Improved cable lead coating method

A technology for cables and cable sheaths, which is applied to equipment for connecting/terminating cables, etc. It can solve the problem of reducing the heating and preheating area and time of lead filling, large heating and preheating area, and low efficiency of staff. problems, to achieve the effect of reducing the technical requirements of lead enamel process, improving quality and avoiding excessive heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

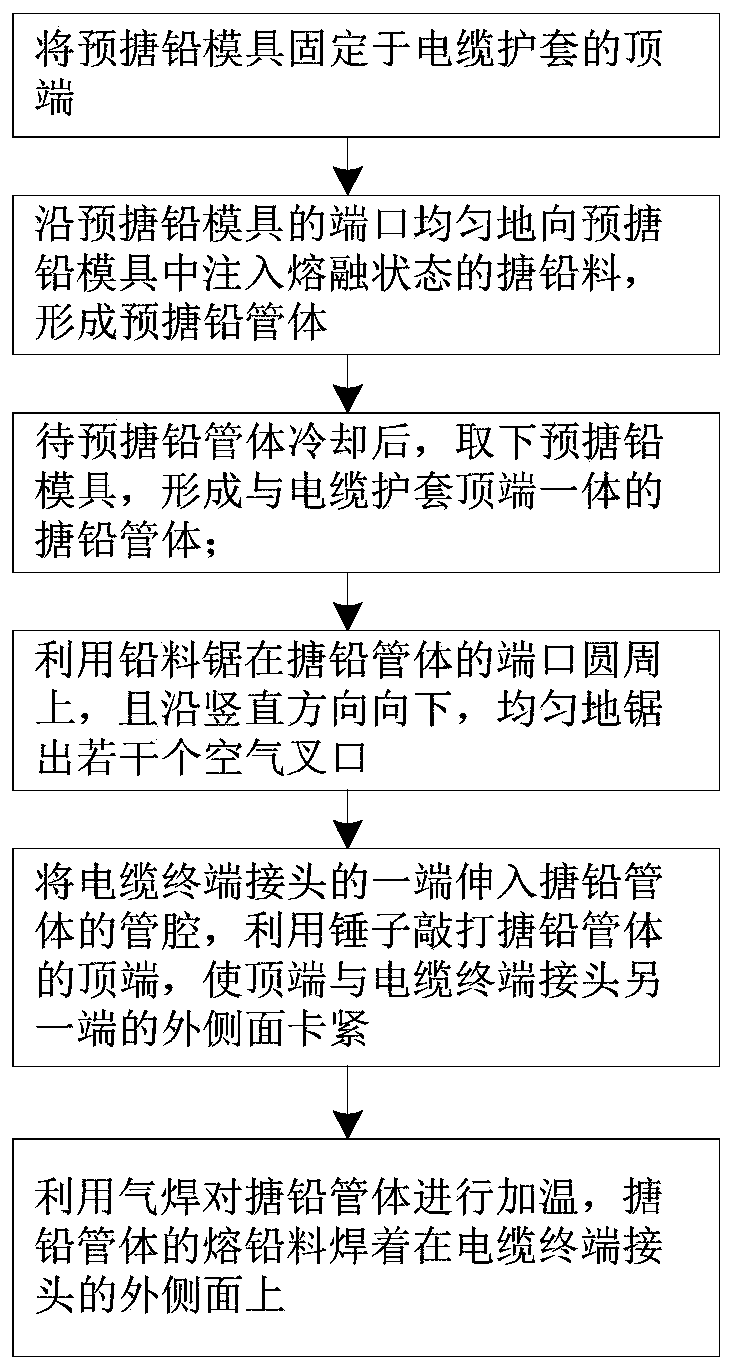

[0037] Such as figure 1 The schematic flow sheet of the improved method for lead enamel proposed by the present invention shown, a kind of improved method for cable enamel lead, comprises the following steps:

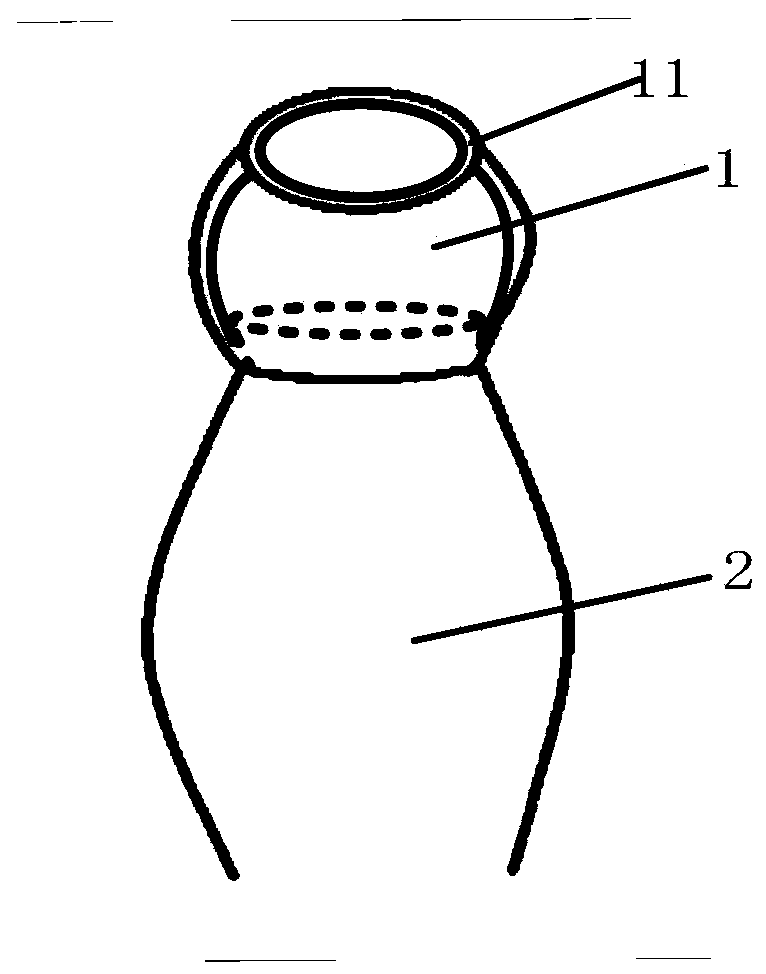

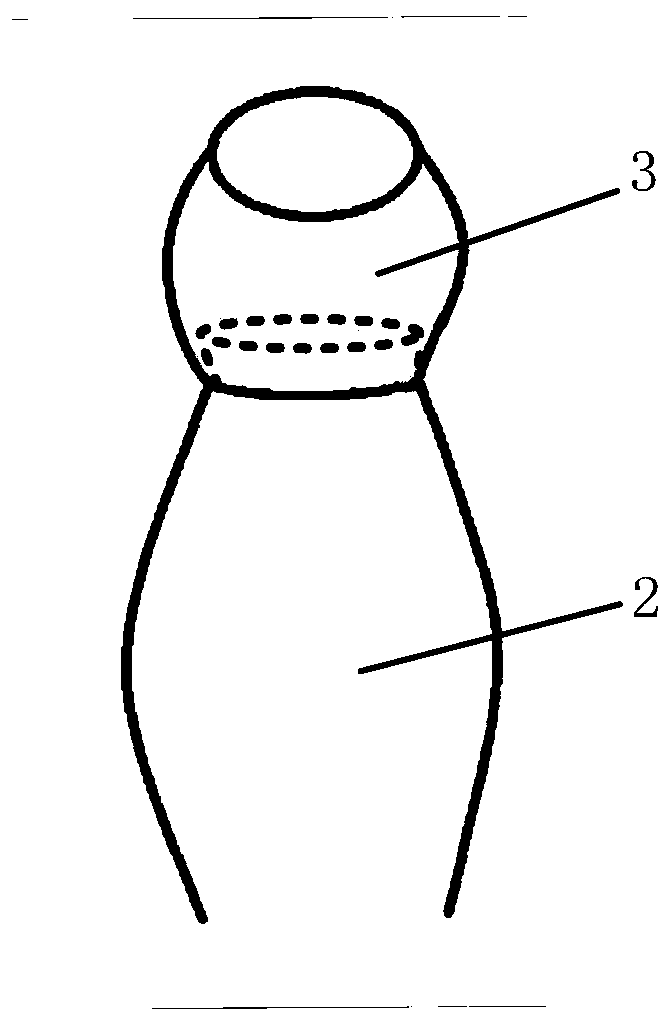

[0038] S1. Fix the lead-filled mold 1 on the top of the cable sheath, and the structure diagram of the lead-filled mold 1 fixed on the top of the cable sheath 2 is as follows figure 2 As shown, the lead-filled mold 1 is in the shape of a tube with a thick middle and thin ends, which facilitates the insertion of one end of the middle joint of the cable into the cavity of the subsequently formed lead-filled pipe body, and further facilitates the welding of the heated lead-filled pipe body. On the middle joint of the cable, the thick shape in the middle facilitates the subsequent deformation and relaxation of the lead-filled pipe body after being heated.

[0039] S2. Inject the lead-filling material in molten state into the lead-filling mold 1 at a constant speed along t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com