Disinfectant mixing device for supplementing residual chlorine between pipe networks

A mixing device and disinfectant technology, which is applied in mixers, fluid mixers, transportation and packaging, etc., can solve the problems that static mixers cannot meet the mixing effect of medicines and water head loss at the same time, so as to avoid the difference in residual chlorine concentration, The effect of reducing energy loss and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

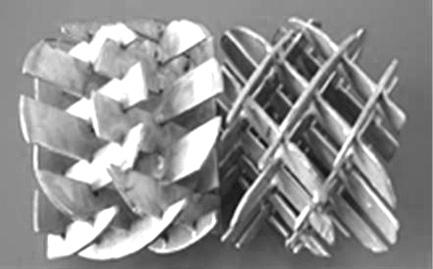

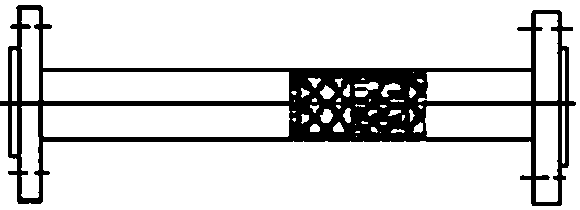

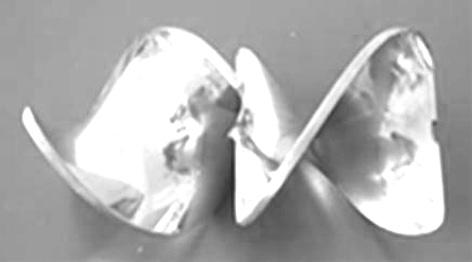

[0038] A disinfectant mixing device for replenishing residual chlorine between pipe networks, including a water delivery pipe 1, the inner wall of the water delivery pipe 1 is fixed along the length direction of the water delivery pipe 1 with a plurality of guide vanes 3 with a certain height perpendicular to the inner wall of the water delivery pipe 1 , the front section of the guide vane 3 is parallel to the axis of the water delivery pipe 1 , and the rear section of the guide vane 3 is gently twisted in the same direction along the circumference of the water delivery pipe 1 .

[0039] The number of the guide vanes is 3-4. The total length of the guide vane 3 is 2 to 4 times the inner diameter D of the water delivery pipe, and the length of the front section of the guide vane 3 is 0.2 to 0.5 times the total length of the guide vane 3 . The ratio of the height h of the guide vane to the inner diameter D of the water delivery pipe is 0.3-0.35. The twist angle α between the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com