Liquid chemical raw material mixing kettle

A technology of chemical raw materials and mixing kettles, which is applied to mixers, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve the problems of dead ends in the mixing process, increased mixing time, and low efficiency, so as to improve efficiency and reduce Effect of mixing time, time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

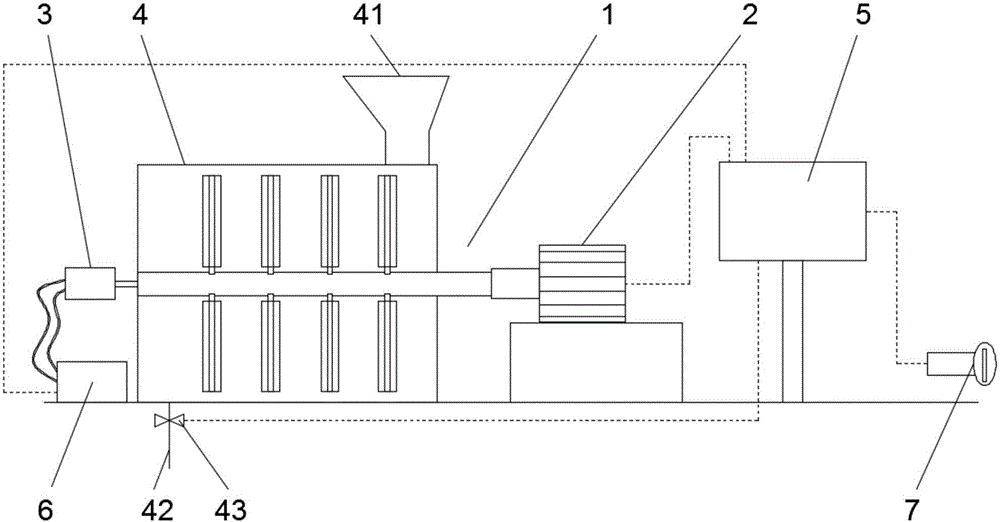

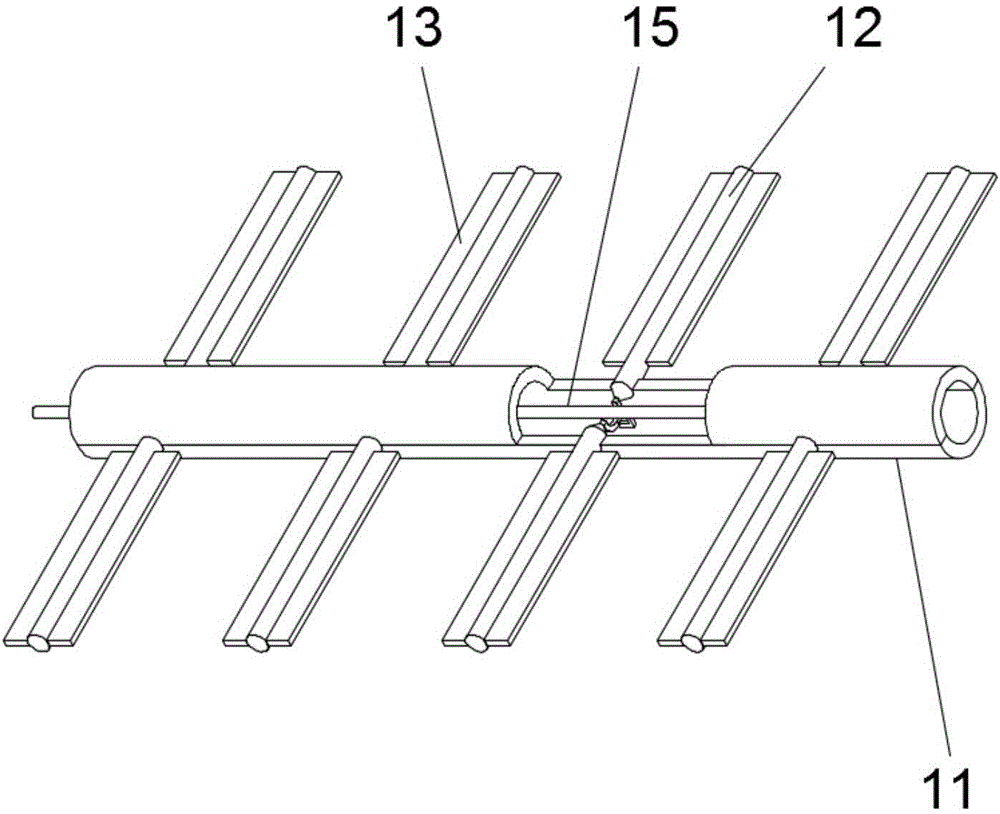

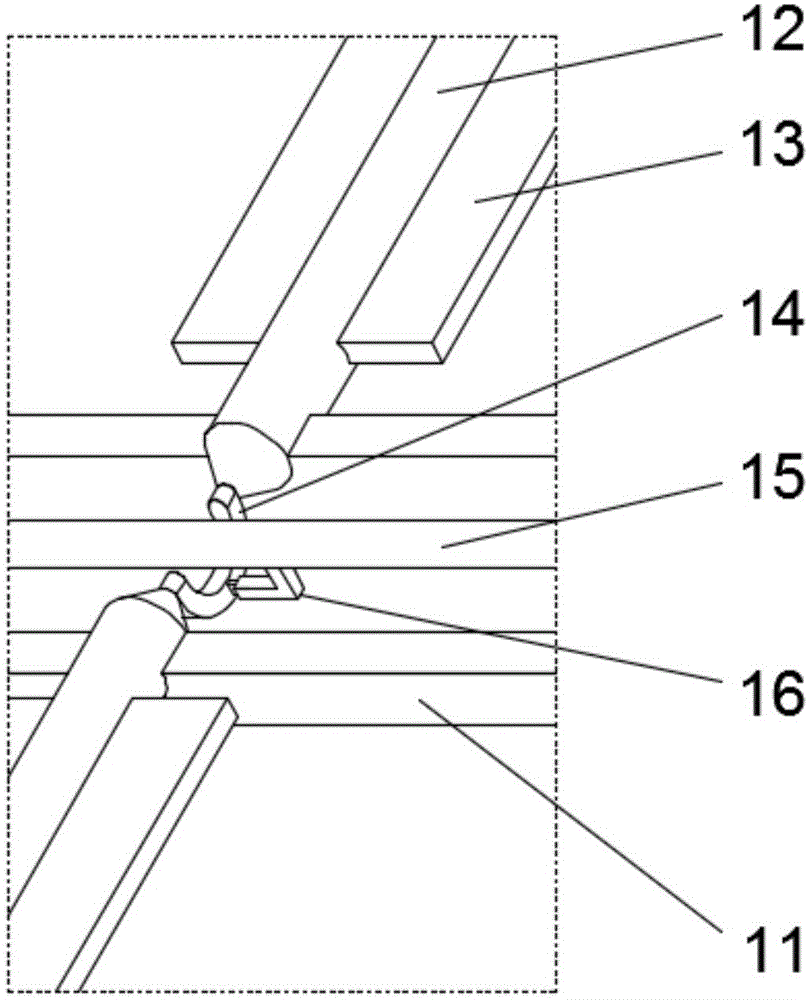

[0015] Such as Figure 1 to Figure 3 As shown, this embodiment provides a liquid chemical raw material mixing kettle, which includes a horizontal cylindrical kettle body 4; the top right side of the kettle body 1 is provided with a feed port 41, and the bottom left side is provided with a discharge port. port 42; the discharge port 42 is provided with a valve 43; the mixing device 1 is arranged in the kettle body 4; the right end of the mixing device 1 is connected to the motor 2, and the left end passes through the kettle body 4 and is connected to the hydraulic cylinder 3; The hydraulic cylinder 3 is connected to the hydraulic station 6; the mixing device 1 includes a hollow rotating shaft 11 composed of two semicircles; a plurality of mixing rods 12 perpendicular to the rotating shaft 11 are evenly distributed in pairs on the rotating shaft 11; The upper and lower sides of 12 are respectively provided with stirring plates 13; the inner axis position of the rotating shaft 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com