Floating ring oil distributor

A technology of oil distributor and floating ring, which is applied in the direction of ship propulsion, ship parts, ships, etc. It can solve the problems affecting the formation of oil film, affecting the working performance and service life of the oil distributor, and free floating, so as to improve the working performance and use The effect of life and improving the efficiency of hydraulic oil distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

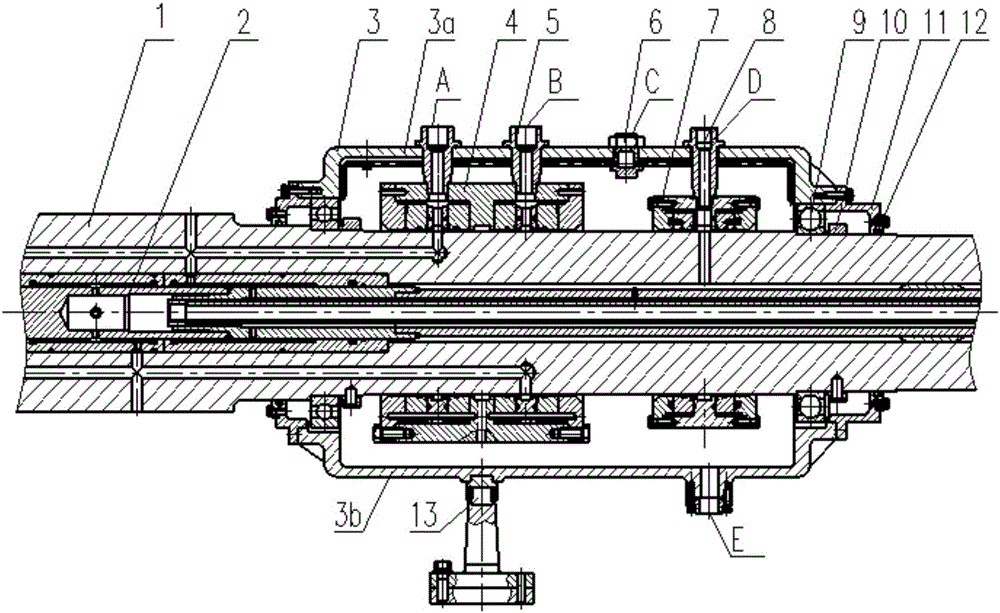

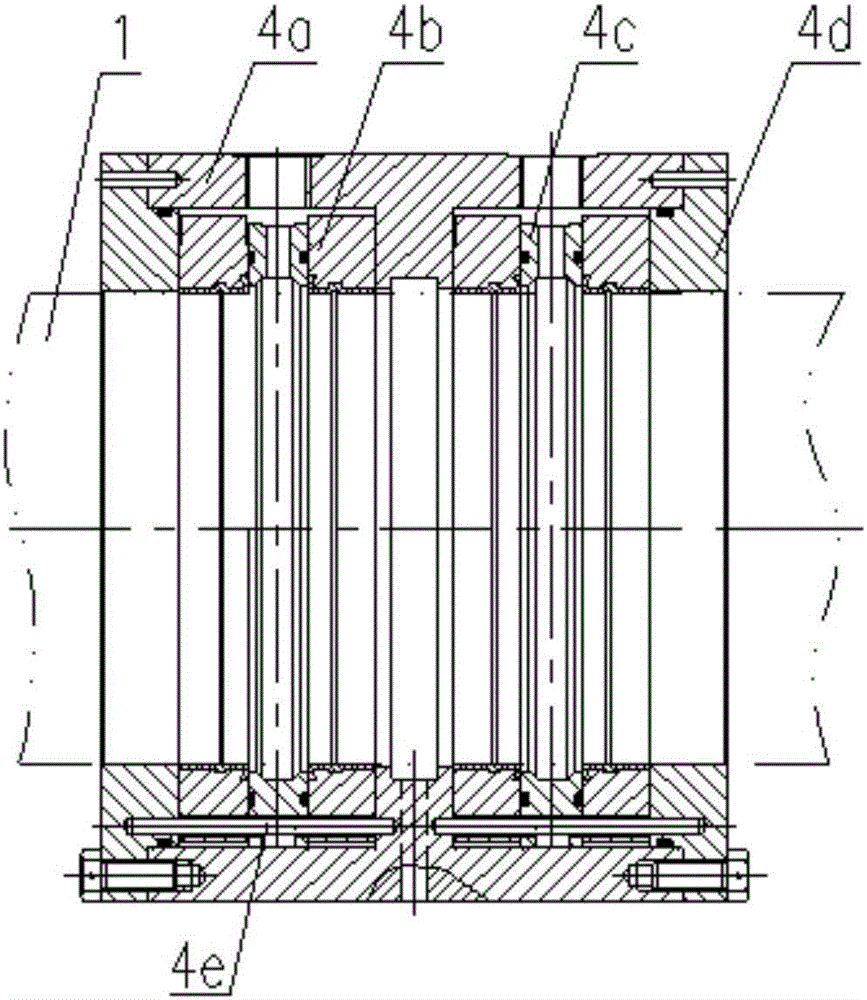

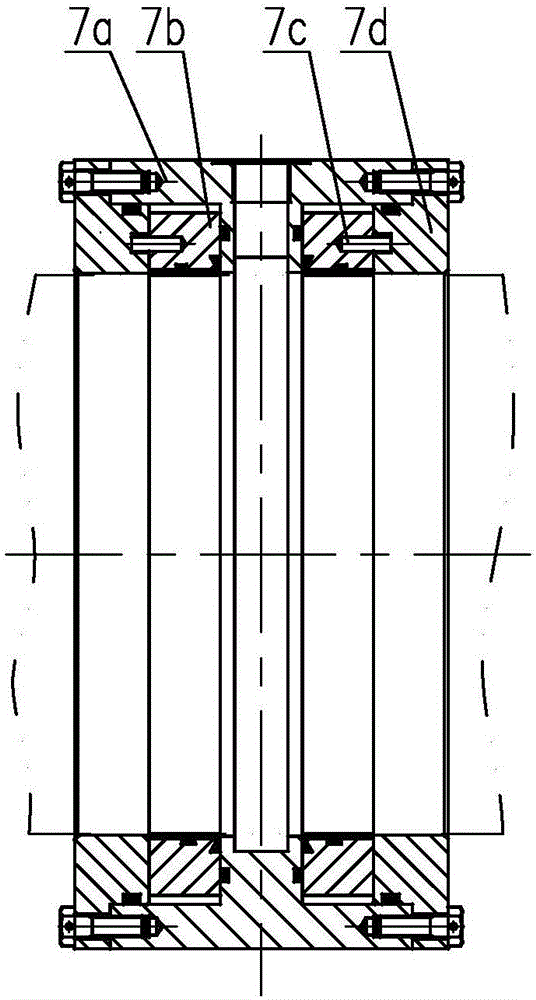

[0015] as attached figure 1 As shown, a floating ring oil distributor includes a hollow oil distribution shaft 1, a double oil pipe 2 with double oil passages, a set of split tanks 3, and a set of adjustable distance rotary seal components 4. Two adjustable distance oil circuit joint bodies 5. One set of cooling oil circuit assembly 6. One set of static pressure rotary seal assembly 7. Two static pressure oil circuit joint bodies 8. Two rolling bearings 9. Two bearing retaining rings 10 , Two end caps 11, two rotating seals 12, anti-rotation support 13.

[0016] The double oil pipe 2 is inserted into the inner hole of the oil distribution shaft 1 . The split box body 3 is fixedly connected by the upper box body 3a and the lower box body 3b by screws, and is positioned on the oil distribution shaft 1 through the rolling bearing 9 . The rolling bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com