Efficient and intellectualized rotary sawing machine

A circular saw machine, high-efficiency technology, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., to achieve the effect of smooth surface, good processing quality and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

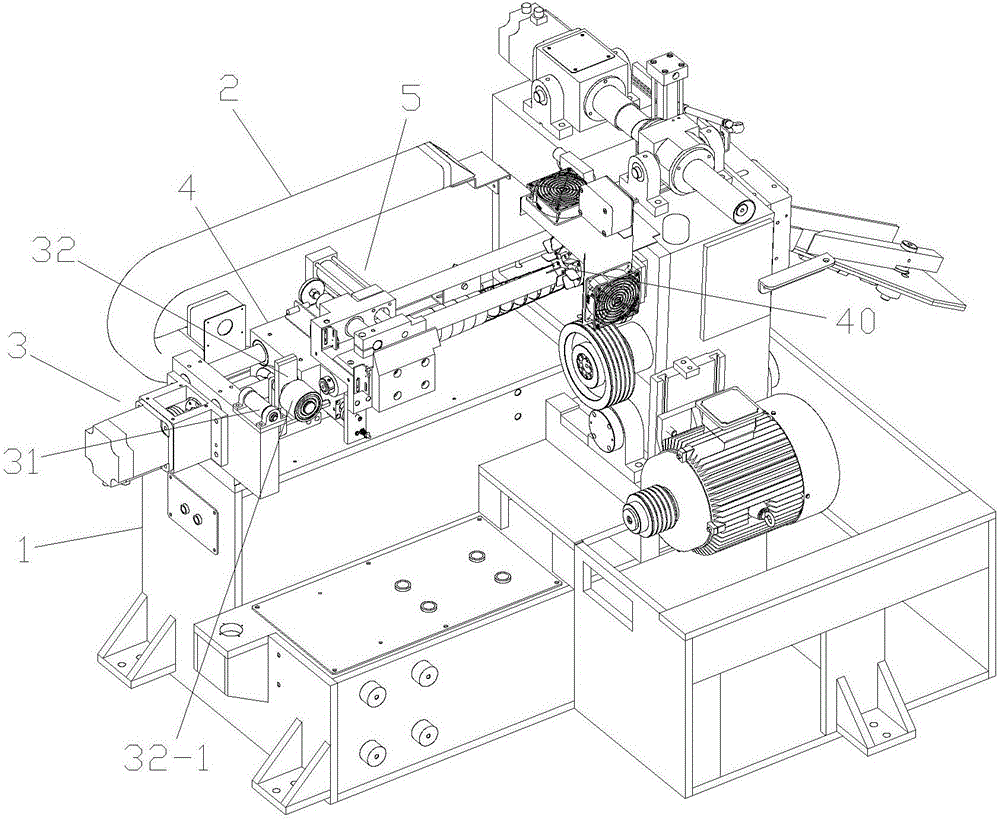

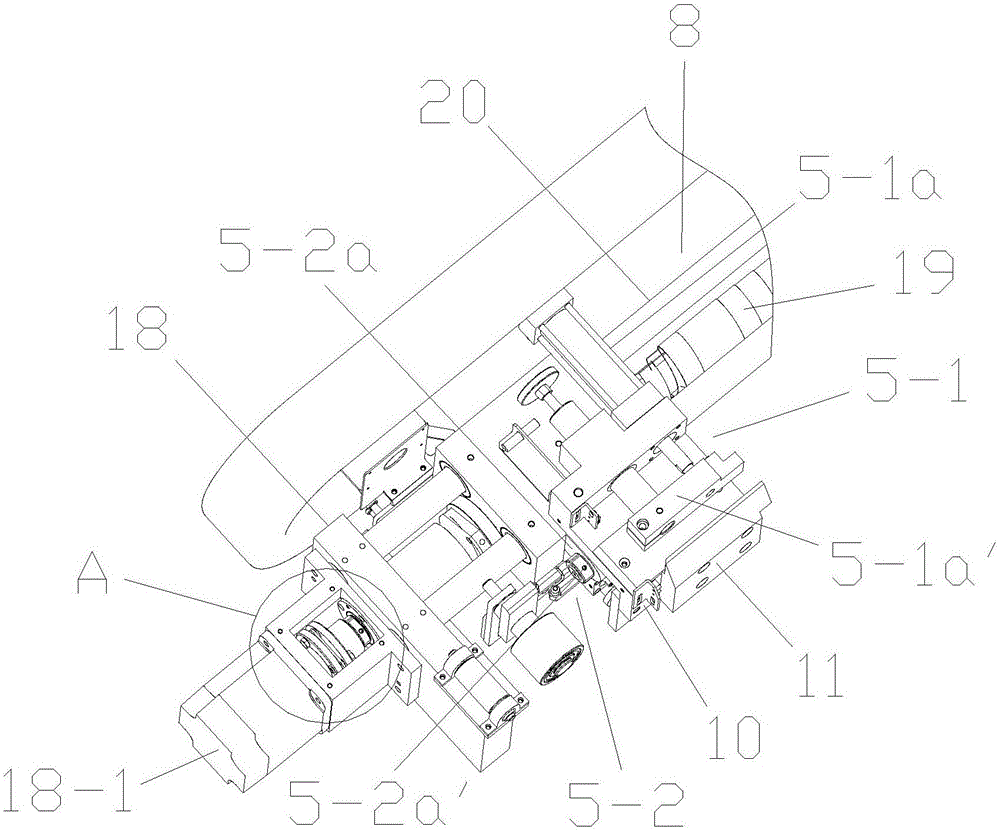

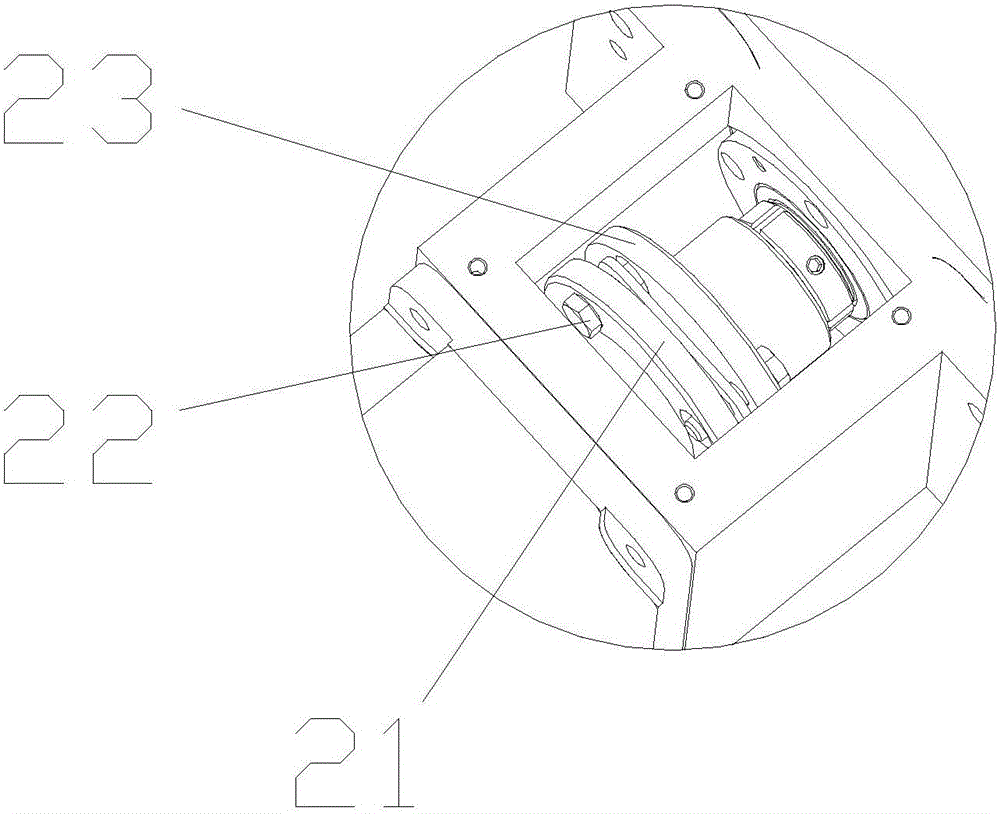

[0030] Referring to the accompanying drawings: this high-efficiency and intelligent circular saw machine includes a machine base 1, a feeding part 2 is provided on the machine base 1, a driving unit 3 that provides a power source effect is provided on the feeding part 2, and a drive unit 3 is slidably connected with a The sliding seat 4 is provided with an adjusting device 5 for adjusting the position of the workpiece; the front end of the feeding part 2 is provided with a clamping part 6 fixed on the machine base 1, and the clamping part 6 is provided with a first workpiece mounting seat 6- 1 and a horizontal clamping unit 6-2 and a vertical clamping unit 6-3 used in conjunction with the first workpiece mounting seat 6-1; the side of the clamping part 6 is provided with a cutting part 7 that is rotatably connected to the machine tool base 1, The cutting part 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com