Gear machining and polishing device

A technology for gears and grinding parts, which is applied in the field of gear processing and grinding devices, and can solve the problems of vibration marks and uneven grinding of saw teeth in gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

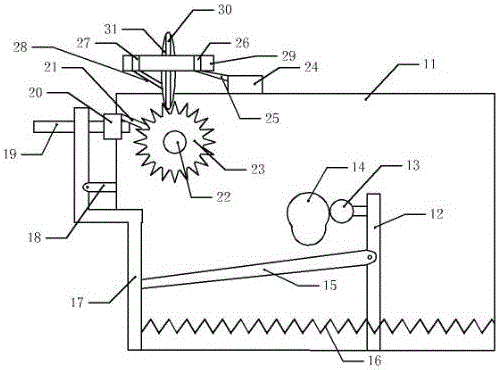

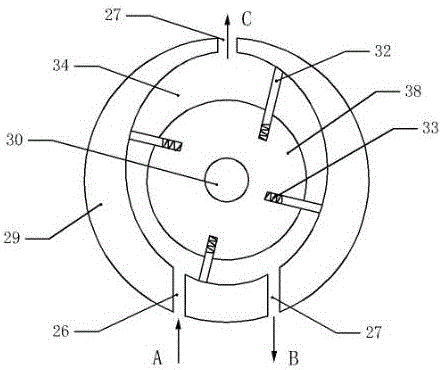

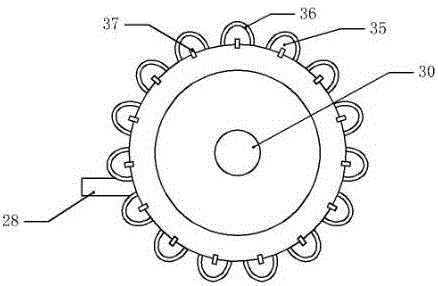

[0017] The reference signs in the accompanying drawings of the specification include:

[0018] Frame 11, vertical support plate 12, runner 13, cam 14, connecting rod 15, compression spring 16, support frame 17, elastic rod 18, screw mandrel 19, sliding sleeve 20, push plate 21, transverse shaft 22, gear 23. Blower 24, air inlet pipe 25, air inlet 26, air outlet 27, air outlet pipe 28, blade type air motor 29, rotating shaft 30, grinding part 31, blade 32, spring 33, air chamber 34, air bag 35, fine Sandpaper 36, one-way air vent 37, rotating disk 38.

[0019] Such as figure 1 The shown gear processing and grinding device includes a frame 11 and a support frame 17, a horizontal shaft 22 is fixedly installed on the upper left side of the frame 11, a gear 23 to be processed is installed on the horizontal shaft 22, the support frame 17 is placed in front of the gear 23, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com