Flue gas purification tower

A flue gas purification tower, tower body technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., to achieve the effect of improving uniform distribution and improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] Preferred embodiment:

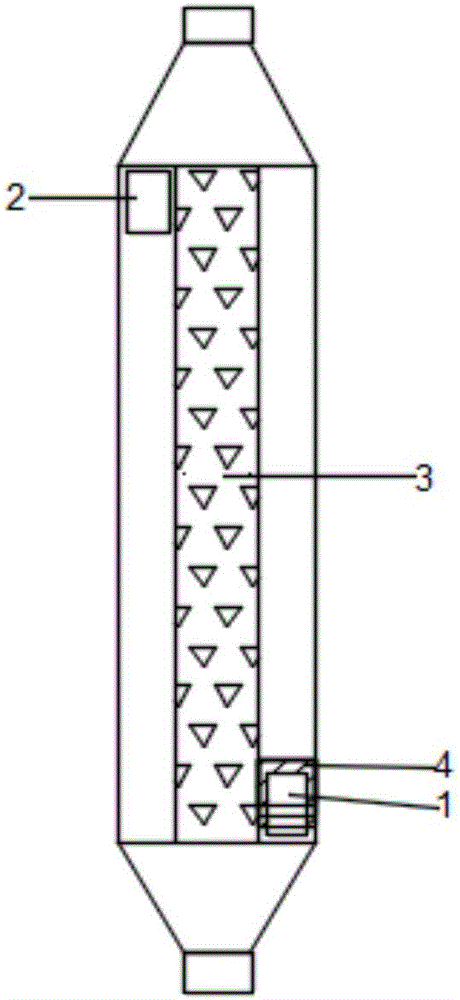

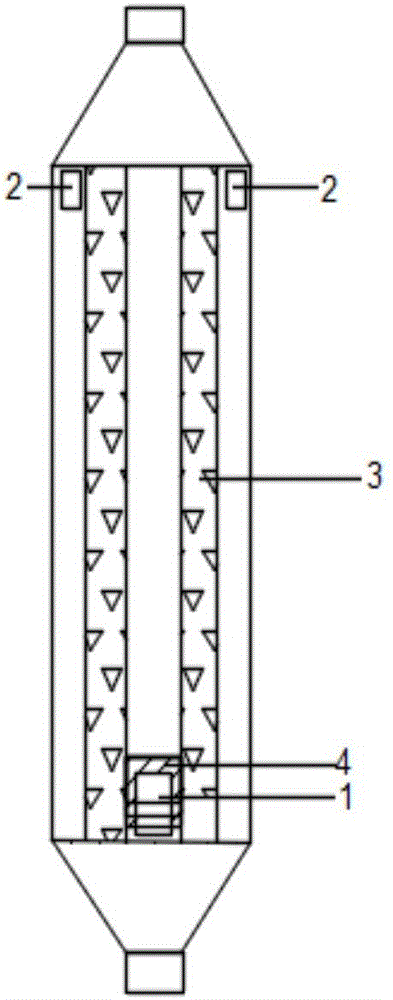

[0029] This preferred embodiment discloses a flue gas purification tower, the flue gas purification tower is mainly aimed at desulfurization and denitrification of flue gas by activated coke method. The flue gas purification tower includes a tower body, at least one air inlet 1 arranged at the bottom of the tower body, at least one gas outlet 2 arranged at the top of the tower body, at least one layer of active coke layer 3 located in the tower body, and at the inlet 1 The baffle plate 4 arranged at the point where the flue gas flow changes direction, wherein, the flue gas flow at the air inlet 1 is parallel to the active coke layer 3 flow, such as figure 1 with figure 2 shown.

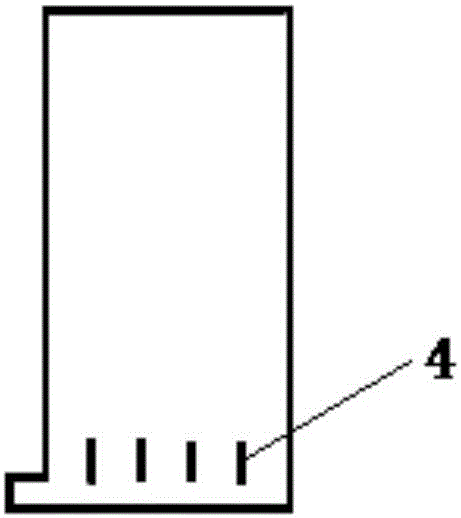

[0030] Such as image 3 with Figure 4 As shown, the baffles 4 are straight plates, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com