On-line automatic photographic film storage speed setting device, system and method

A storage device and film technology, applied in the directions of transportation and packaging, winding strips, sending objects, etc. It solves the problems of the production line taking up the full roll and cutting, and failing to meet the time required for wide-format film cutting, achieving a high degree of automation, overcoming the stretching phenomenon, and increasing the storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

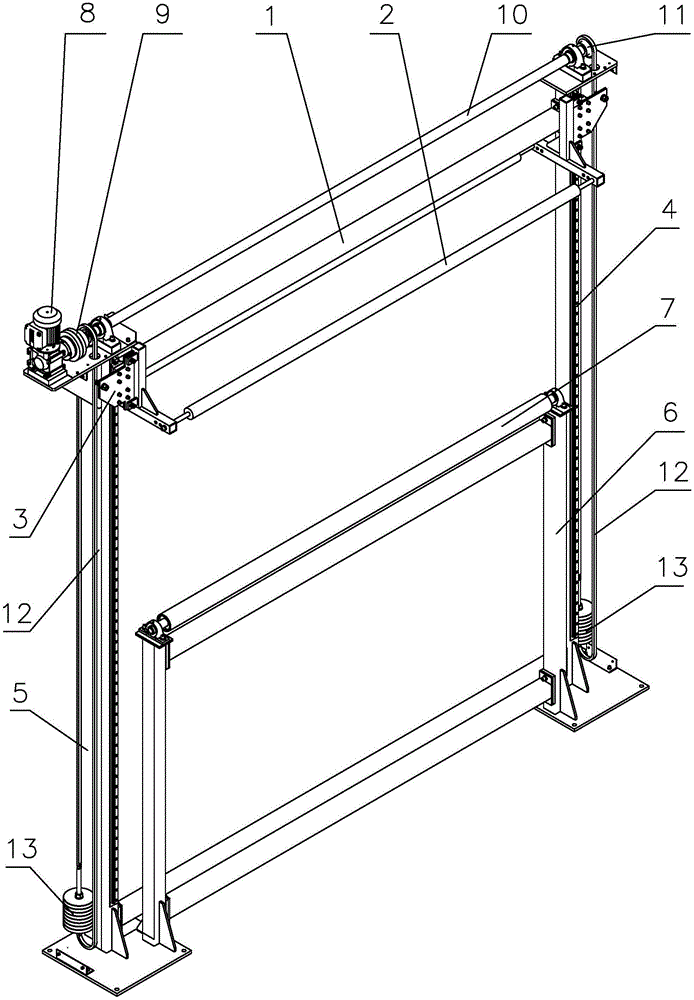

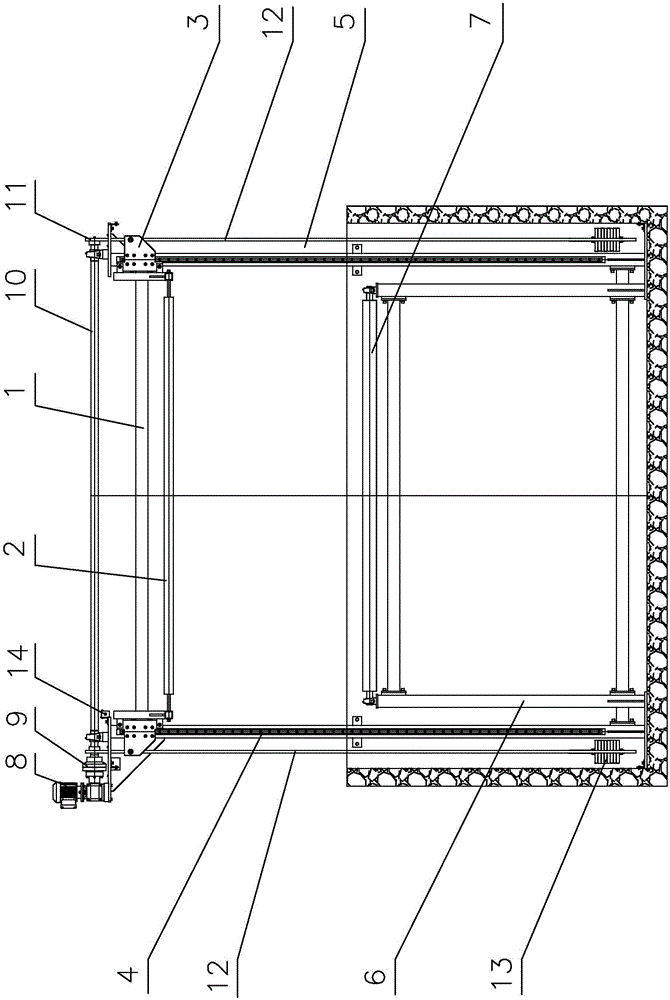

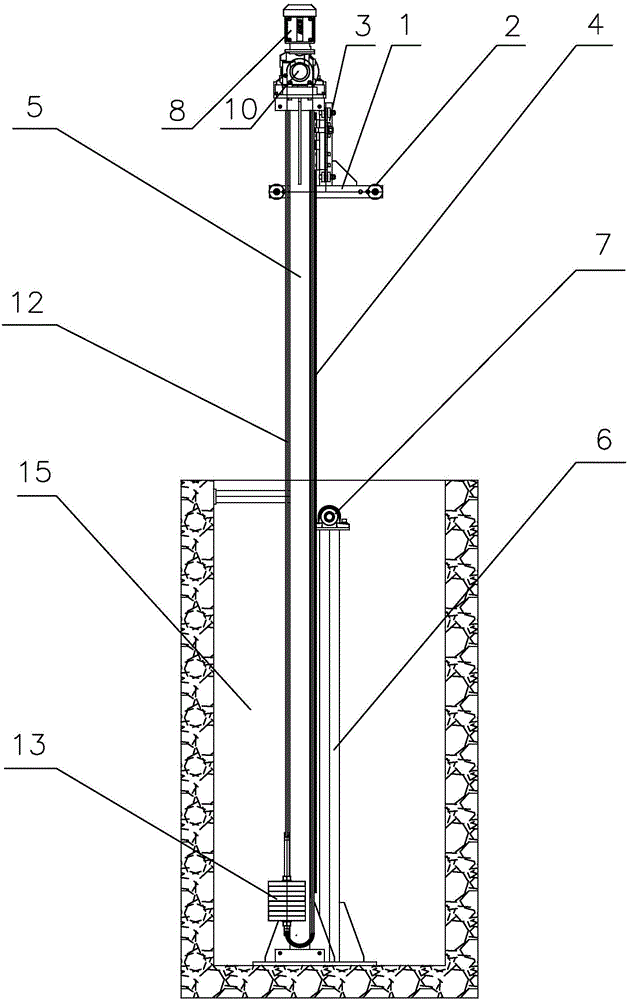

[0047] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0048] The film storage device of the present invention includes a floating double-pressure roller assembly based on the frame 5, a sliding mechanism and a floating mechanism, and a fixed roller assembly corresponding to the floating double-pressure roller assembly, as shown in Figure 4(a) and Figure 4(b) , Figure 4(c), Figure 4(d).

[0049]The frame 5 is left and right two vertical columns, and the distance between the left and right columns is greater than the width of the film 18; the sliding mechanism includes two linear ball guide rails 4 and two slide seats 3, and the linear ball guide rails 4 are installed vertically on the side of the left and right racks 5 respectively, and the sliding seats 3 are respectively installed in sliding fit on the corresponding positions of the linear ball guide rail 4; the floatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com