Glycerine decolorization apparatus convenient to disassemble and assemble

A decolorization and glycerol technology, which is applied in ion exchange treatment devices, separation/purification of hydroxyl compounds, liquid separation of solid adsorbents, etc., can solve problems such as unfavorable replacement of activated carbon, incomplete decolorization of glycerol, and non-removable decolorization devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

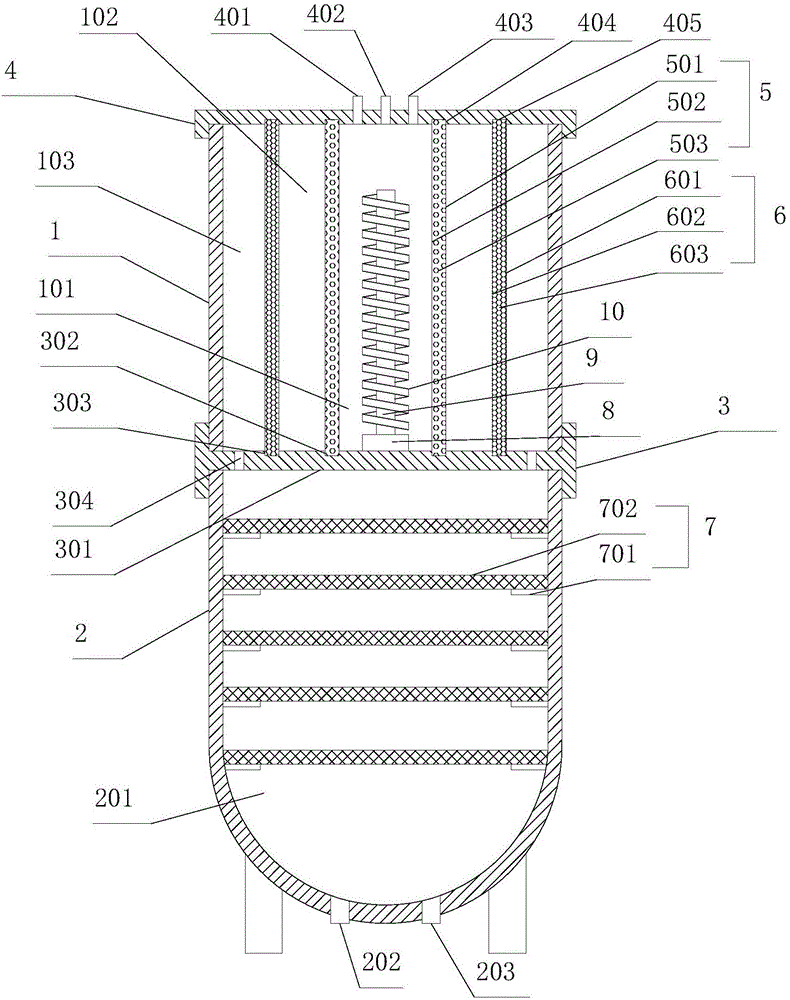

[0015] refer to figure 1 , the present invention proposes a kind of glycerol decolorization device that is convenient for disassembly and assembly, comprising a first decolorization cylinder 1, a second decolorization cylinder 2, a connecting cylinder 3, and a cylinder cover 4, wherein:

[0016] The first decolorizing cylinder 1 has a first chamber, the second decolorizing cylinder 2 has a second chamber 201, and the two ends of the connecting cylinder 3 are respectively detachably connected with the first decolorizing cylinder 1 and the second decolorizing cylinder 2. There is a partition 301, and the cylinder cover 4 is installed on the end of the first decolorization cylinder 1 away from the connection cylinder 3 and seals the first chamber.

[0017] The first chamber is provided with a first activated carbon filter element 5 and a second activated carbon filter element 6, the first activated carbon filter element 5 and the second activated carbon filter element 6 are cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com