Method for preparing high-quality indigo slurry based on lactic acid bacterium fermentation

A lactic acid bacteria fermentation, high-quality technology, applied in the field of indigo dyeing, can solve the problems of insufficient release of indoside, lack of dominance, long time consumption, etc., to achieve the effects of improving release rate, improving production quality and reducing production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

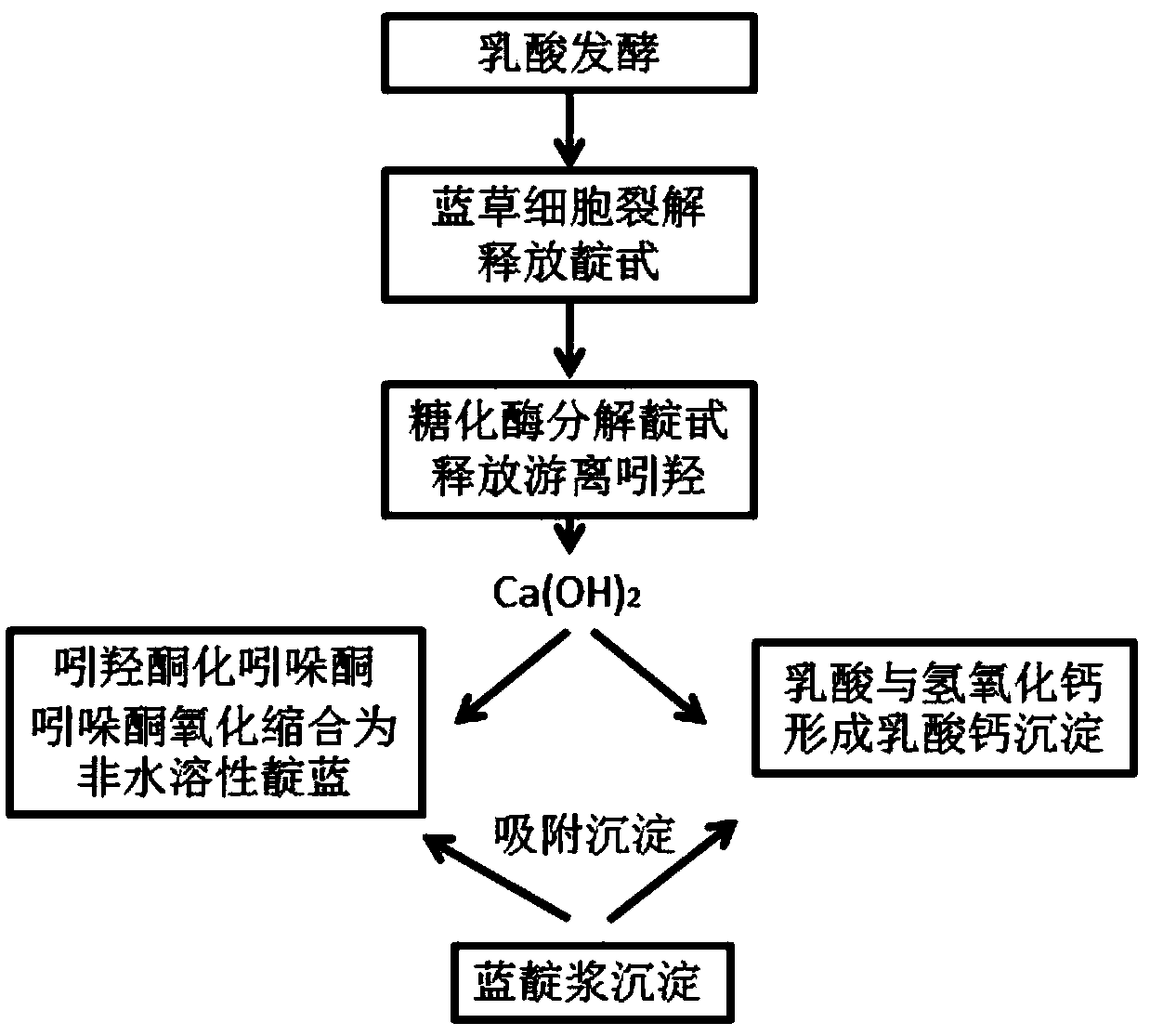

[0034] This embodiment provides a kind of preparation method based on the high-quality blue indigo pulp of lactic acid bacteria fermentation, such as figure 1 As shown, the method includes the following steps:

[0035] 1) Dilute the syrup into 120 catties of clear water at a mass ratio of 1:750;

[0036] 2) 2ml pre-cultured Bulgarian lactic acid bacteria were inoculated into the diluted medium; the number of colonies of the lactic acid bacteria was 10 8 CFU / mL.

[0037] 3) Sealed fermentation for 2 days, draw 1ml of the bacterial culture, dilute it 10 times, draw 200μl and spread it on the MRS-agar medium plate, cultivate it at 37°C for 16 hours, and calculate the number of viable bacteria in the bacterial culture to reach 1.6 ×10 8 CFU; Utilize the PH acidity meter (Starter 2C U.S. Ohaus imports PH acidity meter) to measure the pH of the bacterial liquid culture to 4.3;

[0038] Glycolysis of lactic acid creates a low pH environment and produces the biological enzyme glyc...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method based on the high-quality blue indigo pulp of lactic acid bacteria fermentation, described method comprises the steps:

[0046] 1) Dilute the brown sugar into 160 jin of clear water with a mass ratio of 1:500;

[0047] 2) 2ml pre-cultured Bulgarian lactic acid bacteria were inoculated into the diluted medium; the number of colonies of the lactic acid bacteria was 10 7 CFU / mL.

[0048] 3) Sealed fermentation for 2 days, draw 1ml of the bacterial culture, perform doubling dilution, draw 200 μl and spread it on the MRS-agar medium plate, cultivate at 37°C for 16 hours, and calculate the number of viable bacteria in the bacterial culture to reach 1× 10 8 CFU uses a PH acidity meter (Starter 2C American Ohaus imported PH acidity meter) to measure the pH of the bacterial culture to 4;

[0049] 4) powdering the indigo; the mass ratio of the indigo to the fermentation broth is 1:14; mixing the pulverized indigo wit...

Embodiment 3

[0054]The present embodiment provides a kind of preparation method based on the high-quality blue indigo pulp of lactic acid bacteria fermentation, described method comprises the steps:

[0055] 1) Dilute the syrup into 80 catties of clear water at a mass ratio of 1:1000;

[0056] 2) 2ml pre-cultured Bulgarian lactic acid bacteria were inoculated into the diluted medium; the number of colonies of the lactic acid bacteria was 10 9 CFU / mL.

[0057] 3) Sealed fermentation for 2 days, draw 1ml of bacterial culture, perform doubling dilution, draw 200μl and spread it on the MRS-agar medium plate, incubate at 37°C for 16 hours, and calculate the number of viable bacteria in the bacterial culture to reach 2× 10 8 CFU; Utilize PH acidity meter (starter 2C U.S. Ohaus imports PH acidity meter) to measure the pH of bacterial liquid culture to 4.5;

[0058] 4) Pulverize the indigo; the mass ratio of the indigo to the fermentation broth is 1:10; mix the pulverized indigo with the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com