Compact iron casting automatic cleaning system

A kind of iron casting, compact technology, applied in the field of automatic cleaning system for compact iron castings, can solve the problems of error-prone, unable to achieve posture, few types of tools, etc., to achieve the effect of ensuring cleanliness and facilitating debris removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

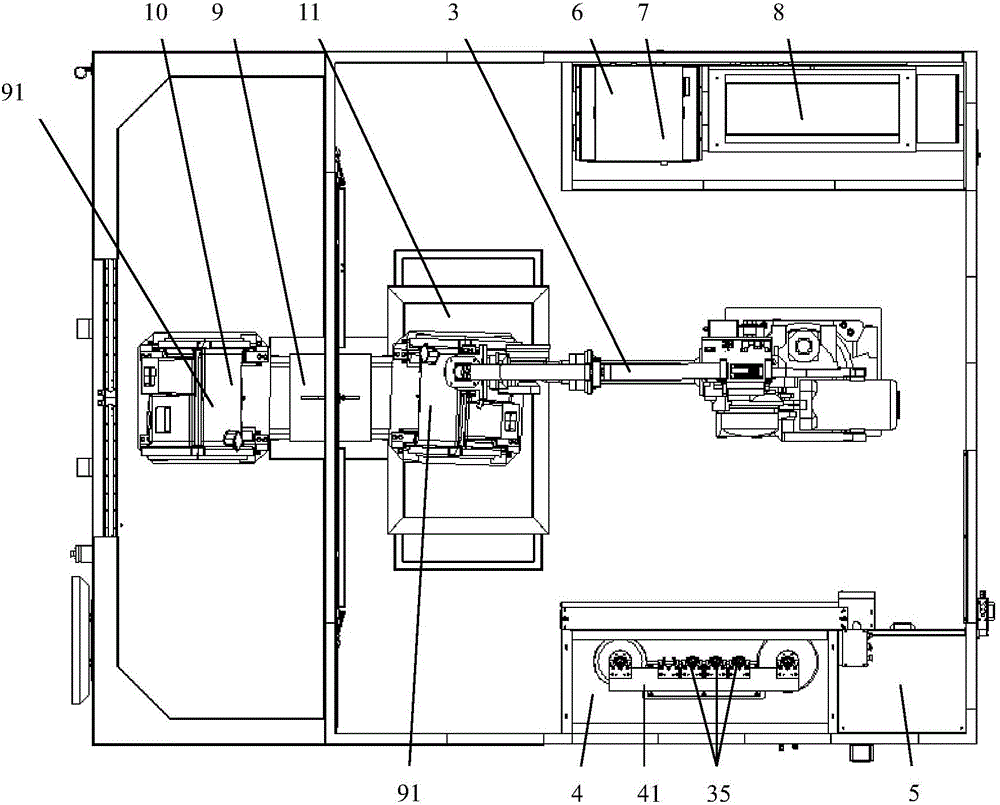

[0036] In a further embodiment of the present invention, the side of the tool magazine protection room 4 facing the robot 3 is provided with a rolling door, and the opening and closing of the tool magazine protection room 4 is controlled by the rolling door to ensure that the tool magazine environment is clean and dust-free.

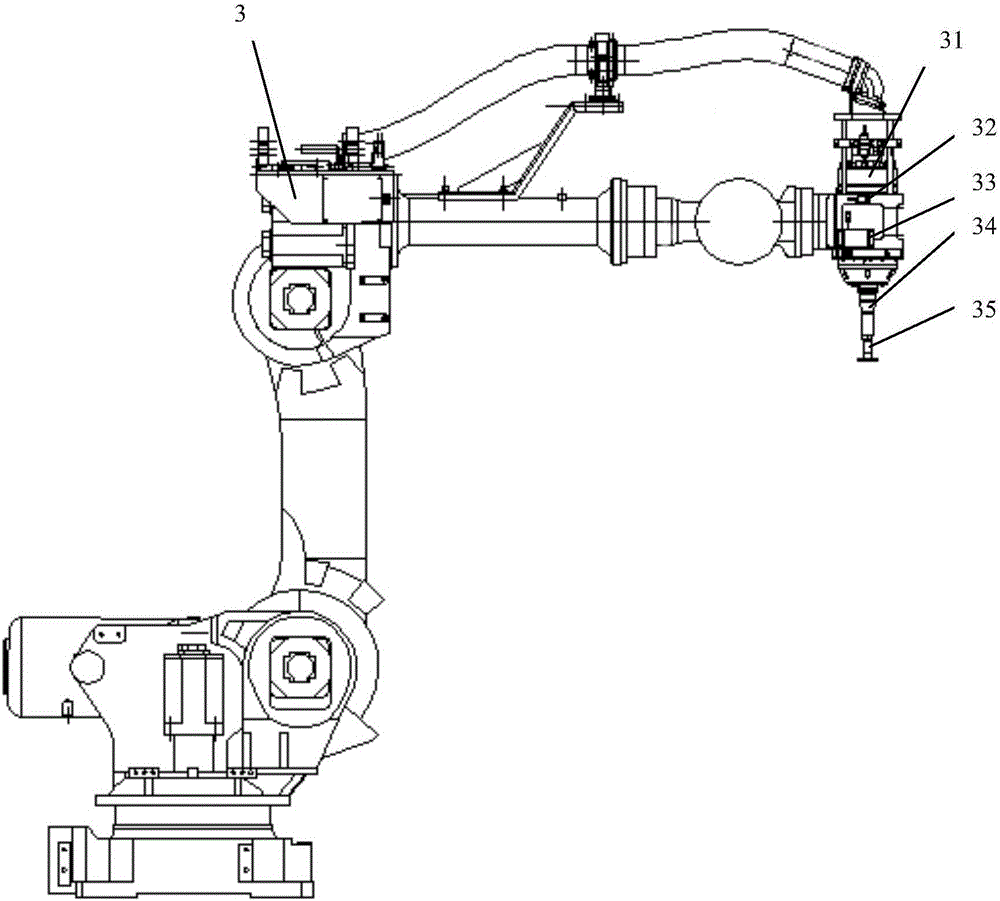

[0037] In a further embodiment of the present invention, the handles 34 of several cutters 35 are T-shaped groove profiling designs, and are matched with each other.

[0038] In a further embodiment of the present invention, the electric spindle 31 is equipped with elastic clamping jaws, and the elastic clamping jaws match the profiling design of the T-shaped groove of the handle 34 . Through the profiling design of the T-shaped groove of the tool handle 34 and the elastic jaws, the automatic replacement of the tool 35 is satisfied, and the amount of tool spit out by the electric spindle 31 can be compensated.

[0039] In a further embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com