A regenerable double-layer roll-up air filter

An air filter, roller shutter technology, applied in the field of renewable double-layer roller shutter air filters, can solve the problems of inability to remove odors and harmful gases, filtering effect and resistance fluctuations, etc., to achieve filtration efficiency and filter resistance. Stable, accurate pressure monitoring, prolonged use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

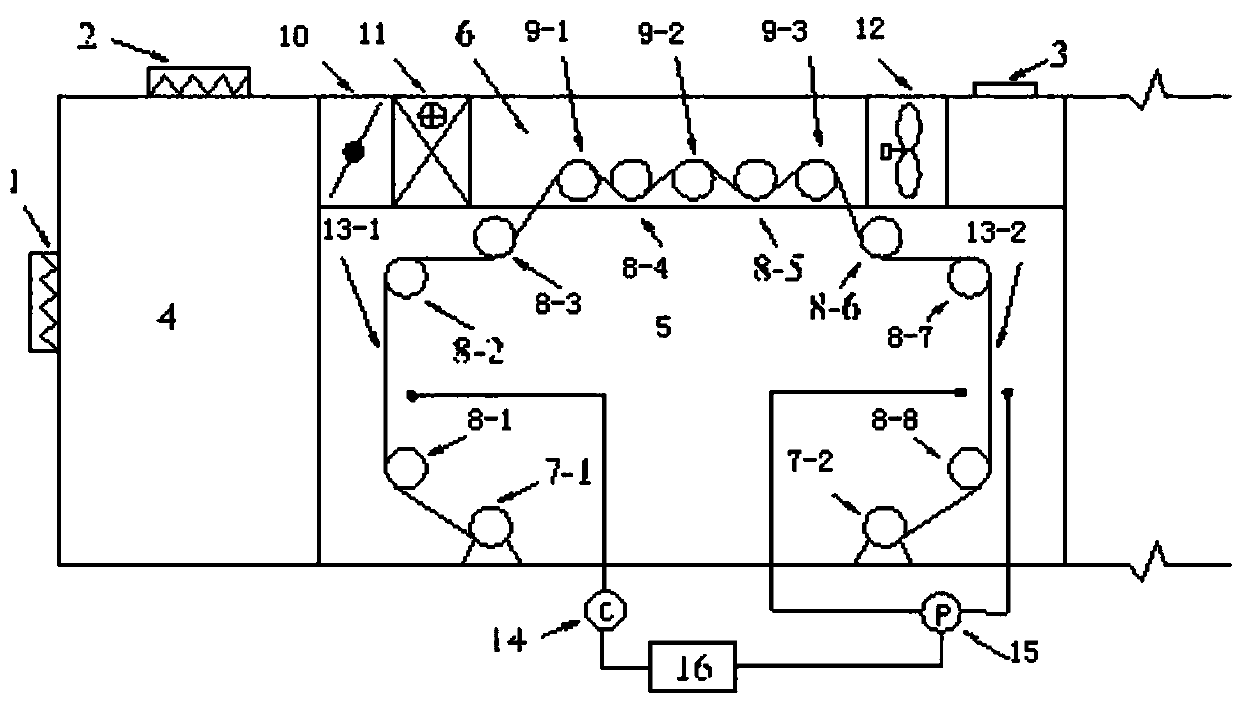

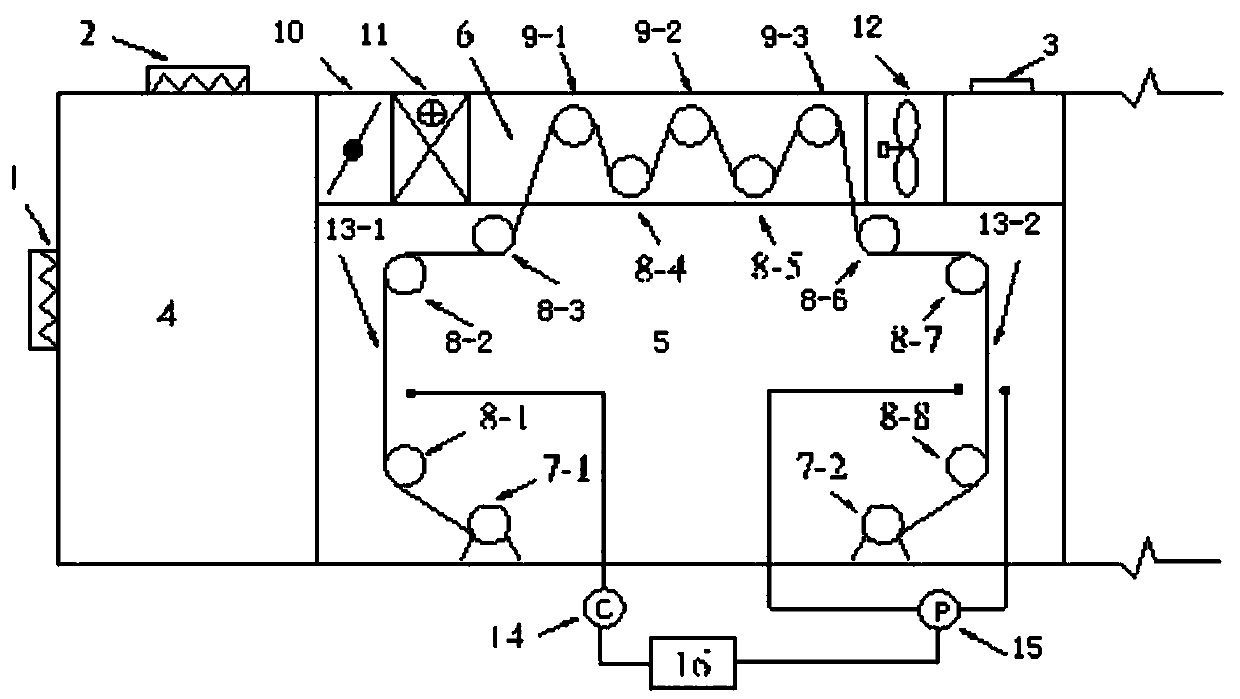

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes a fresh air outlet 1, a return air outlet 2, an exhaust outlet 3, a mixing section 4, a filtering section 5, a regeneration section 6, and two driving wheels 7 (driving wheel 7-1, driving wheel 7-2) , eight fixed driven wheels 8 (fixed driven wheels 8-1, fixed driven wheels 8-2, fixed driven wheels 8-3, fixed driven wheels 8-4, fixed driven wheels 8-5, fixed driven wheel 8-6, fixed driven wheel 8-7, fixed driven wheel 8-8), three movable driven wheels 9 (movable driven wheel 9-1, movable driven wheel 9-2 , movable driven wheel 9-3,), electromagnetic air valve 10, electric heater 11, axial fan 12, filter material 13, gas sensor 14, differential pressure transmitter 15, programmable logic controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com