Large-working-space three-translation parallel machine tool for additional redundancy arc sliding

A work space, three translation technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of long and narrow work space, waste of work space, small work space, etc., to improve the motion performance and stiffness, expand the Range of motion, effect of increasing workspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

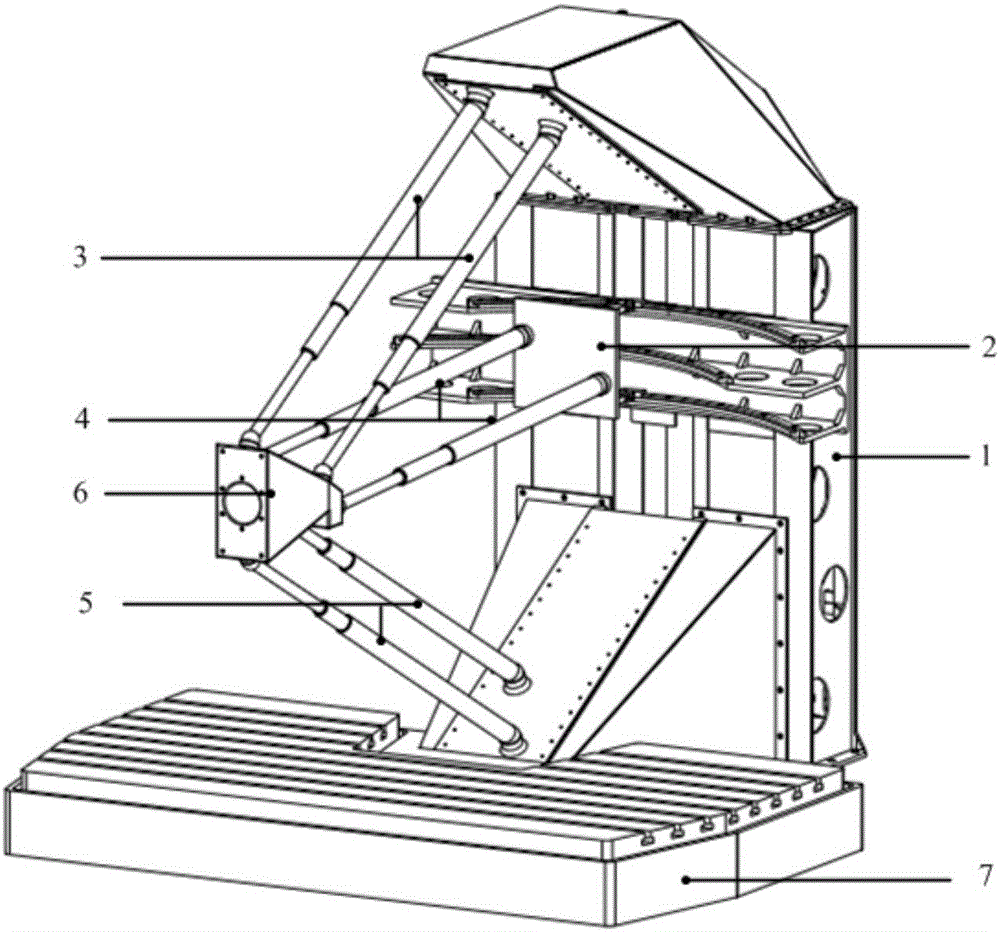

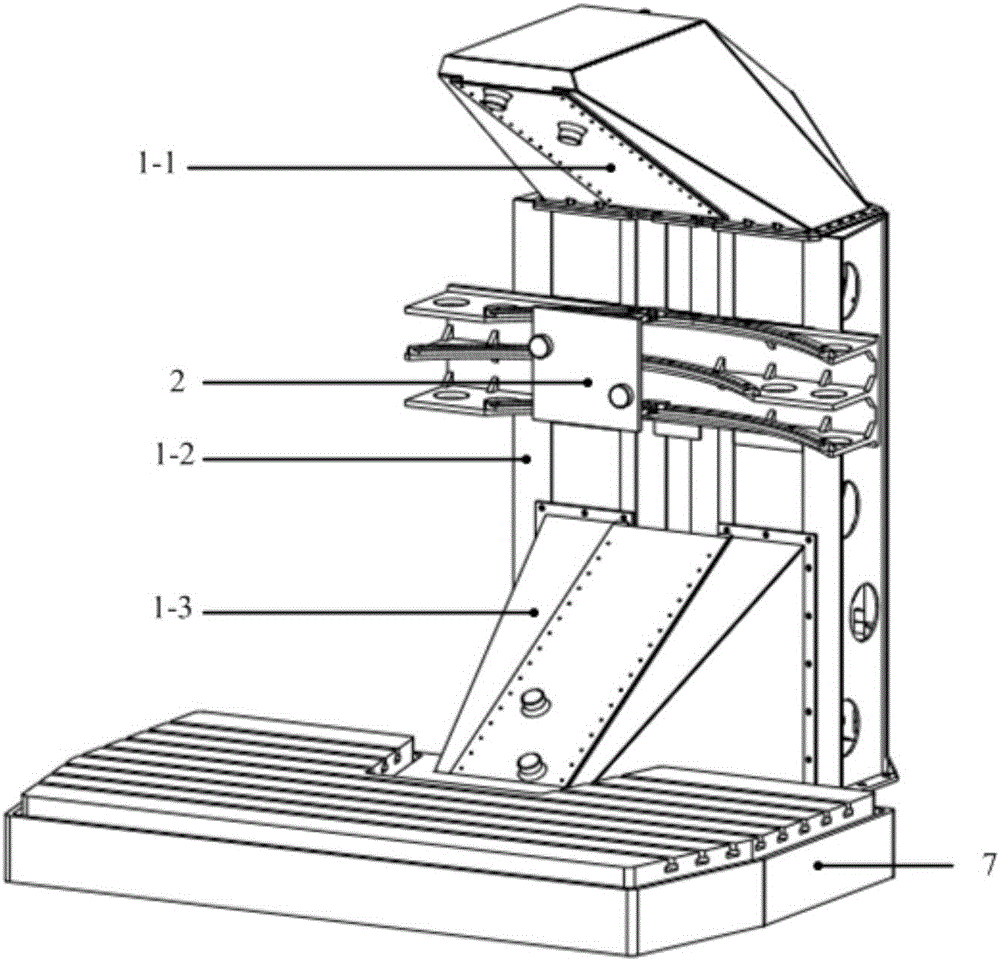

[0025] Combine below Figure 1 to Figure 8 The embodiment of the present invention is described further:

[0026] combine figure 1 , a large working space three-translational parallel machine tool with additional redundant arc sliding in the present invention, including a frame 1, an arc module 2, a first branch chain group 3, a second branch chain group 4, a third branch chain Chain group 5, moving platform 6, workbench 7;

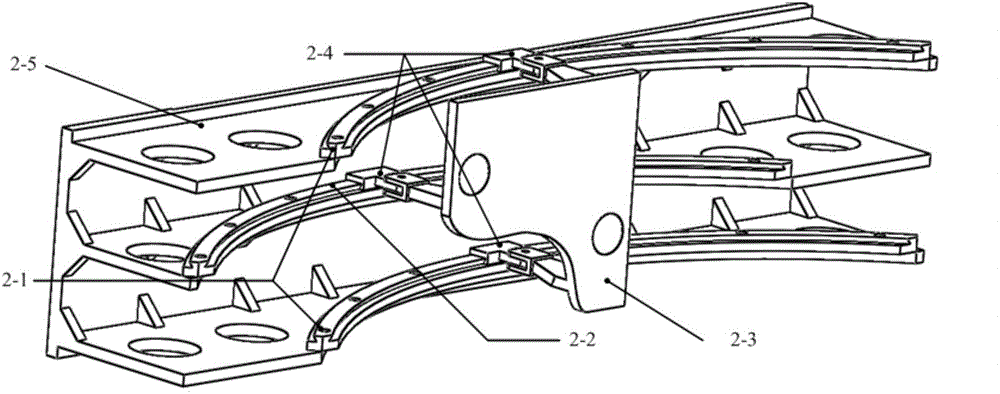

[0027] The frame 1 includes an upper support 1-1, a main column 1-2, and a lower support 1-3; the arc module 2 includes a first guide rail 2-1, a second guide rail 2-2, and a slide table 2-3, slider 2-4 and support 2-5, the arc module 2 is installed on the main column 1-2 through the support 2-5; the first guide rail 2-1 and the second guide rail 2- 2 Installed on the support 2-5, the slider 2-4 slides in an arc on the first guide rail 2-1 and the second guide rail 2-2, and the slider 2-4 is connected with the slide table 2-3 through a connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com