Robot for cable fault detection

A fault detection and robot technology, applied in fault location, detection of faults by conductor type, manipulator, etc., can solve the problems of difficult operation, waste of manpower and time, etc., and achieve the effect of convenient work, improved efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

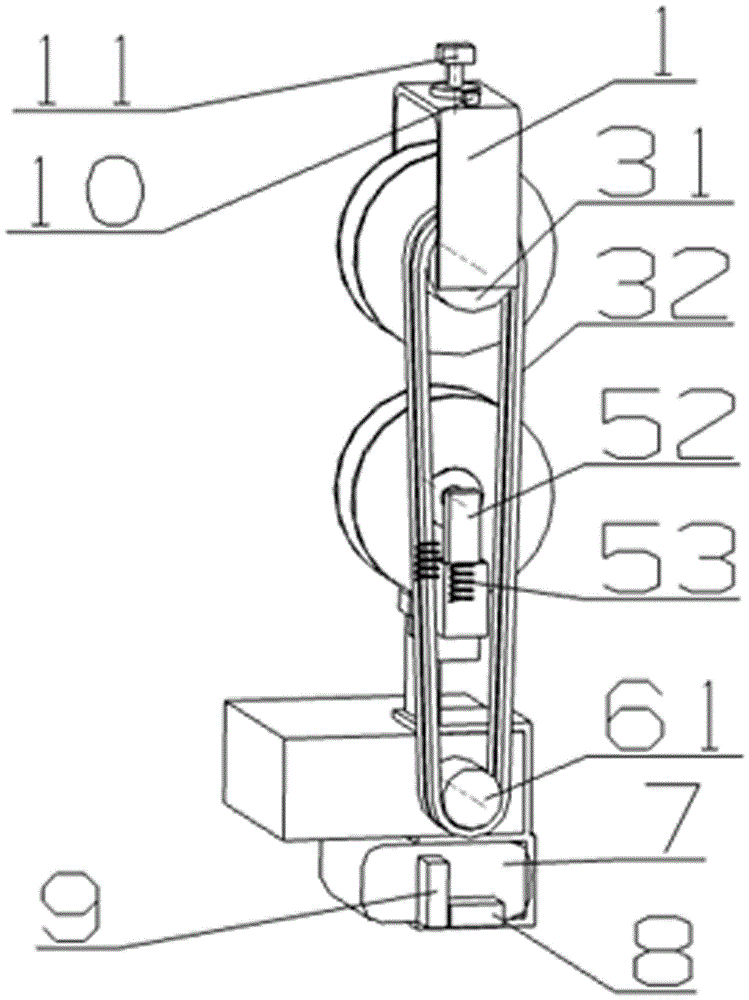

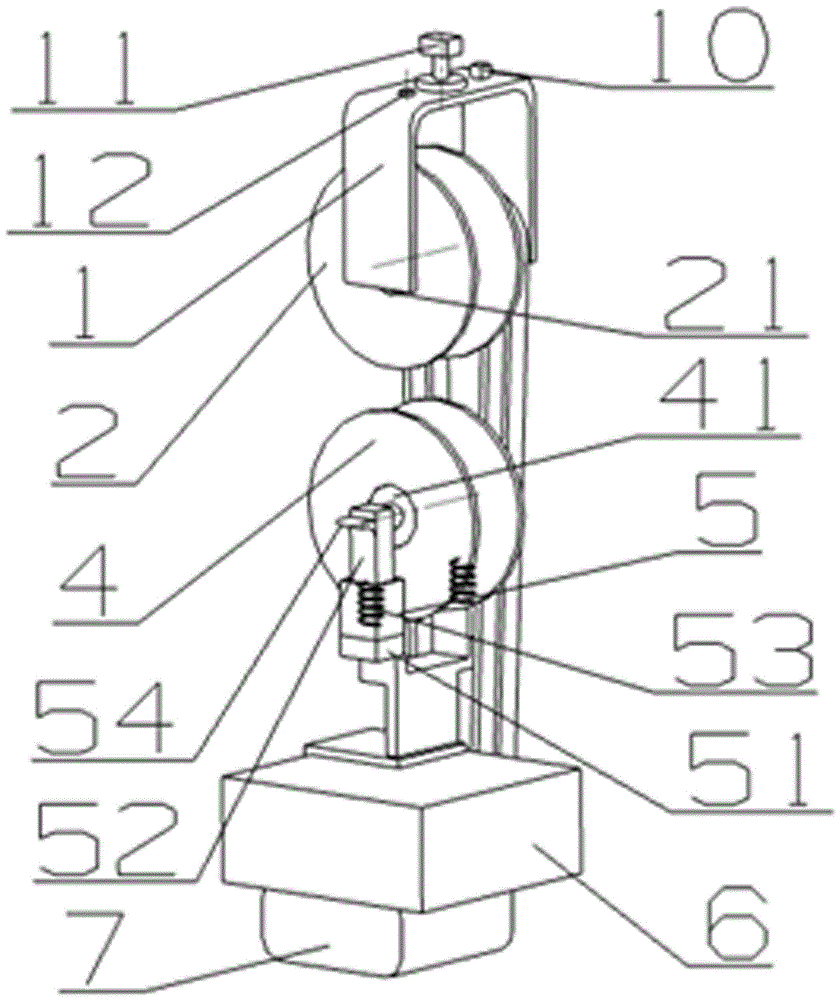

[0020] Combine the following Figure 1 ~ Figure 2 , a preferred embodiment of the present invention is described in detail.

[0021] Such as figure 1 and figure 2 As shown, the robot for cable fault detection provided by the present invention includes: a control module; a drive module, which is connected to the control module through a circuit, and outputs a driving force according to a control signal output by the control module; a clamping module , is fixedly arranged on the driving module; the walking module is arranged above the clamping module, and is connected to the driving module through a transmission, and the walking module cooperates with the clamping module to clamp the cable. The drive module walks or stops along the cable under the action of the driving force output by the driving module; the monitoring module is arranged on the top of the walking module, and monitors the condition of the cable when the walking module walks along the cable.

[0022] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com