Tank truck fluid container adjusting device for reducing cross swaying of fluid and control method thereof

A technology for adjusting devices and control methods, which is applied to oil tank trucks, motor vehicles, and vehicles used for freight transportation, etc., and can solve problems affecting the handling stability of liquid tank trucks, reducing service life, and rollover of liquid tank trucks, so as to improve driving Stability, convenient manufacturing and maintenance, and small changes to the original car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0056] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

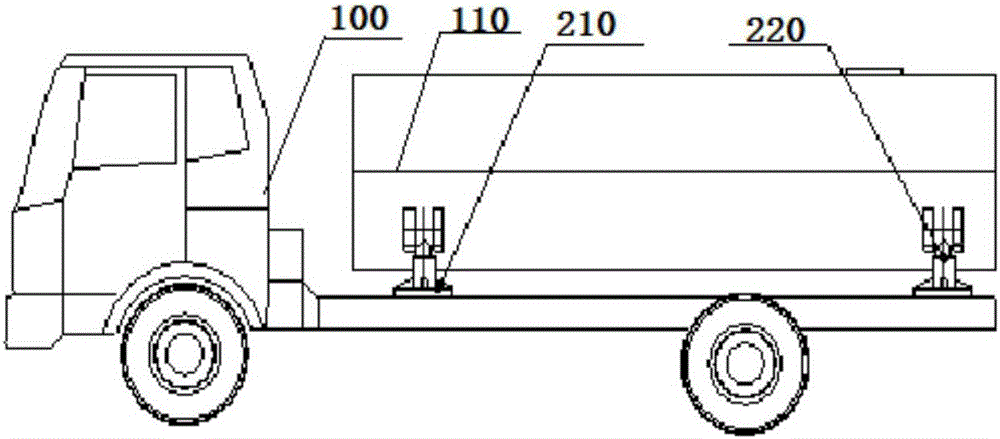

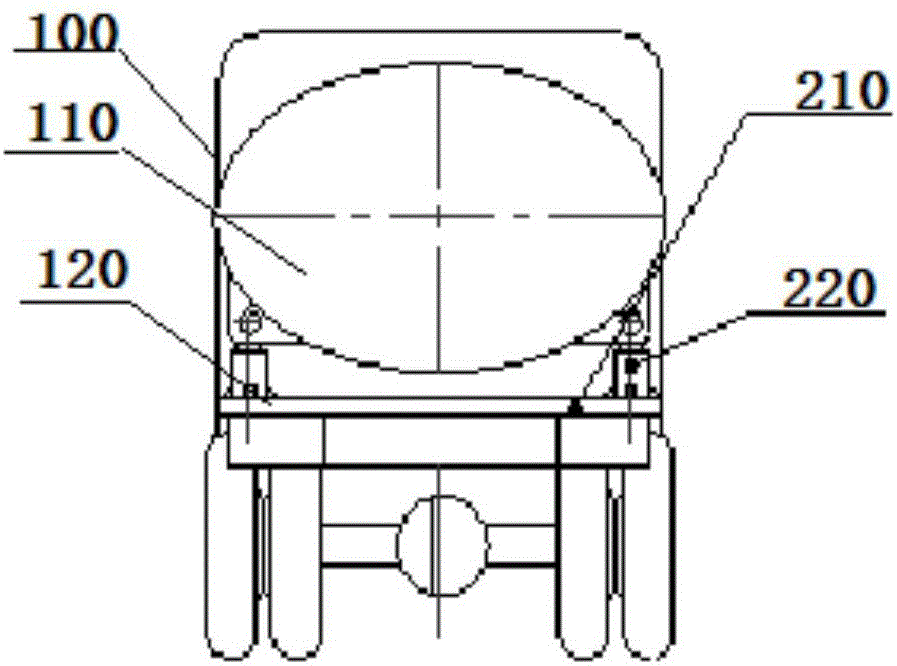

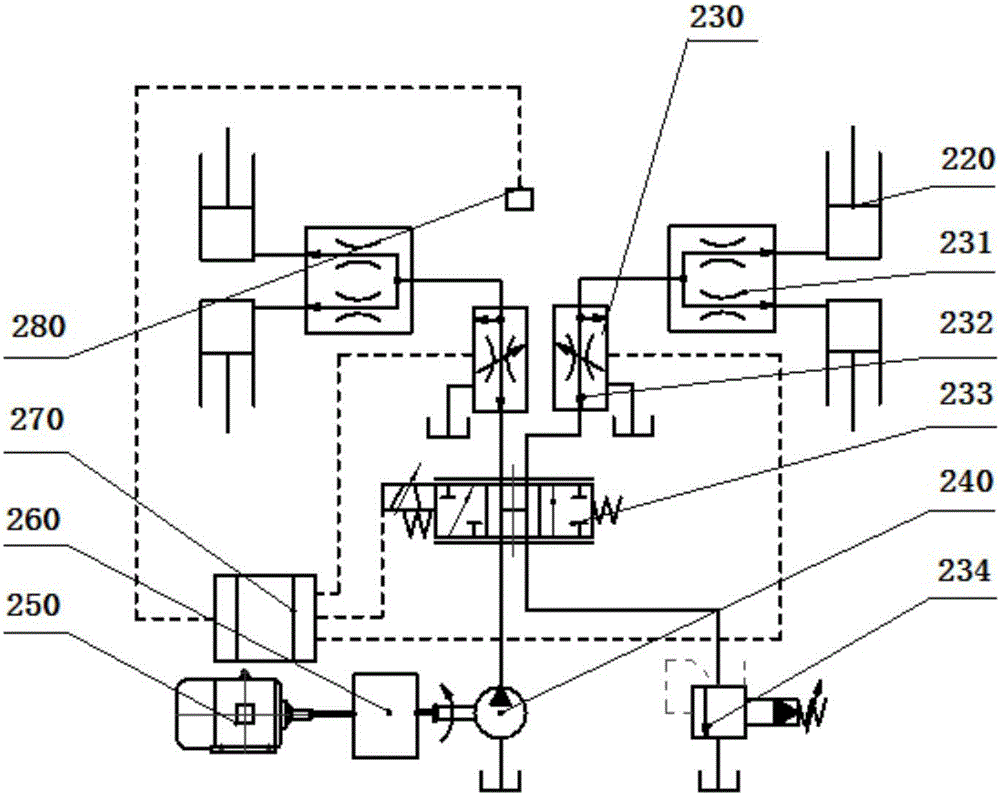

[0057] Figure 1-2 It shows an implementation form according to the present invention, a liquid tank adjustment device for reducing liquid lateral sloshing includes: a liquid tank truck 100 and an adjustment device 200, wherein the liquid tank truck 100 includes a liquid tank 110, a vehicle body 120 , the liquid tank 110 is hinged on the vehicle body 120 through the adjustment device 200, and can tilt laterally relative to the vehicle body 120; the adjustment device 200 includes a liquid tank adjustment unit, a controller 270 and a roll angle sensor 280, and the liquid tank adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com