Pipe network layer line combining and winding machine

A coiling machine and mesh layer technology, applied in the field of pipe mesh layer line winding machine, can solve the problems of time-consuming and affecting production efficiency, and achieve the effect of reducing production time-consuming and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

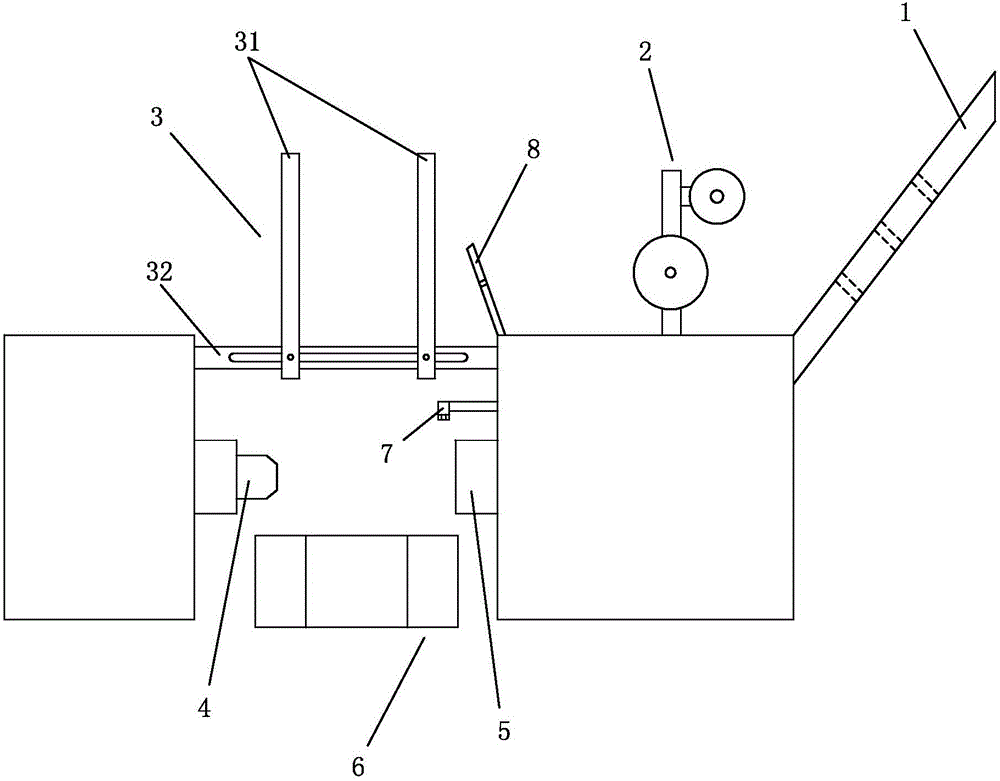

[0011] refer to figure 1 , a kind of pipe mesh layer wire closing coiler of the present invention, comprises the wire lifting frame 1 on the body, the wire closing wheel 2, the bobbin holder 3, the telescopic ejector pin 4, the rotating seat 5 and the doffing track 6, and Along the movable lead frame 7, the telescopic ejector rod 4 is horizontally opposite to the rotating seat 5, and the rotating seat 5 is driven by a motor. Above, the doffing track 6 is arranged under the telescopic jack rod 4 and the rotating seat 5, the wire lifting frame 1 and the wire closing wheel 2 are arranged on the side of the wire bobbin frame 3, and the wire lifting frame 1 is installed obliquely and is provided with a The corner passes through the guide hole of the mesh layer wire, and the raw material coil of the mesh layer wire can be fixed vertically or horizontally. Pushed by the movable lead frame 7, it can reciprocate along the axial direction of the telescopic ejector rod 4 or the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com