Turnover lifting type yardage roll stacking trolley

A technology of flipping, lifting, and cloth rolling, which is applied in the stacking of objects, the unstacking of objects, and the control device of conveyors, etc., which can solve the problems of error accumulation amplification, stacking problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

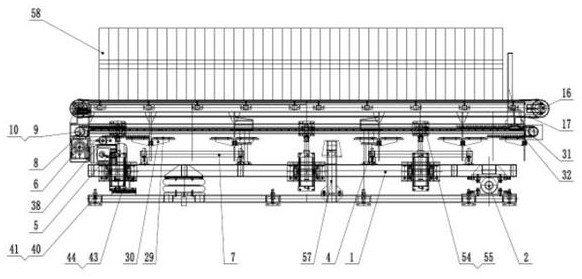

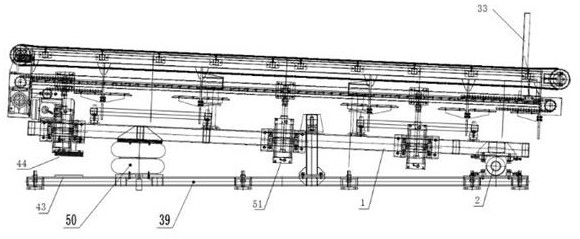

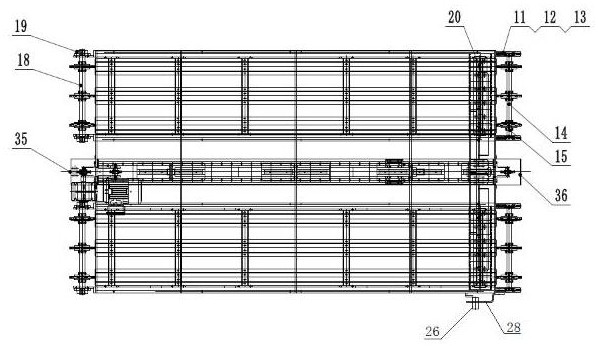

[0043] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

[0044] A flip-up lift-type cloth roll palletizing trolley includes a car frame 1 and a turning frame 37 rotatably connected with the car frame 1. Specifically, the car frame 1 and the turning frame 37 are connected by a rotating shaft 7, and the belt seat is turned left and right. The bearing 4 is bolted to the vehicle frame, and the other end of the bearing 4 with a left and right flipping seat is transitionally matched with the rotating shaft 7 of the flipping frame 37 to realize the flipping and receiving function of the flipping frame 37 and the vehicle frame 1 .

[0045] A first driving device for controlling the rotation of the turning frame 37 is installed between the frame 1 and one side of the turning frame 37. In this embodiment, the first driving device is a turning cylinder 51, and the turning cylinder 51 pushes out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com