Short fiber radial orientation reinforced annular tread extrusion molding and prevulcanization integrated device

A pre-vulcanized, short fiber technology, applied in tires, household appliances, other household appliances, etc., can solve the problems of high manufacturing cost, high processing accuracy requirements of radial orientation head, and can not be applied to large-scale industrial production, etc. Simple structure, small size of the device, and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

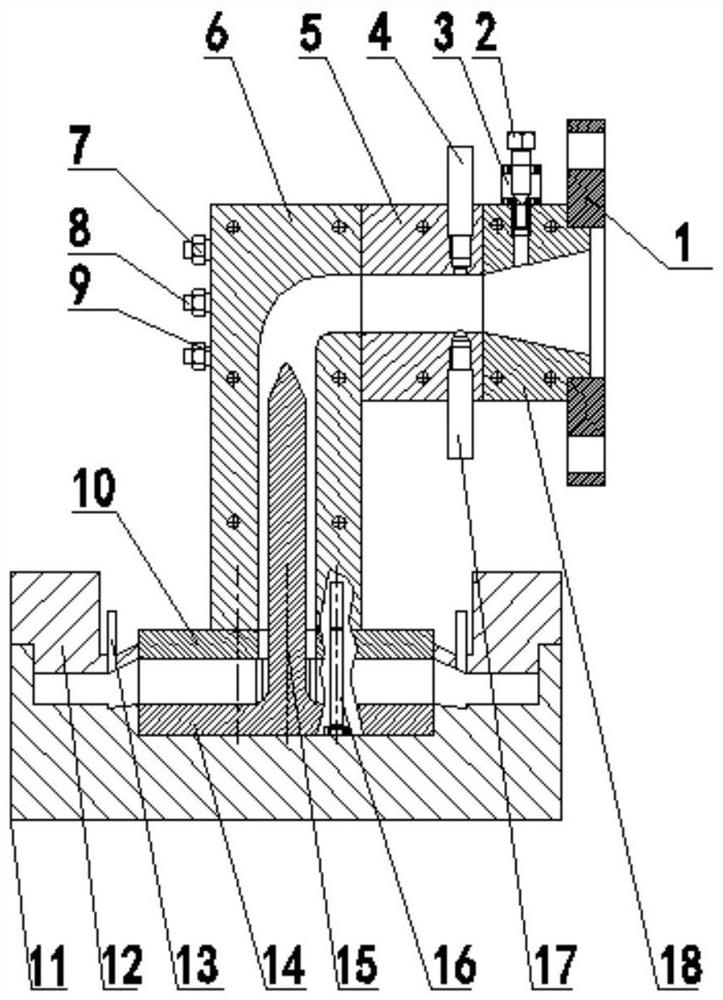

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

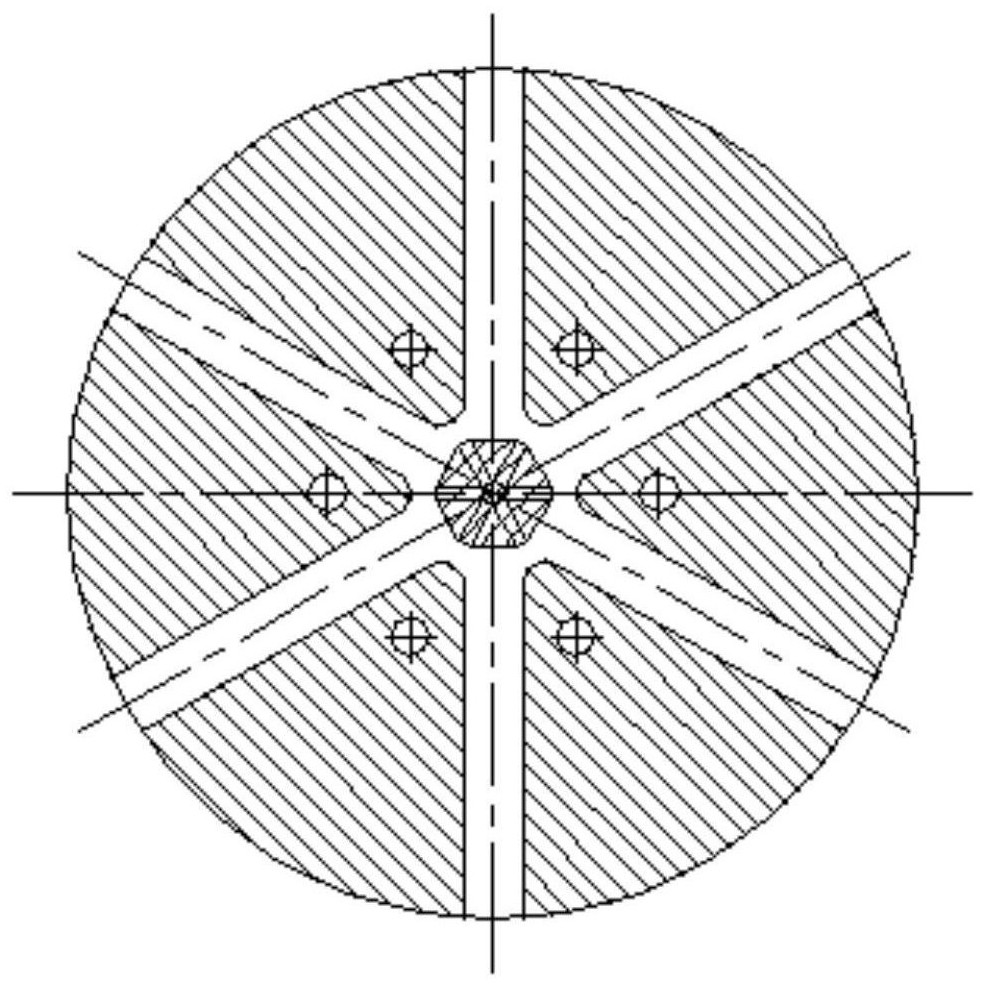

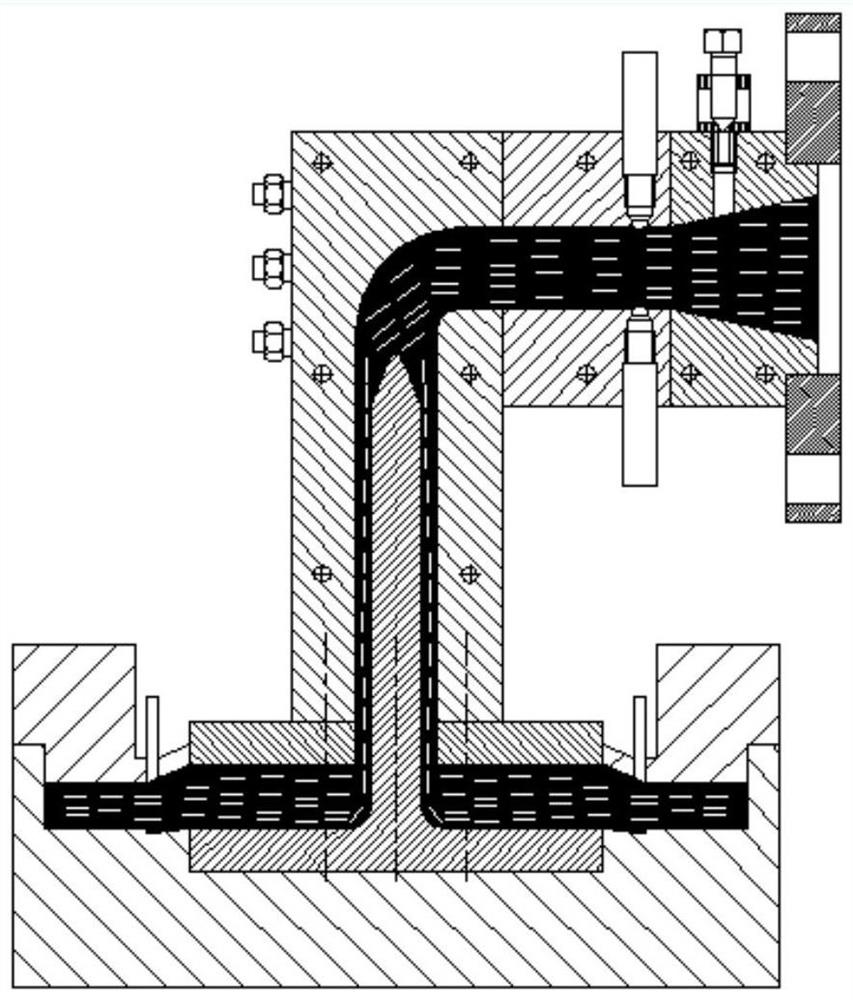

[0025] like figure 1As shown, the present invention provides a short fiber radially oriented reinforced annular tread extrusion molding and pre-vulcanization integrated device, including an inlet section 18, a transition section 5, a split section 6, and a shaping section, and the end of the transition section 5 is connected to the split section 15. The cylindrical flow channel in the splitting section 6 is first deformed by 90 degrees, and a splitting column 15 with a hexagonal cross section is arranged in the deformed splitting section flow channel. The splitting column 15 is fixed in the center of the shaping section, and the shaping section passes through the hexagonal stud. It is connected to the splitting section 6, the splitting column 15 and the central part of the shaping section smoothly transition, and the end of the splitting column 15 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com