Accurate sand conveying device and sand conveying method

A sand feeding and precise technology, which is applied in the direction of abrasive feeding devices, abrasive materials, metal processing equipment, etc., can solve the problem of sand supply continuity, randomness, difficulty in ensuring accurate control and reliability of sand supply, and sieve hole discharge The problem of inconsistency between the level and the degree of clogging can be achieved, and the effect of improving the accuracy and stability of sand supply can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

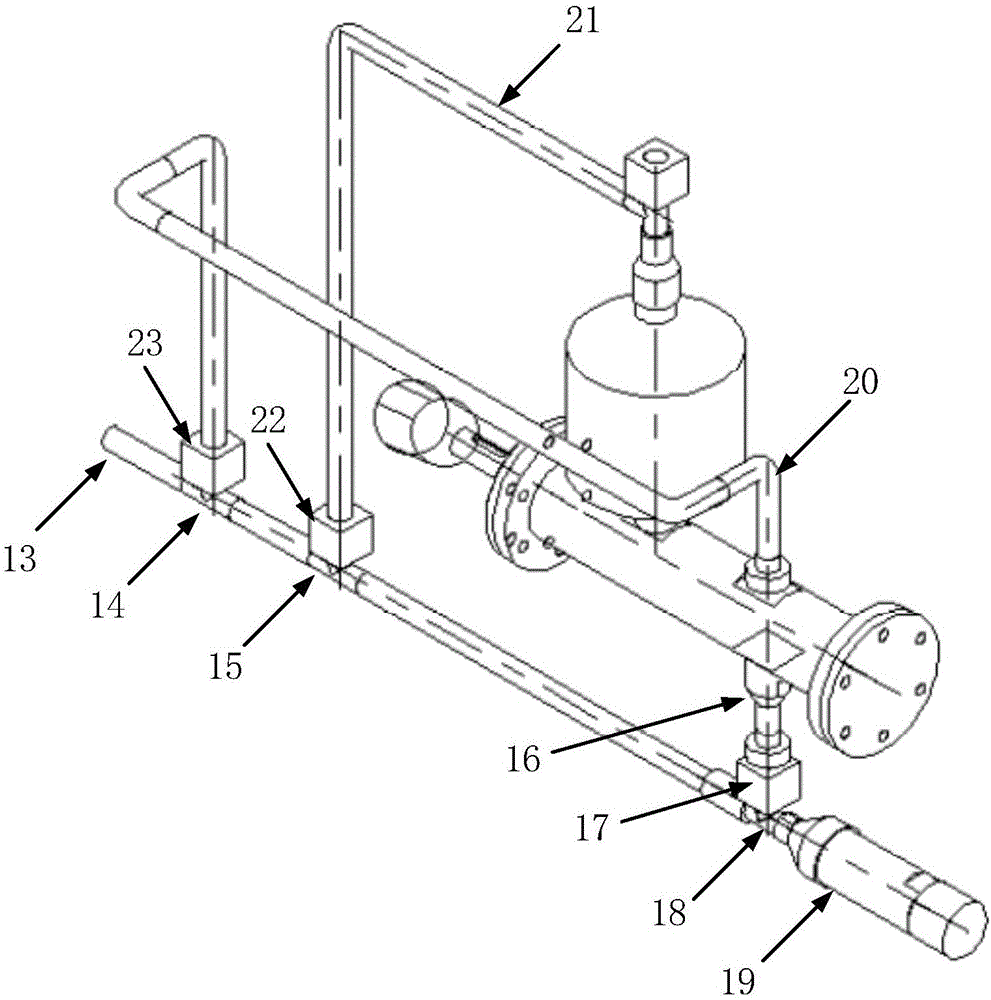

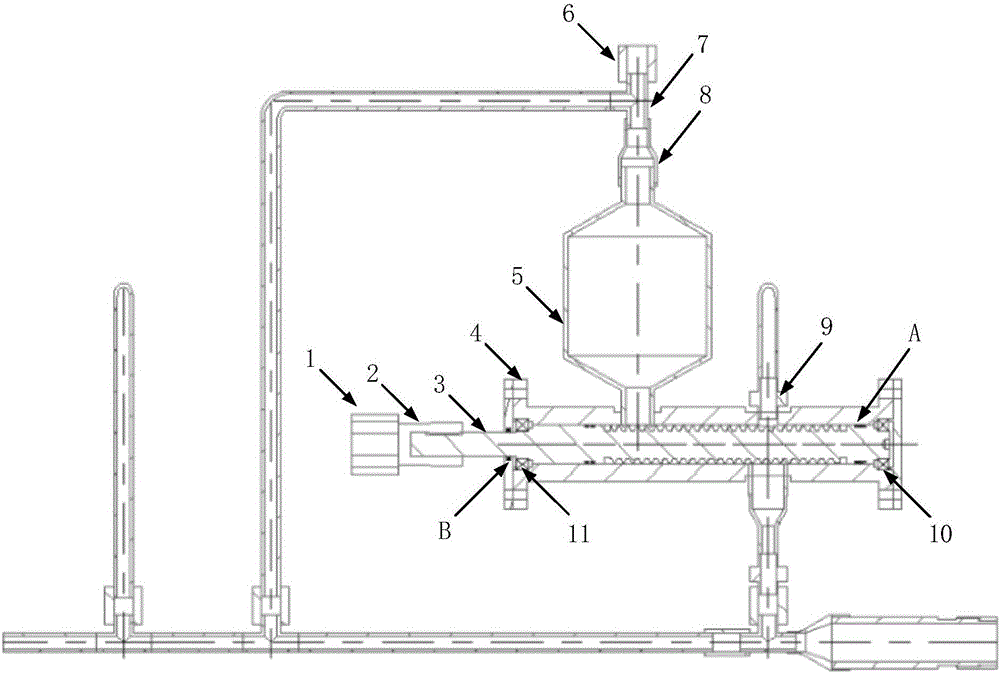

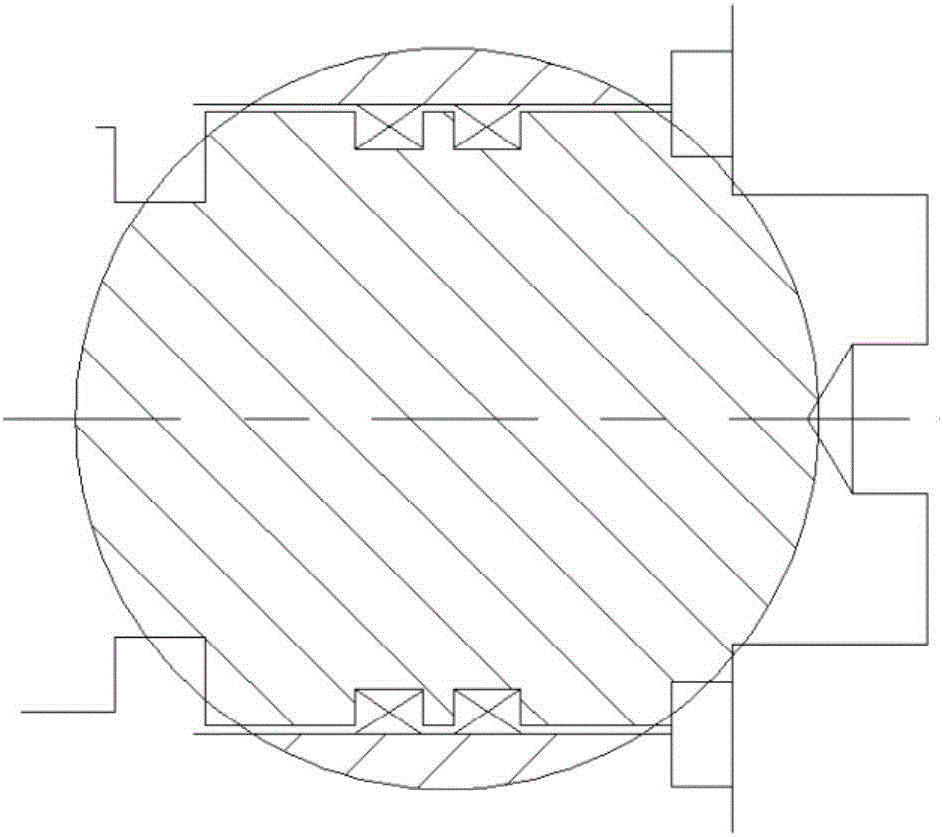

[0023] Attached below figure 1 , attached figure 2 , attached image 3 And attached Figure 4 The specific embodiment of the present invention will be further described.

[0024] The invention is an accurate sand supply device suitable for high pressure environment. The right side of the main airflow input pipe 13 is a three-way pipe 14; the right side of the three-way pipe 14 is a four-way pipe, which is then connected to the three-way pipe 15; the right side of the three-way pipe 15 is a four-way pipe, which is then connected to the three-way pipe 18; the right side of the tee pipe 18 is the main airflow output pipe 19; the airflow flowing through the pipelines 13, 14, 15, 18 and 19 is the main airflow with higher pressure.

[0025] The upper side of the three-way pipe 14 is connected with a solenoid valve 23, and the upper side of the solenoid valve 23 is connected with an auxiliary sand-discharging airflow guide pipe 20;

[0026] The upper side of the three-way pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com