Spiral reinforcing rib manufacturing equipment

A technology for reinforcing ribs and equipment, which is applied in the field of equipment for making spiral reinforcing ribs, can solve the problems of affecting the welding process, the contact between the spiral reinforcing ribs and ground anchor piles is not tight, and the like, and achieve the effect of improving the firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

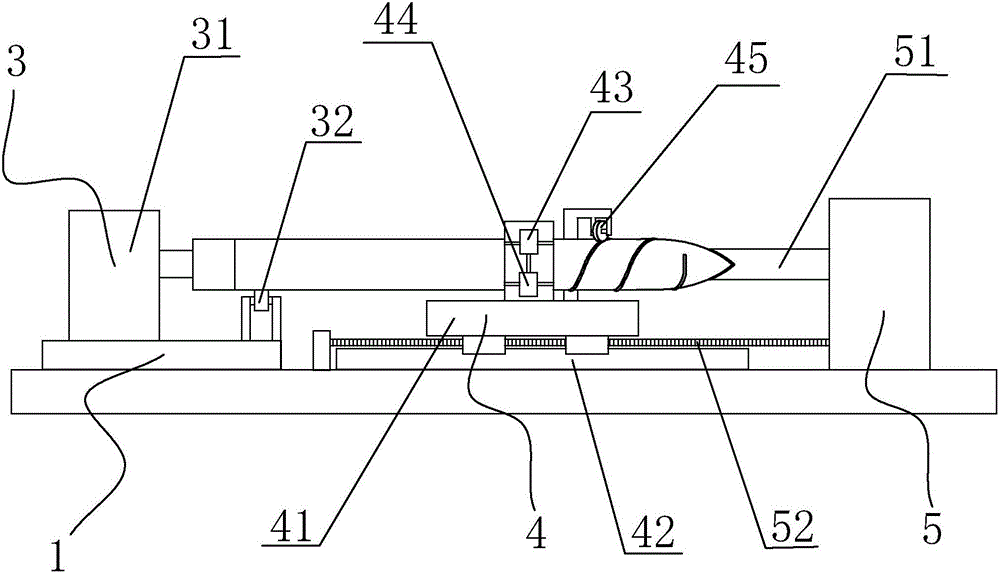

[0012] refer to figure 1 , a kind of equipment of making spiral reinforcement of the present invention, comprises equipment body 1, and equipment body 1 comprises control device, is used for driving the first driving device 3 of ground anchor pile to rotate, is used for making spiral reinforcement on the surface of ground anchor pile The reinforcing rib driving device 4 of the rib and the second driving device 5 for driving the ground anchor pile to rotate and driving the reinforcing rib driving device 4 to move horizontally, the first driving device 3 includes a rotating shaft for driving the ground anchor pile to rotate The motor 31, the reinforcing rib transmission device 4 includes a reinforcing rib slide table 41 and a transmission guide rail 42 for enabling the reinforcing rib slide table 41 to move horizontally, the reinforcing rib slide table 41 is arranged on the transmission guide rail 42, and the reinforcing rib slide table 41 The first guide pulley 43 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com