Machine tool main shaft module

A machine tool spindle and spindle technology, applied in the field of machine tools, can solve problems such as spindle distortion and deformation, and achieve the effects of reducing distortion and deformation force, high precision and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

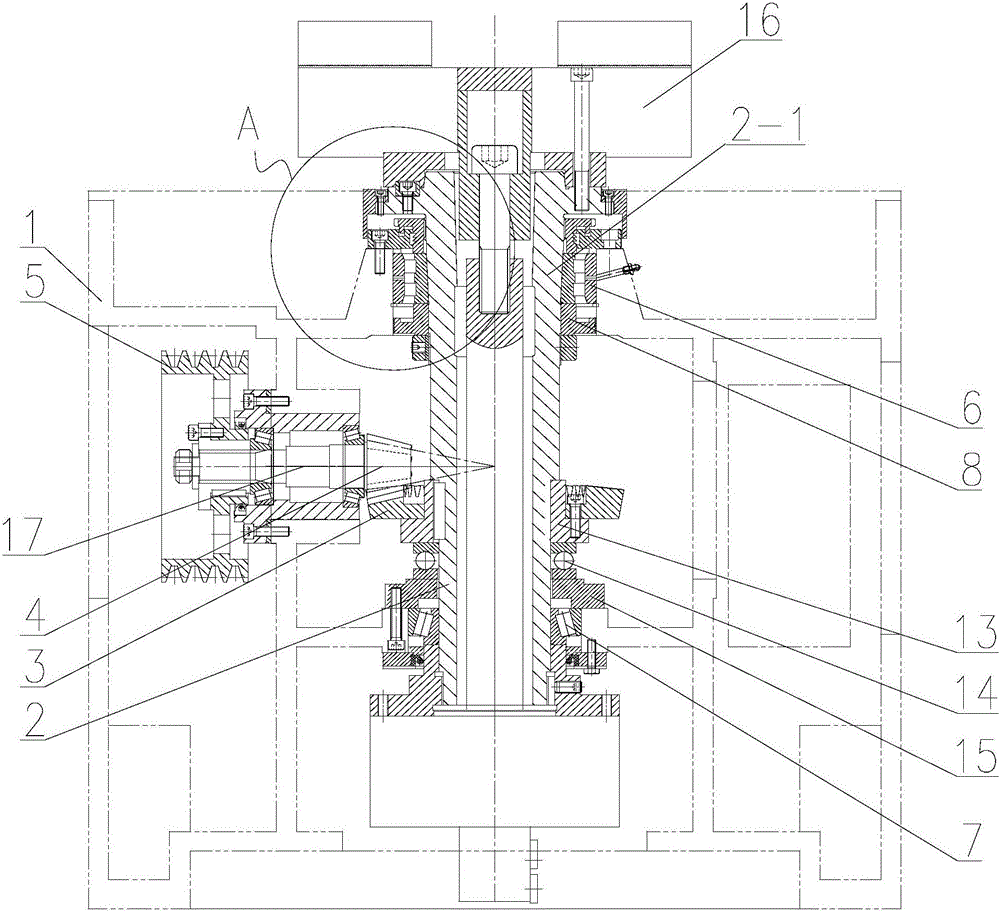

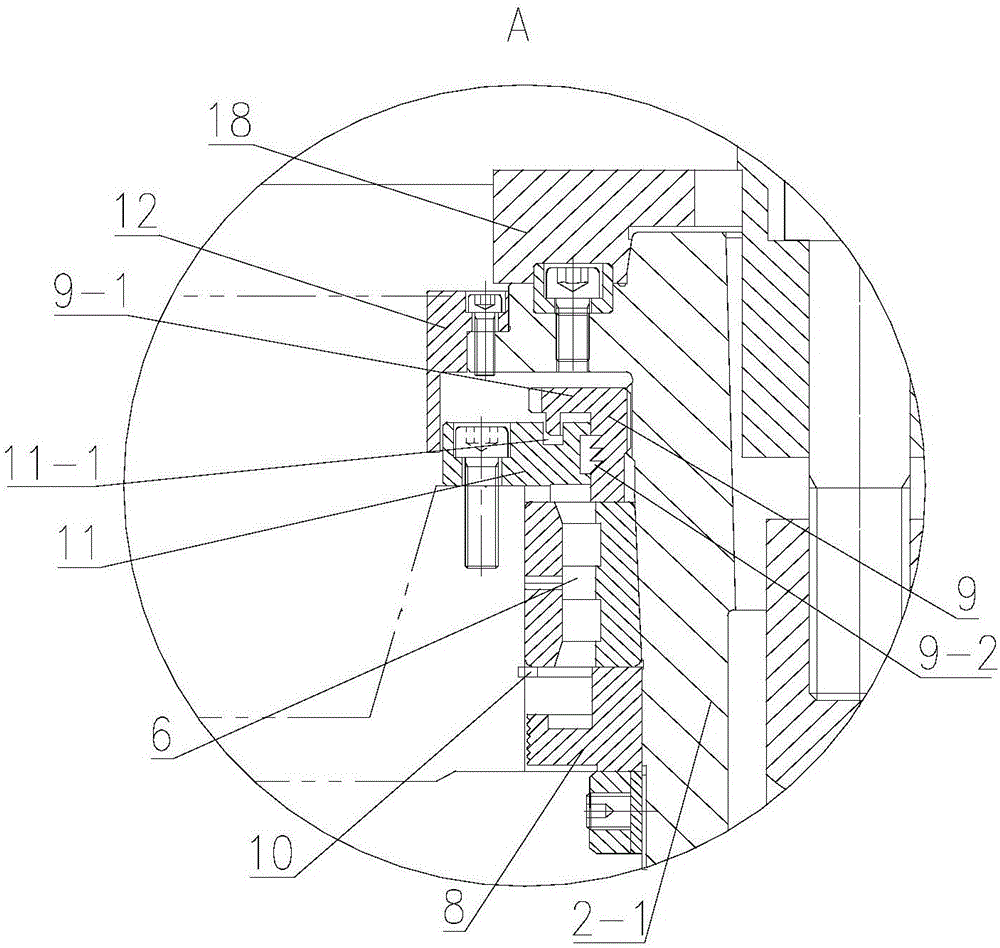

[0021] Such as figure 1 with 2 As shown, a spindle module of a machine tool includes a casing 1 and a spindle 2 rotatably installed in the casing 1. The front end of the spindle 2 is fixed with a connection plate 18 and a chuck 16. The front end and the rear end of the spindle 2 are connected to the casing 1. Bearings are arranged between them, the middle part of the main shaft 2 is fixed with a driven wheel 3, and the transmission shaft 17 is arranged on the side of the main shaft 2 on the box body 1. One end of the transmission shaft 17 is fixed with a pulley 5, and the other end is fixed with a driving wheel. Wheel 4, the driving wheel 4 is connected to the driven wheel 3, the external main motor is connected to the pulley 5 of the transmission shaft 17 through the transmission belt, and the transmission shaft 17 drives the main shaft 2 to rotate through the transmission connection between the driving wheel 4 and the driven wheel 3 and provides certain Reduction ratio.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com