Liner treading single-wheel direct-drive tooth ring center wheel fixing transmission

A technology of transmission and planetary transmission, which is applied in the direction of vehicle transmission, wheel transmission, transportation and packaging, etc. It can solve the problems of difficulty in maintaining the transmission and the inability to realize automatic shifting, etc., and achieve lower requirements, compact structure, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

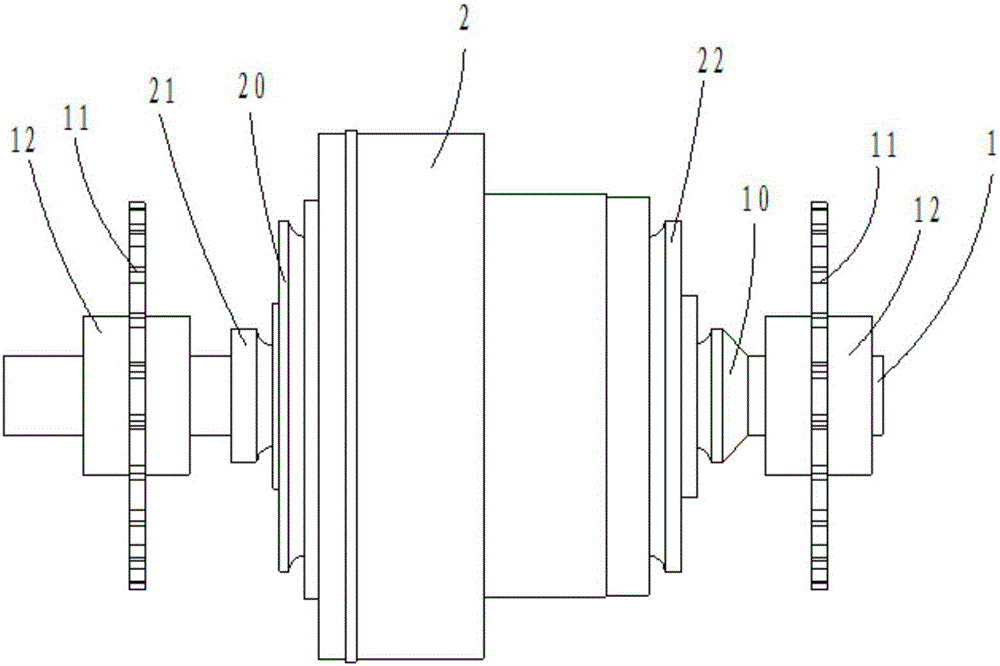

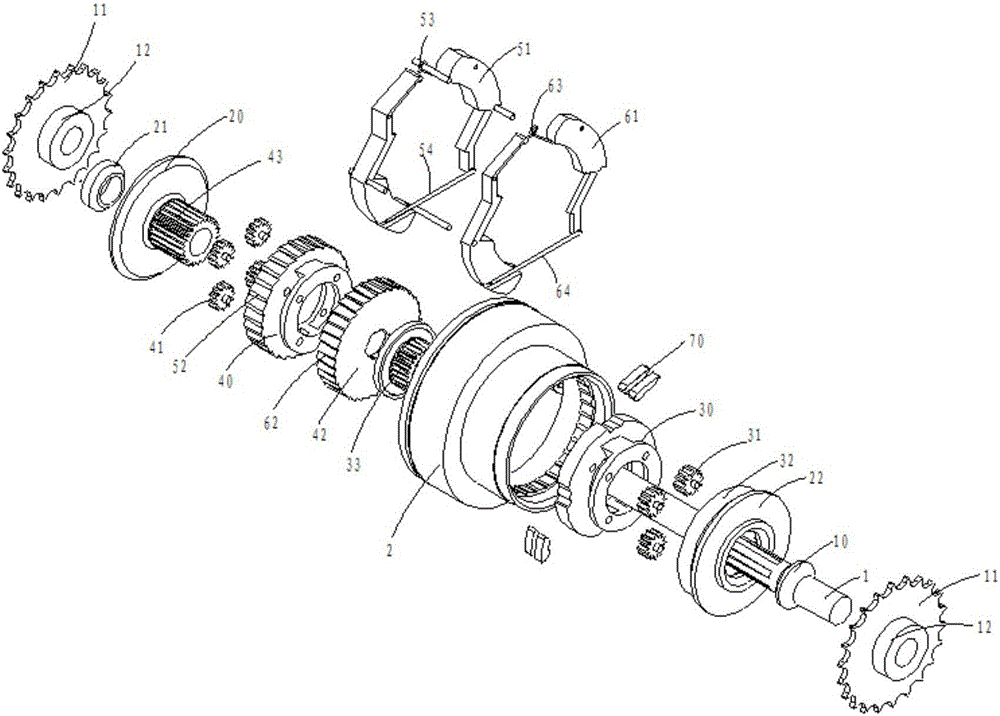

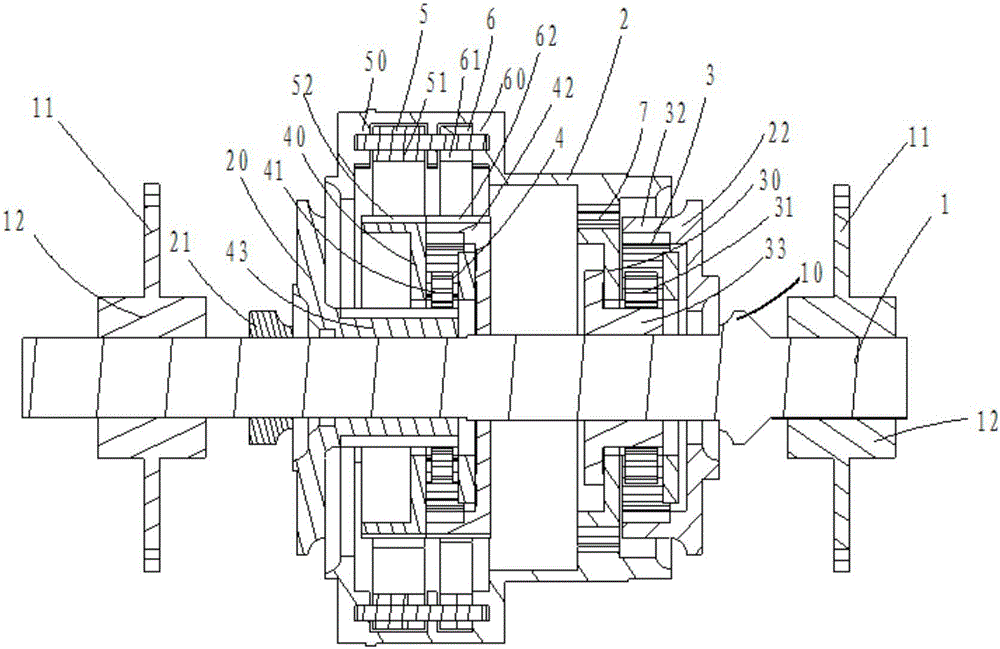

[0024] ginseng Figure 1 to Figure 5 As shown, a straight-line pedaling single-wheel direct-drive ring gear center wheel fixed transmission includes: a central shaft 1, a hub 2 and a speed change mechanism arranged between the central shaft 1 and the hub 2, and the two ends of the central shaft 1 are arranged There is an input wheel 11, and a first overrunning clutch 12 is arranged between the input wheel 11 and the central shaft 1. In this embodiment, the input wheel 11 and the first overrunning clutch 12 form an assembly, and the central shaft 1 is a power input part, the hub 2 is a power output part, and the transmission mechanism includes two sets of planetary transmissions (the first planetary transmission 3 and the second planetary transmission 4) and two sets of automatic centrifugal shifting mechanisms (the first automatic centrifugal Shift mechanism 5 and the second automatic centrifugal shift mechanism 6).

[0025] The first planetary transmission 3 and the second p...

Embodiment 2

[0031] The rest of the structure of the straight-line pedaling single-wheel direct-drive ring gear fixed gear transmission in this embodiment is the same as that of the straight-line pedaling single-wheel direct-drive transmission in Embodiment 1, the difference is that in Embodiment 1, the central shaft The second ring gear is fixedly connected, and in Embodiment 2, the central shaft is fixedly connected with the second planet carrier.

[0032] The working principle of the straight-line stepping single-wheel direct-drive ring gear center wheel fixed transmission in this embodiment is as follows: the straight-line stepping single-wheel direct drive ring gear center wheel fixed transmission in this embodiment realizes three-stage speed change in total. The first step in this embodiment The second overrunning clutch is in the normally open state, that is, the first planetary carrier and the wheel hub are always in the meshing state. In low gear, the power is input from the centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com