Automatic board brushing method for charger PCBA boards

A charger and automatic brushing technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of large impact on cleaning quality, inconsistent product quality, high labor costs, etc., to achieve brushing The board time is short, the assembly line capacity is improved, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

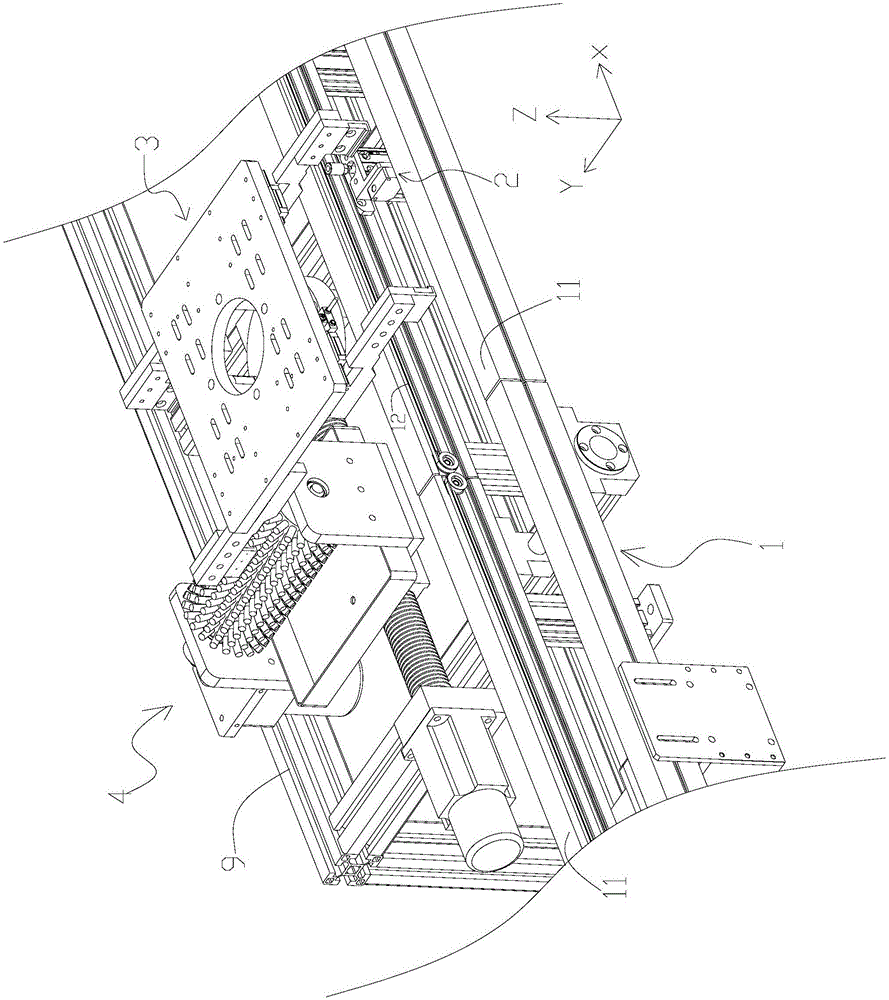

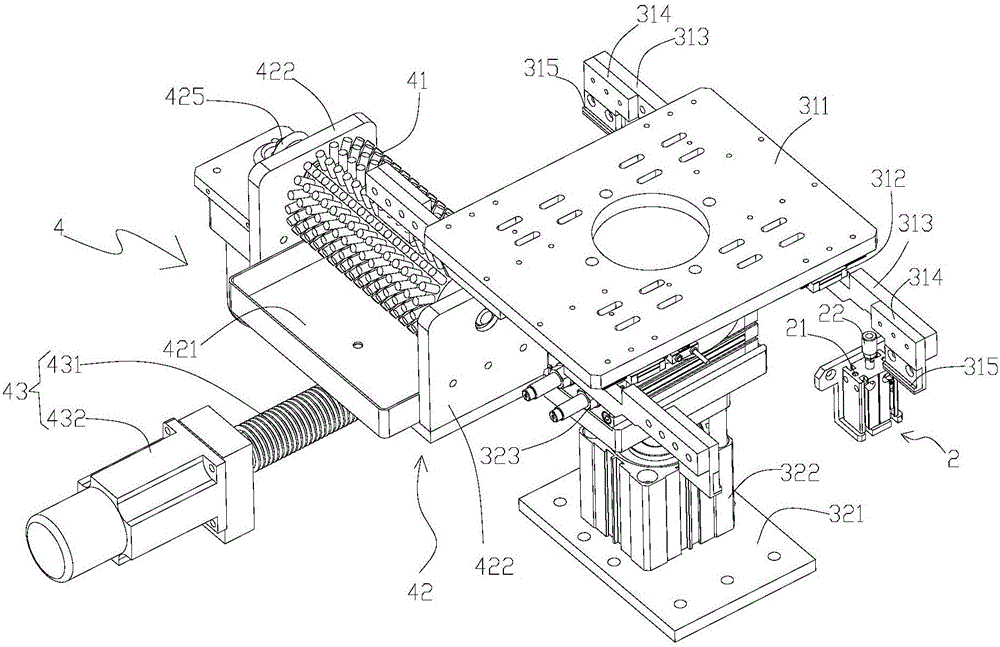

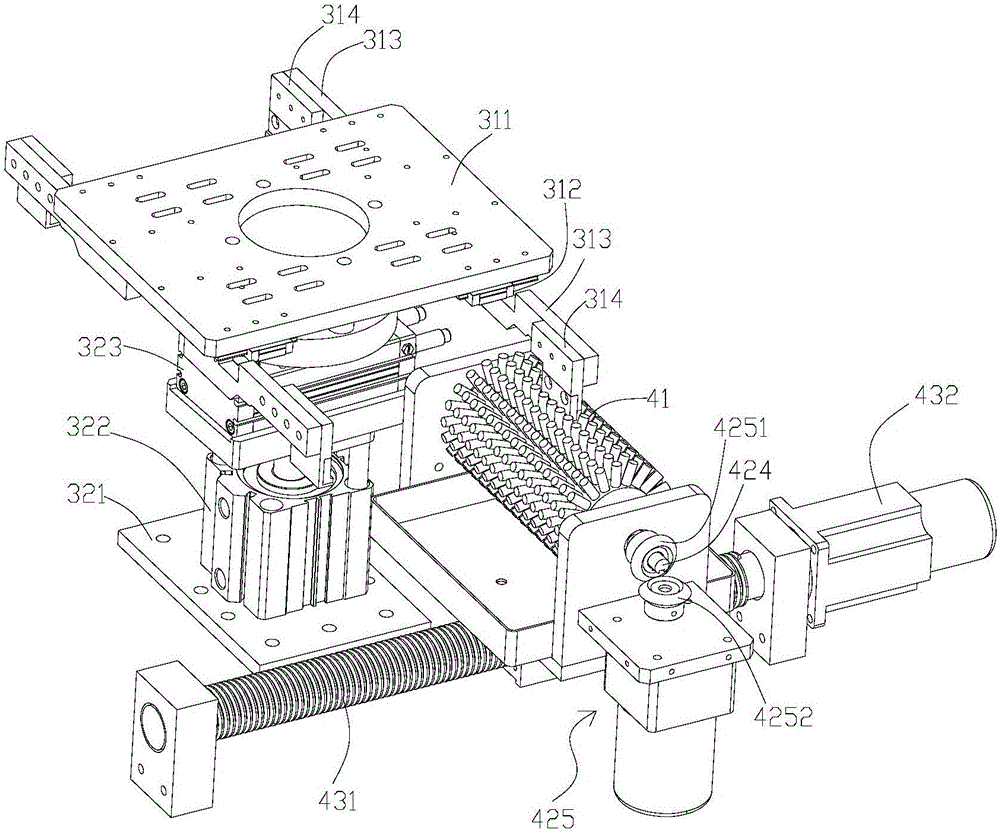

[0030] For the convenience of description, such as figure 1 As shown, in the embodiment, the longitudinal direction of the automatic conveying device 1 is defined as the X direction in the three-dimensional coordinates, the lateral direction of the automatic conveying device 1 is defined as the Y direction, and the direction of the plane perpendicular to the X direction and the Y direction is defined as In the Z direction, all brackets used to support or fix the components on the charger PCBA board automatic brushing machine are collectively referred to as brackets 9 .

[0031] A method for automatically brushing a charger PCBA board according to the present invention comprises the following steps:

[0032] Step 1, stop the uncleaned PCBA board synchronously moving with the automatic conveying device 1 at a designated position;

[0033] Step 2, the PCBA board that has been stopped and not brushed is taken away from the automatic conveying device 1, and transferred to the brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com