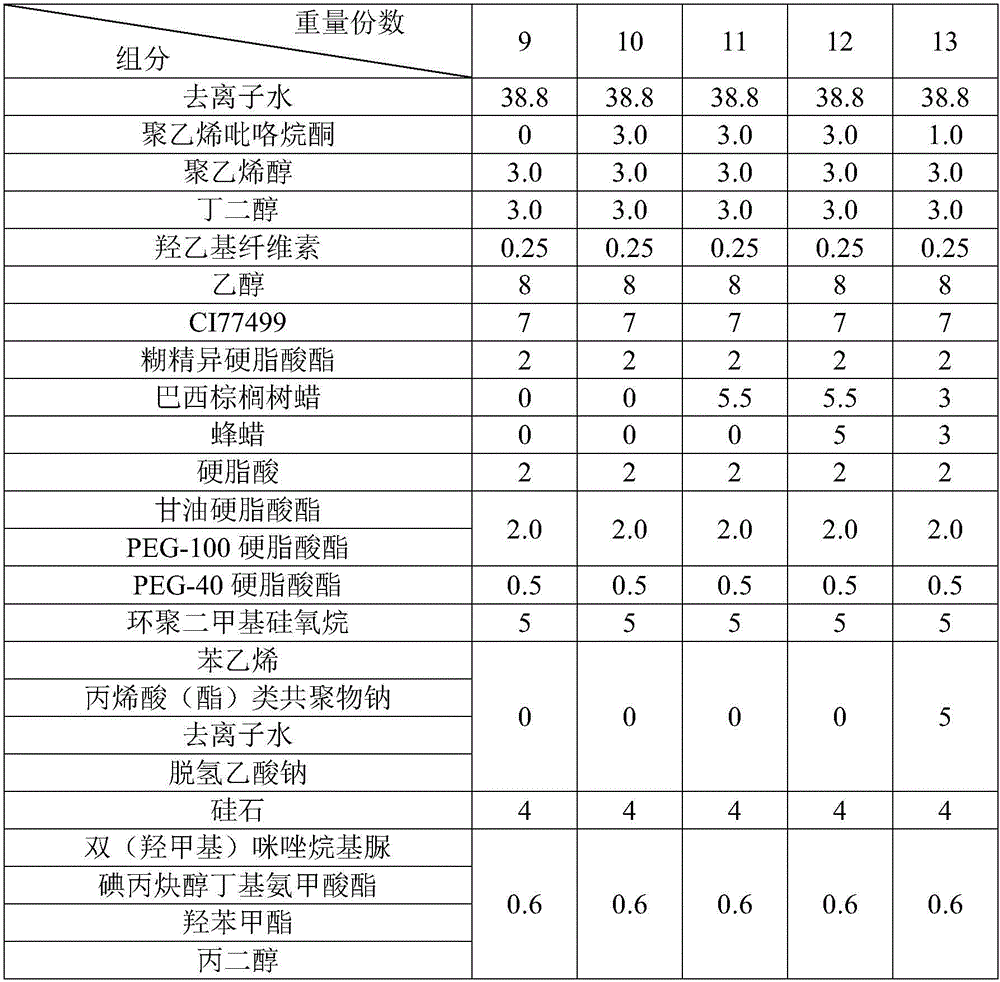

[0075] Embodiment 3: a kind of mascara, the difference with embodiment 2 is that each component and parts by weight thereof are as shown in table 1, wherein, in the film forming agent, styrene, acrylic acid (ester) copolymer sodium, The ratio of parts by weight of deionized water and sodium dehydroacetate is 1:4:1:2.5; in the surfactant, the ratio of parts by weight of glyceryl stearate and PEG-100 stearate is 3:1; The ratio of parts by weight of bis(hydroxymethyl) imidazolidinyl urea, iodopropynyl butylcarbamate, methylparaben and propylene glycol in the preservative is 1:1.5:1.5:2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com