Automatic weighing system for fruits and vegetables

An automatic weighing, fruit and vegetable technology, applied in the direction of packaging fruit/vegetables, packaged food, packaging, etc., can solve the problems of low weighing accuracy, less weighing times, and the inability to continuously weigh a variety of complex materials, etc., to achieve The effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a further understanding of the technical solution and beneficial effects of the present invention, the technical solution of the present invention and its beneficial effects will be described in detail below with reference to the accompanying drawings.

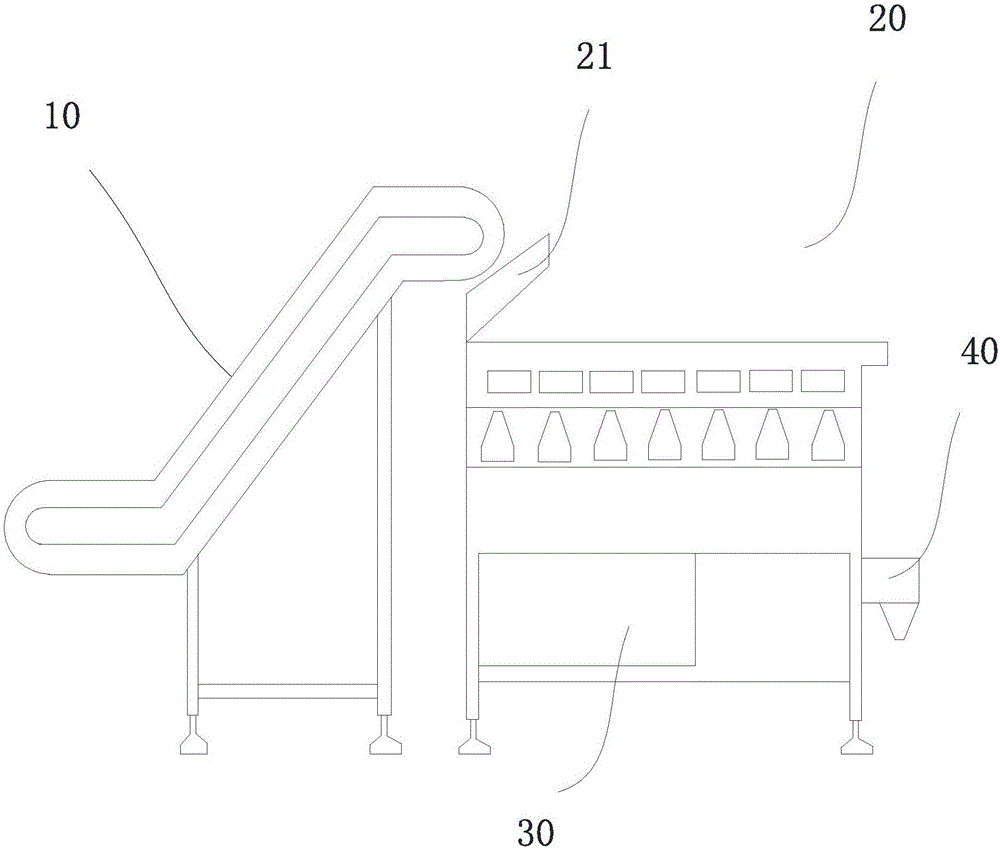

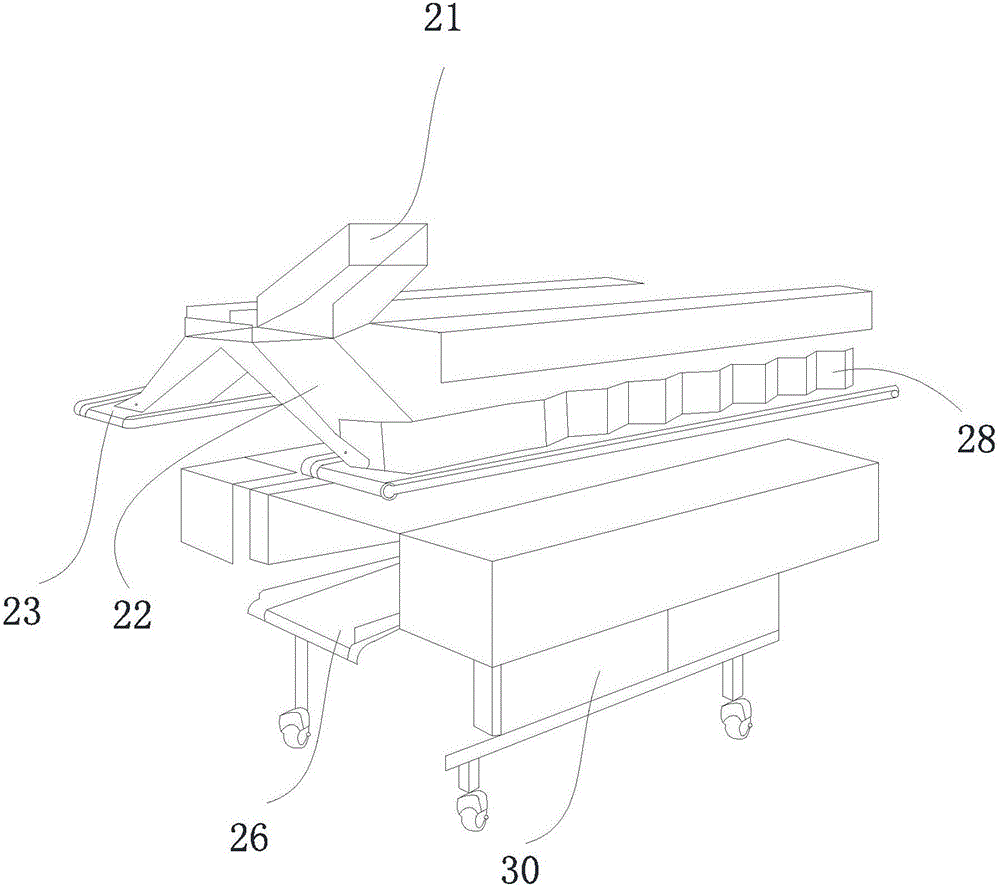

[0045] figure 1 and figure 2 Respectively, the side view schematic diagram and the three-dimensional structure schematic diagram of the present invention, such as Figure 1 to Figure 2 As shown, the present invention provides an automatic weighing system for fruits and vegetables, including a material lifting system 10, an automatic material distribution system 20, a control system 30 and a discharging system 40, wherein the material lifting system 10 includes an inclined The conveyor belt is used to transport the material to be weighed to the automatic material distribution system 20 .

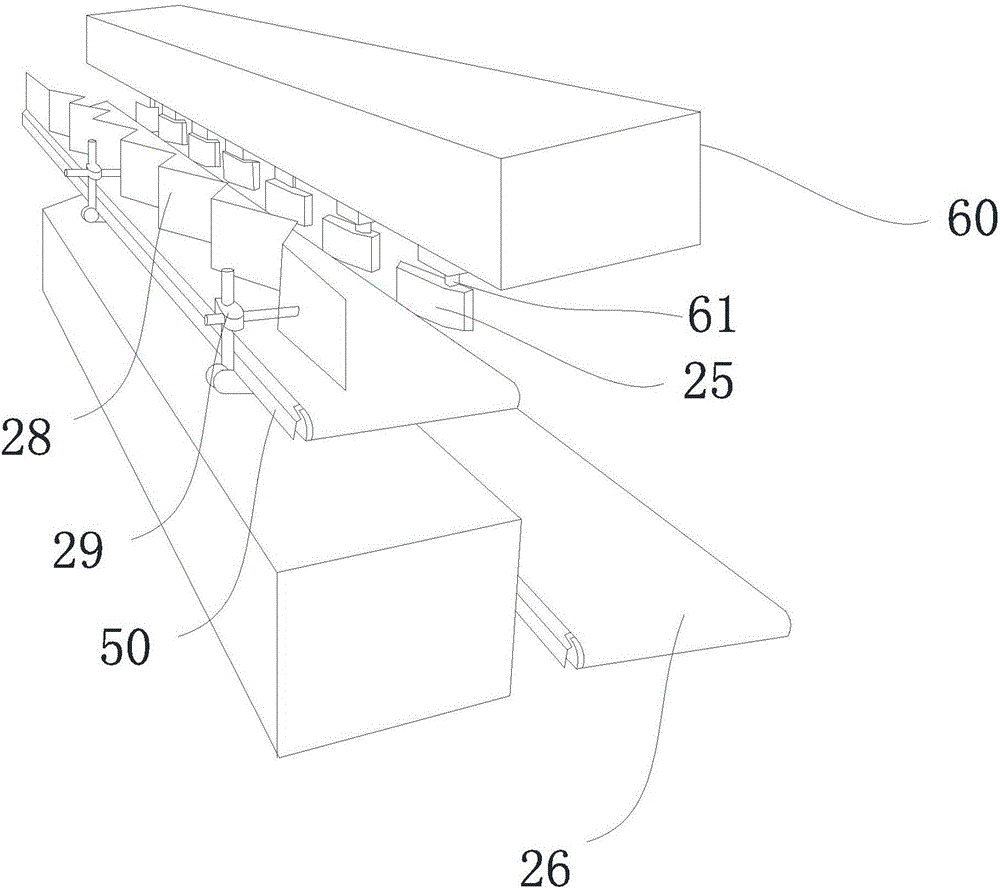

[0046] Please refer to image 3 and Figure 4 As shown, it is respectively a partial structure three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com