Three-degree-of-freedom mechanical arm device and manipulator platform system

A robotic arm and degree-of-freedom technology, applied in conveyor objects, transportation and packaging, etc., can solve the problems of reducing experimental accuracy, human operation errors, and the inability to guarantee the accuracy and uniformity of the experimental process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

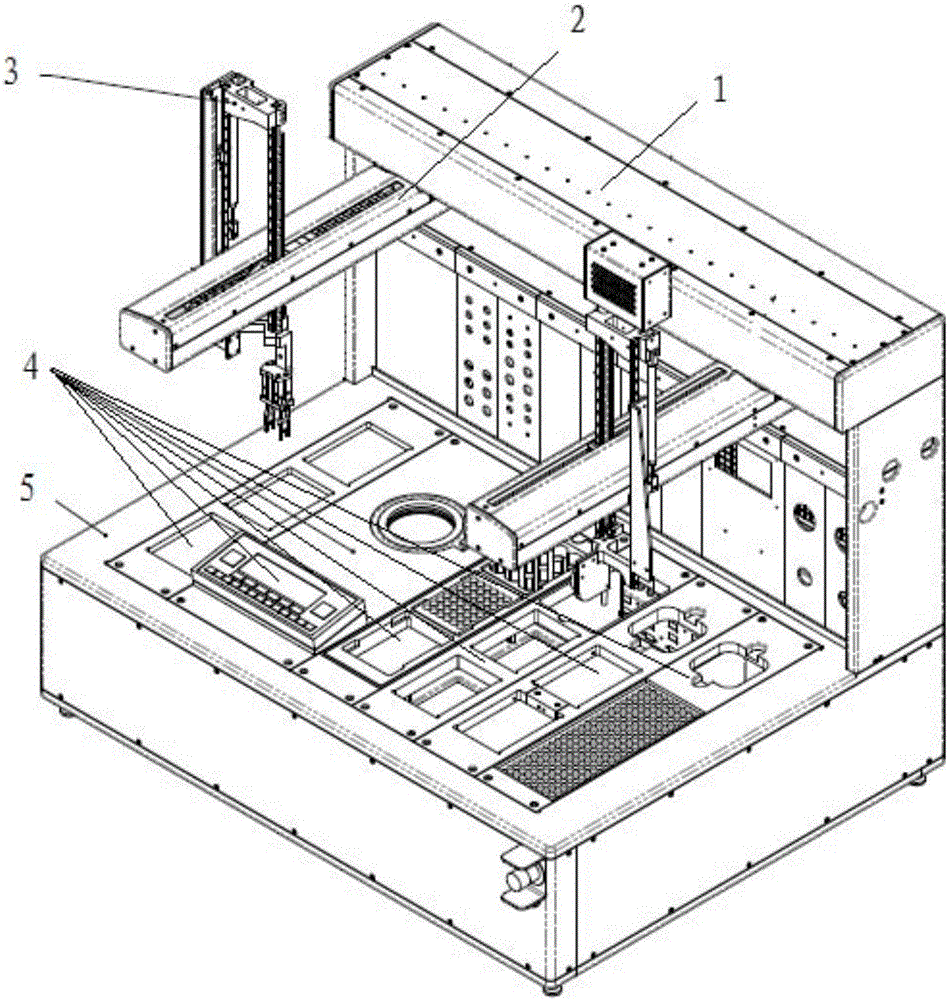

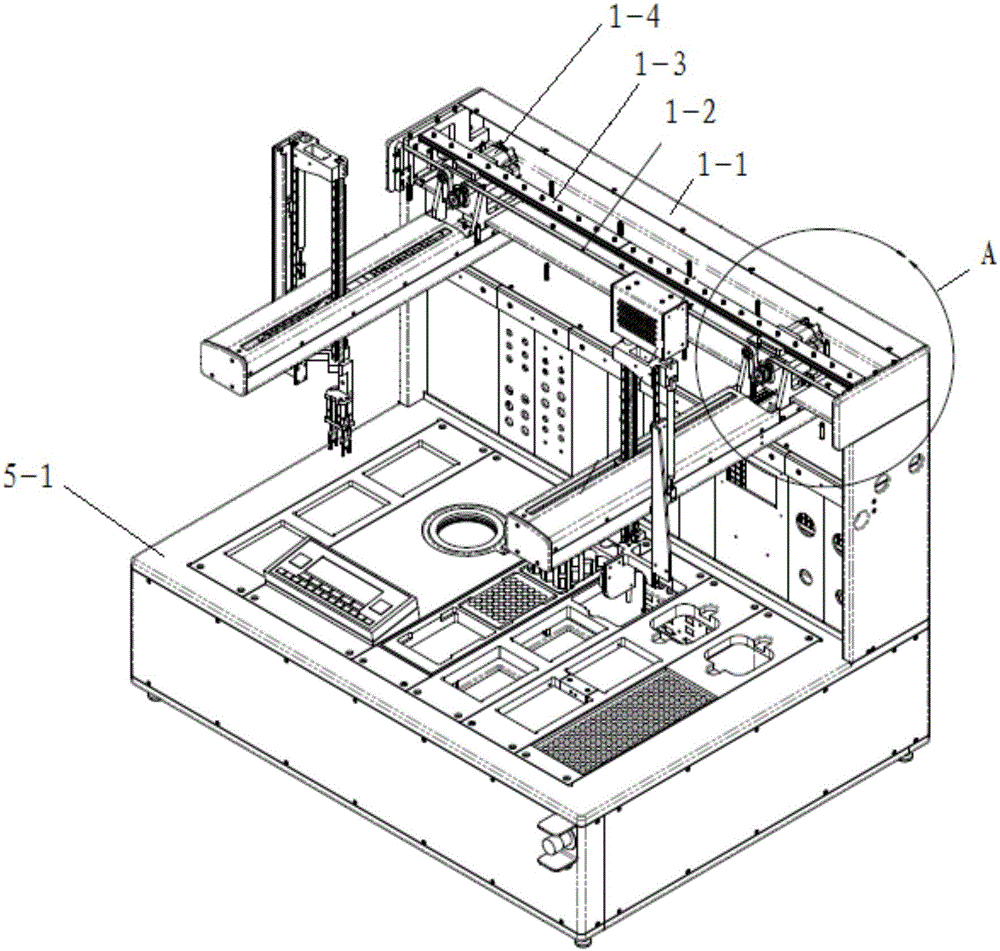

[0023] see Figure 2-6 , A three-degree-of-freedom mechanical arm device provided by an embodiment of the present invention includes: an X-axis mechanism 1 , several Y-axis mechanisms 2 and several Z-axis mechanisms 3 .

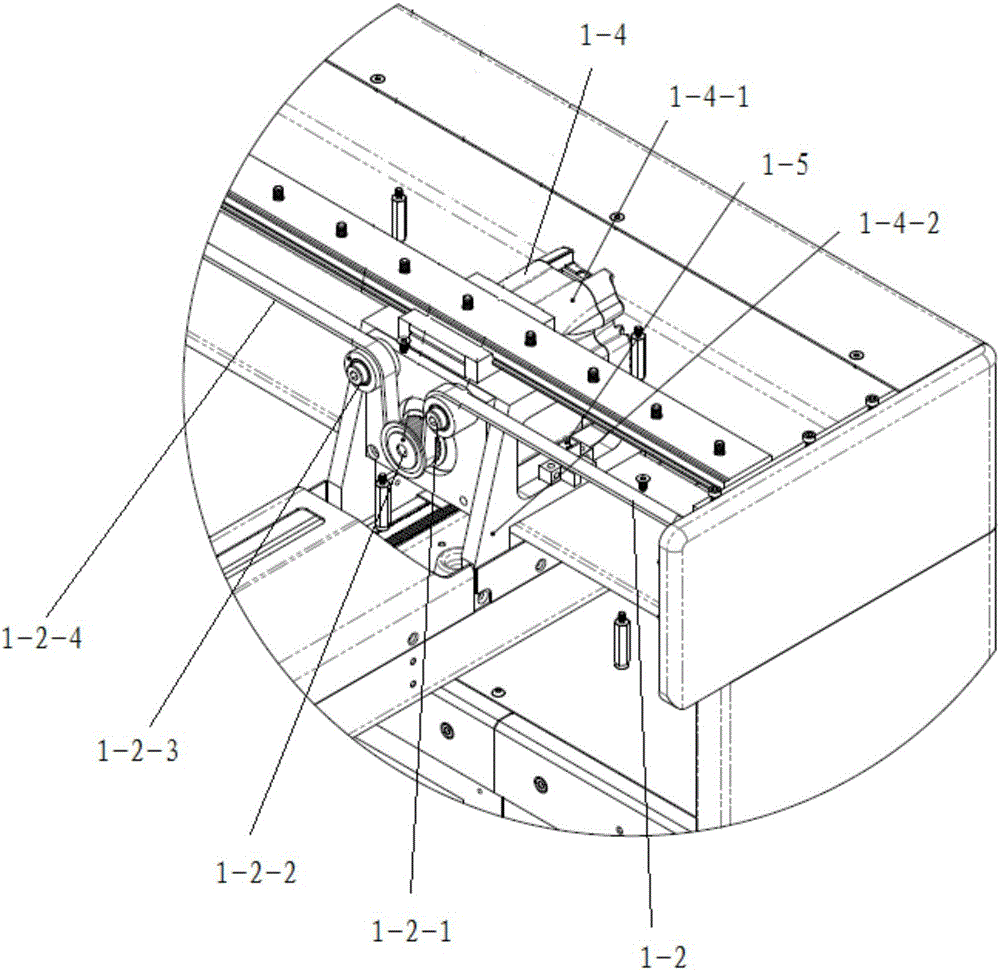

[0024] The X-axis mechanism 1 includes: a support frame 1-1, a first transmission part 1-2, an X-axis guide rail 1-3 and a plurality of X-axis driving parts 1-4, and the X-axis guide rail 1-3 and the support frame 1-1, the several X-axis drive parts 1-4 are movably arranged on the X-axis guide rail 1-3, one end of the first transmission part 1-2 is connected to one end of the support frame 1-1, The other end is connected to the other end of the support frame 1-1 through the plurality of X-axis drive components 1-4;

[0025] The several Y-axis mechanisms 2 include: a support arm 2-1, a Y-axis guide rail 2-2, a Y-axis driving part 2-8 and a second transmission part 2-3, and the support arm 2-1 and the several X The shaft driving part 1-4 is connected, the Y-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com