Full-automatic welding workbench for pole lugs and caps of cylindrical batteries

A fully automatic welding, cylindrical battery technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, high labor cost, large manual operation error, etc., to reduce labor The effect of cost, good welding quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

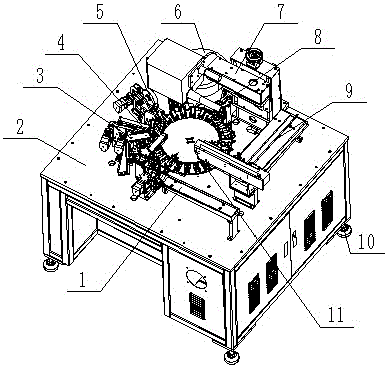

[0031] Such as Figure 1~9 As shown, a cylindrical battery tab cap automatic welding workbench includes a machine base 2 and a rotary table 11 arranged on the machine base 2, and the rotary table 11 is driven by a servo motor arranged in the machine base Driven to rotate, the inner side of the rotary table 11 is radially spaced with a number of jigs for placing the cell shell, and the outer side of the circumference is sequentially arranged along the rotation direction of the rotary table 11:

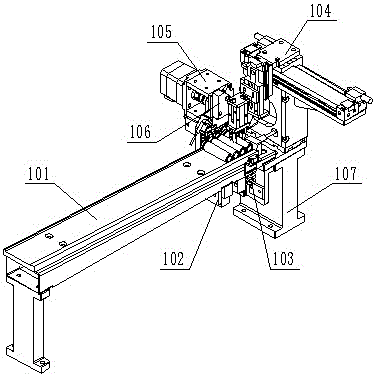

[0032] The cell casing feeding unit 1 includes a feeding support 107, a material guide trough 101 arranged obliquely on the loading support, and a feeding mechanism for clamping the cell casing to the rotary table 11 loading jig;

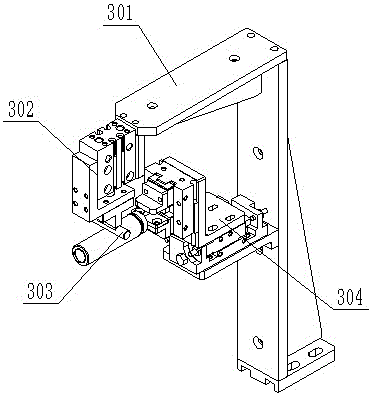

[0033] The tab leveling unit 3 includes a tab leveling support 301, a tab leveling assembly mounted on the tab le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com