Double flanges H-shaped stainless steel valve body multi-way precision forming device

A precision forming, stainless steel technology, applied in valve devices, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of complex production process, low production efficiency, inclusions, etc., to achieve simple installation and replacement, strong device compatibility, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

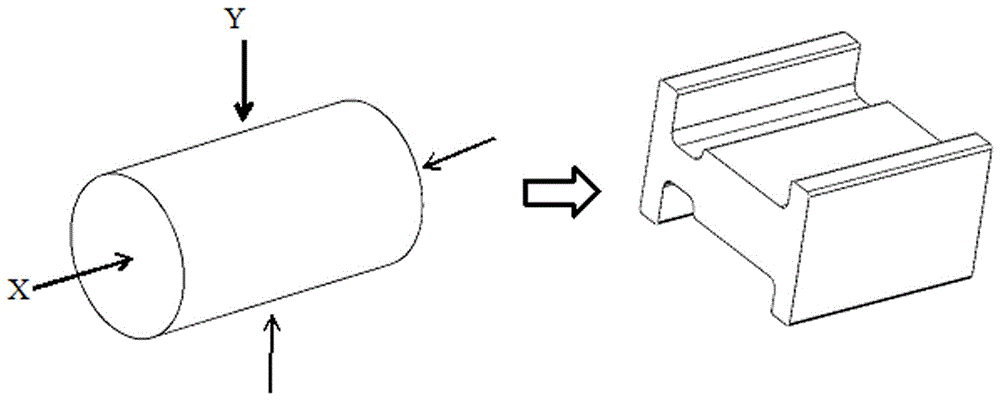

[0019] Such as figure 1 As shown, in this embodiment, the forging is formed by extruding the billet from the horizontal X direction and the vertical Y direction, and the device should be installed on a four-direction forming press.

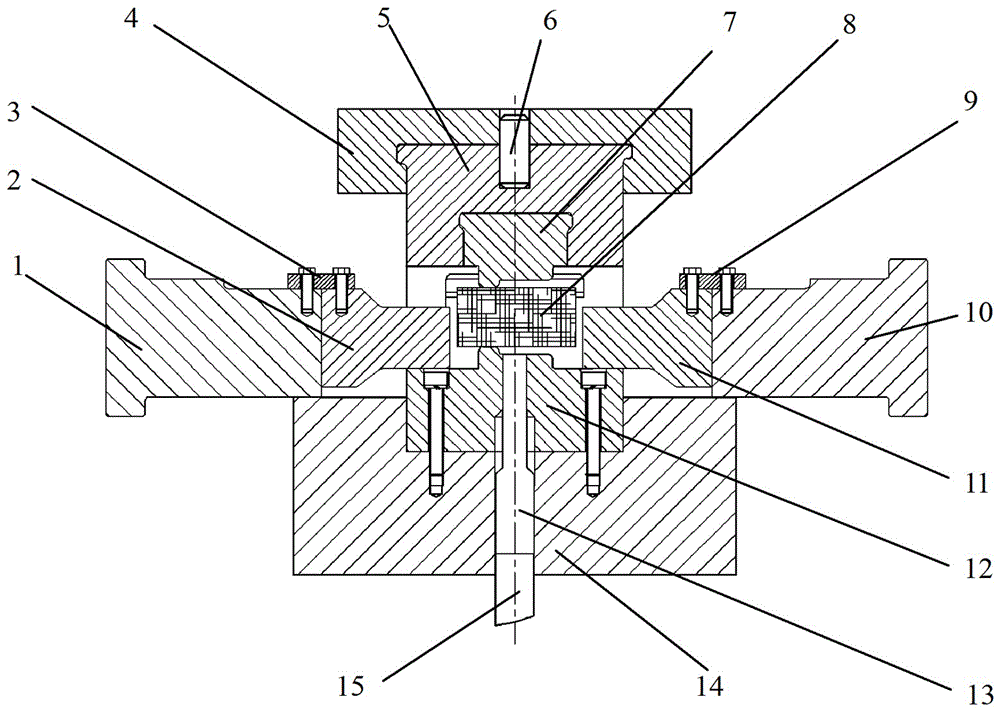

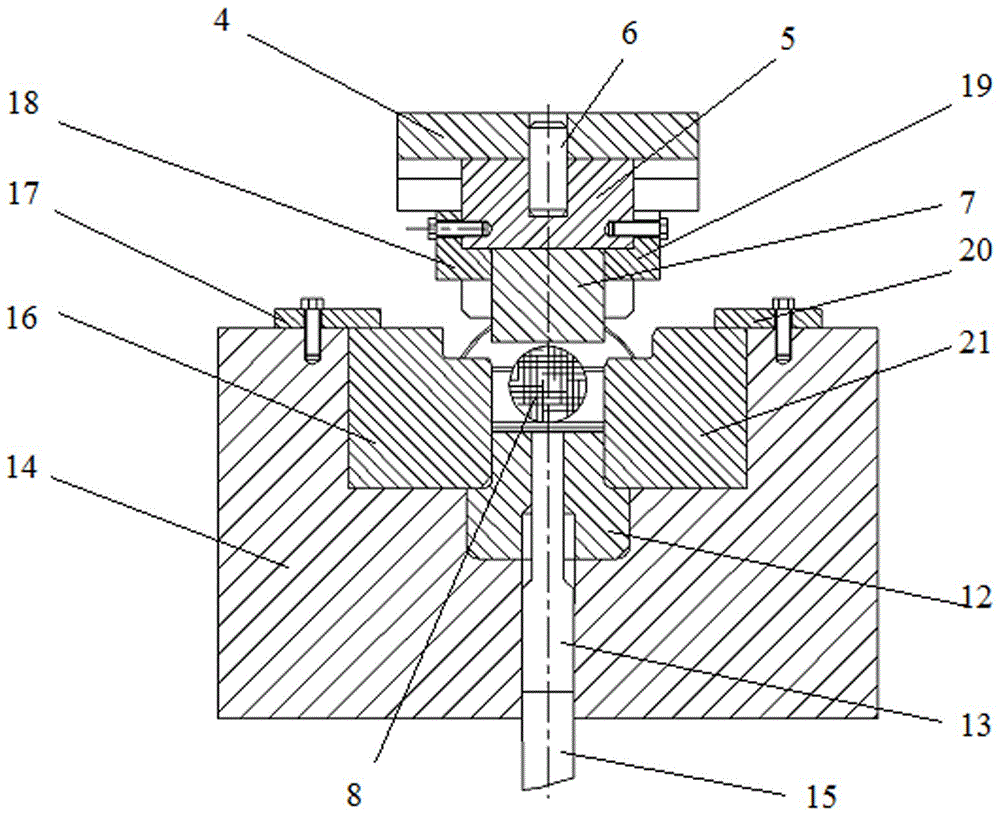

[0020] Such as figure 2 , 3 , shown in 4, double-flange I-shaped stainless steel valve body multidirectional precision forming device of the present invention comprises left extrusion die assembly, right extrusion die assembly, upper extrusion die assembly, four parts of following extrusion die assembly; The compression die assembly includes a left punch connecting rod 1 and a left punch 2; the right extrusion die assembly includes a right punch connecting rod 10 and a right punch 11; the upper extrusion die assembly includes an upper Backing plate 4, punch cushion block 5, upper punch 7; the lower extrusion die assembly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com