Brick making machine with manipulator

A technology of manipulator and brick making machine, which is applied in the direction of manufacturing tools, forming conveyors, ceramic forming machines, etc., can solve the problems of low distribution efficiency, insufficient mixing, and no material turning, and achieve continuous feeding operation, Ensure product quality and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

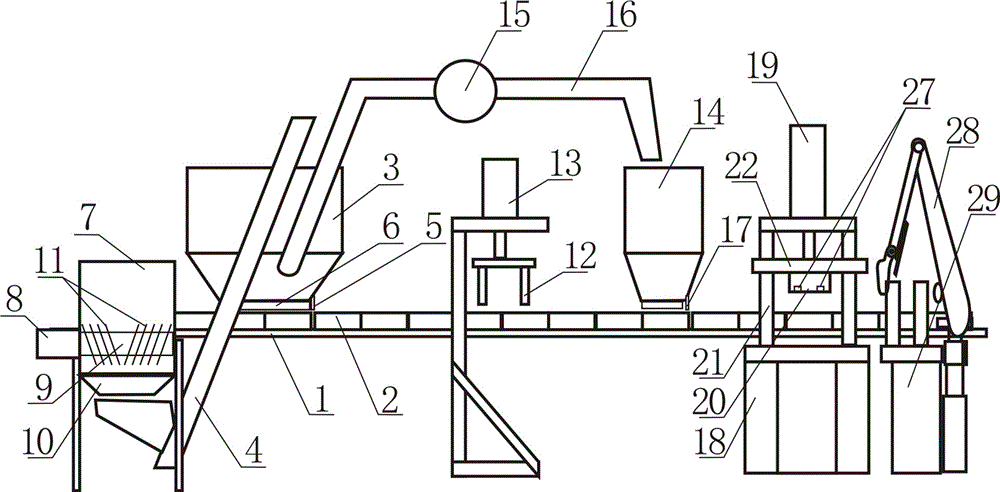

[0022] Such as figure 1 As shown, a brick making machine with a manipulator includes a distributing device. The distributing device includes an intermittent conveyor belt 1, a plurality of brick molds 2, a distributing hopper 3 and a screw feeder 4, and a plurality of brick molds 2 are arranged side by side On the intermittent conveyor belt 1, there is no gap between adjacent brick molds 2, and the cloth hopper 3 is set above the brick mold 2. The gap between the lower port of the cloth hopper and the brick mold is less than 0.5mm, which reduces the brick material The screw feeder 4 sends the brick material into the cloth hopper 3, the intermittent conveyor belt 1 travels to the right, and a scraper 5 is provided on the right side wall of the lower port of the cloth hopper 3. The scraper 5 is used to smooth the bricks in the brick mold 2.

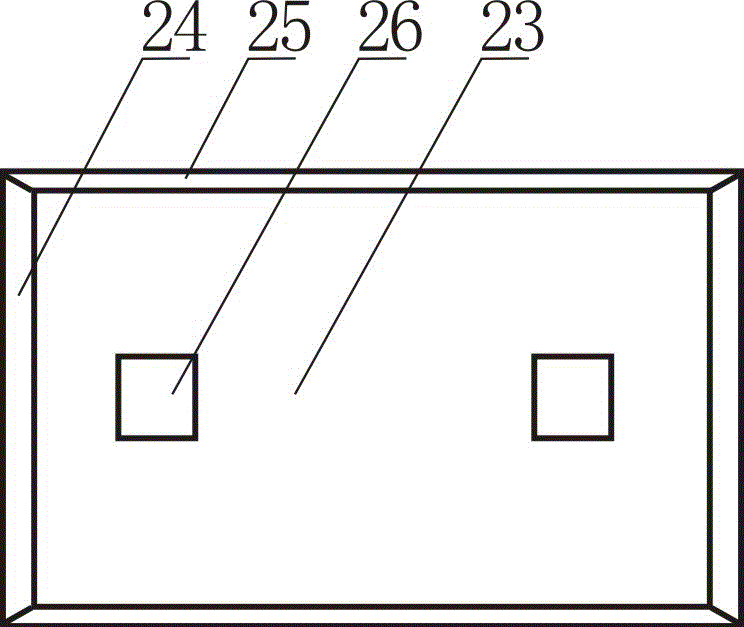

[0023] The two sides parallel to the sides of the intermittent conveyor belt in the lower port of the cloth hopper 3 are provided with soft r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com